7 mounting brackets, Mounting brackets -17, Mounting brackets – KEYENCE GL-RHG Series User Manual

Page 65

3-17

GL-RHG-M-NO3-E

In

sta

llatio

n

to

a Mac

h

in

e

3

3-7

Mounting Brackets

Point

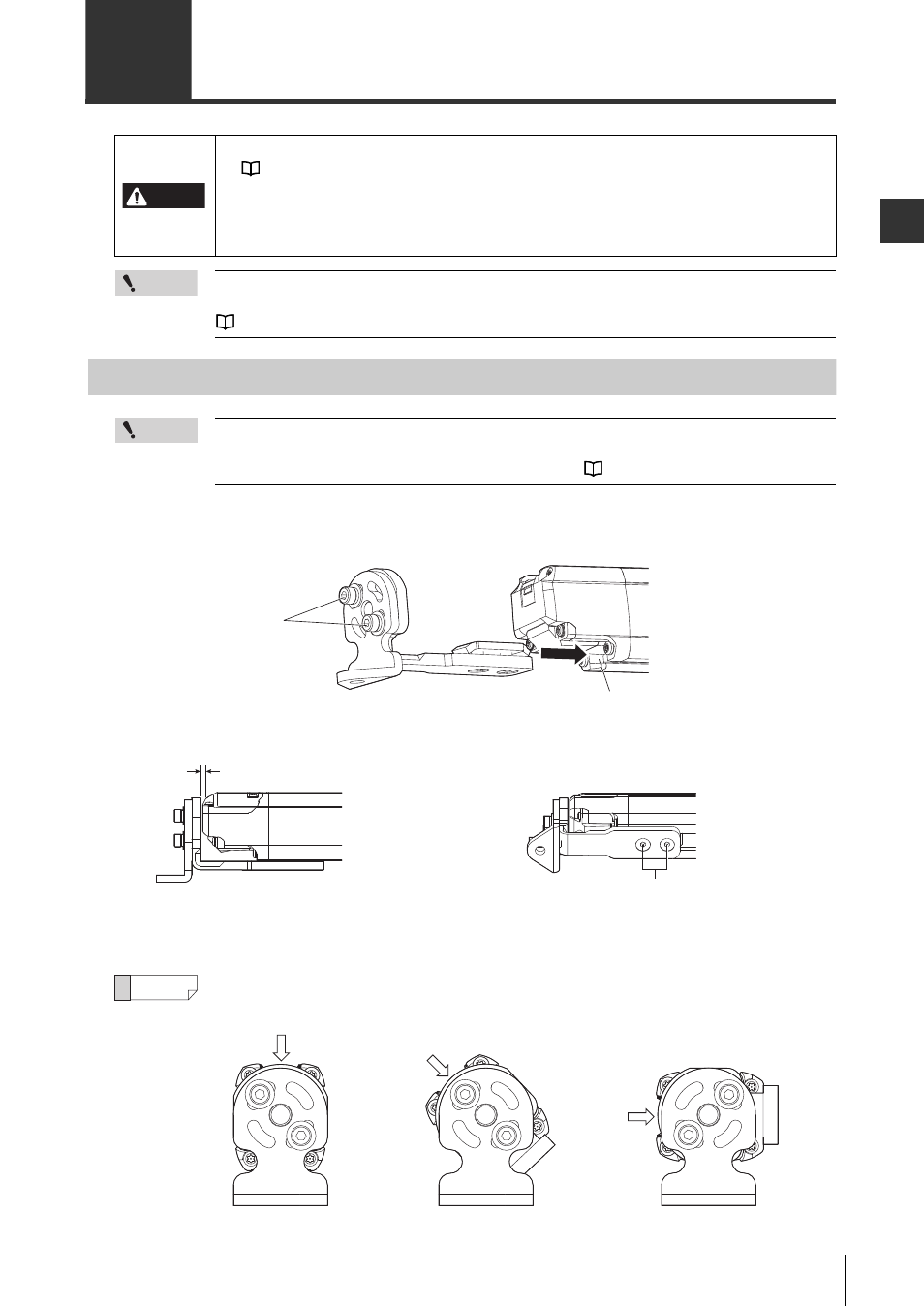

Connect the cables to the GL-RHG before connecting the mounting brackets. If the mounting

brackets are connected before the cables, the cable may be disconnected or poor connection.

"Cable Installation" (page 3-14)

Adjustable angle mounting bracket (GL-RB01/GL-RB02)

Point

If the length for a single GL-RHG unit is 1280 mm or greater, use the antivibration bracket for

the adjustable angle mounting bracket additionally as an intermediate support bracket.

For more information about the mounting position, see

1

Insert the adjustable angle mounting bracket into the GL-RHG along the groove on the back side,

as shown in the following image.

2

Secure standard mounting bracket A to the GL-RHG with hexagon socket bolt 2 on the back side.

3

Adjust the installation angle of the GL-RHG for optical alignment and secure the standard mount-

ing bracket A to the GL-RHG with the hexagon socket bolt 1.

Reference

There are three types of mounting directions according to the positions of hexagon socket bolt 1.

Additionally, the angle can be adjusted precisely in the range of ±25°

DANGER

The proper installation of the device should be verified according to the procedure outlined

in

"Regular (periodical) inspection" (page A-9) in the event that maintenance requires

the removal of the device from its target equipment or the adjustment of its installation

position after its initial installation onto that target equipment. Failure to follow this

installation instruction may result in significant harm to the machine operators, including

serious injury or death.

Hexagon socket bolt 1

(M4, length: 10 mm,

width across flat: 3 mm)

Groove on the back side

The space between bracket and the GL-RHG must be 2 mm or less.

Hexagon socket bolt 2 (M5, Length: 8 mm, width across flat: 3 mm)

A recommended tightening torque of 3 N•m

Detection surface

Back mounting

Detection surface

Detection

surface

45° mounting

90° mounting