Zexample for supplemental gl-rhg installation – KEYENCE GL-RHG Series User Manual

Page 57

3-2

Safety Distances

3-9

GL-RHG-M-NO3-E

In

sta

llatio

n

to

a Mac

h

in

e

3

z

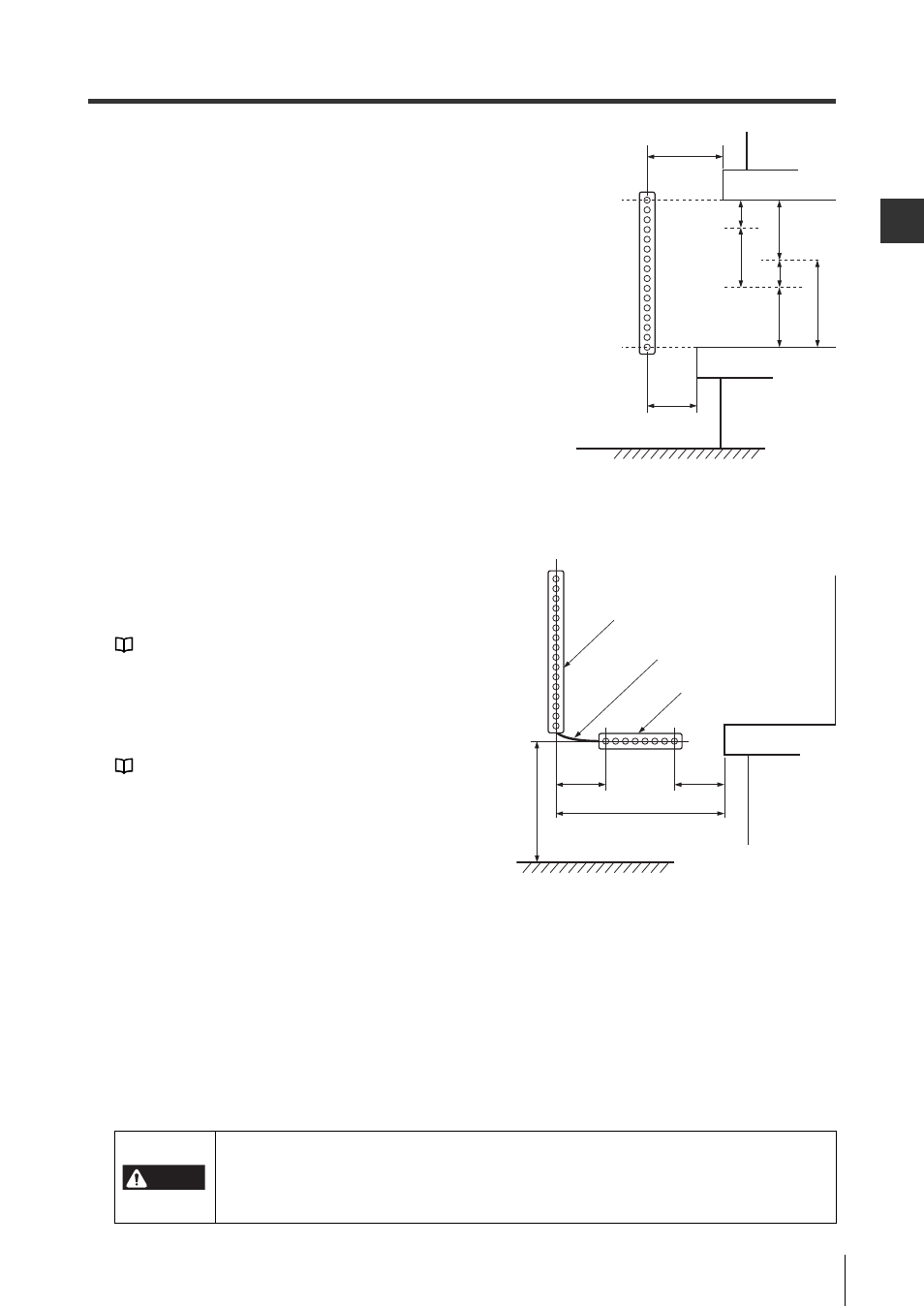

Safety light curtain installation position

(for machine press)

A

: Slide adjustment amount

S

: Length of strokes

H

D

: Die height

H

D

- A : Minimum die height

D

: Safety distance

Gap

: 75mm or less

(If the length exceeds 75 mm, an additional

guard, etc. must be installed.)

Top optical axis position: Height of slide bottom surface at

slide's highest position

If the height of slide bottom surface

at slide's highest position from FL

is less than 1400mm, the position

is 1400mm. (Longer than S + H

D

)

If it is more than 1700mm, the posi-

tion is 1700mm. (Shorter than S + H

D

)

Safety light curtain protection height: S + H

D

From the bolster top surface to the slide bottom surface at slide's

highest position

Bottom optical axis position: Height of bolster top surface

z

Example for supplemental GL-RHG installation

It is recommended to make series connection in case

where supplemental GL-RHG is used for additional pro-

tection. Series connection can prevent light interference.

"Series connection" (page 2-3)

(1) Install GL-RHG so that the gap between main unit

and sub unit must be 75mm or less and the gap

between sub unit and front edge of the bolster.

(2) Install sub unit almost horizontally at the waist height

of operator.

For details, refer to the "Management guideline of press

machine safety device" (Ministry of Health, Labour and Welfare

No. 446-2 of July 9, 1993) and "Application of amendments of a

part of the standard for the mechanical structure of power

press and a part of the structural standard of press machine

safety device and shearing machine safety device" (Ministry of

Health, Labour and Welfare No. 0218-3 of February 18, 2011).

Example 5 When using GL-RHG as safety device for shearing machine (paper cut-

ting machine) in Japan

Safety distance calculation according to the Construction standard for press machine and shear-

ing machine safety device

Make sure to observe the following according to the Construction standard for press machine and shearing

machine safety device (Notification of Ministry of Health, Labour and Welfare No. 102, September 21, 1978).

•

When the safety distance exceeds 270 mm, be sure to install the supplementary axis between the main

optical axis and the blade. The safety distance in this context means the horizontal distance between the

vertical plane including the optical axis of GL-RHG and dangerous zone (hazard source).

•

The height of the optical axis from the table surface of shearing machine (paper cutting machine) must

be 67% or less of safety distance and 180 mm or less.

D

A

S

S

A

H

D

- A

H

D

Top optical

axis position

Bottom optical

axis position

Gap

FL

Bolster

Slide

Main unit

Connection cable

Sub unit

Bolster

75 mm

or less

75 mm

or less

Length with which an operator can enter

Waist

height

DANGER

When using a supplementary axis, install the supplementary axis according to the above

descriptions so that the user of machine does not stand between the machine and GL-RHG or enter

the danger zone of machine by detouring the protection area of GL-RHG. Failure to observe this

warning may result in extremely dangerous situations including death or serious injury of users.