High altitude (48pg and pm), Main burners (48pg and 48pm) – Carrier 48/50PM C16-28 User Manual

Page 92

92

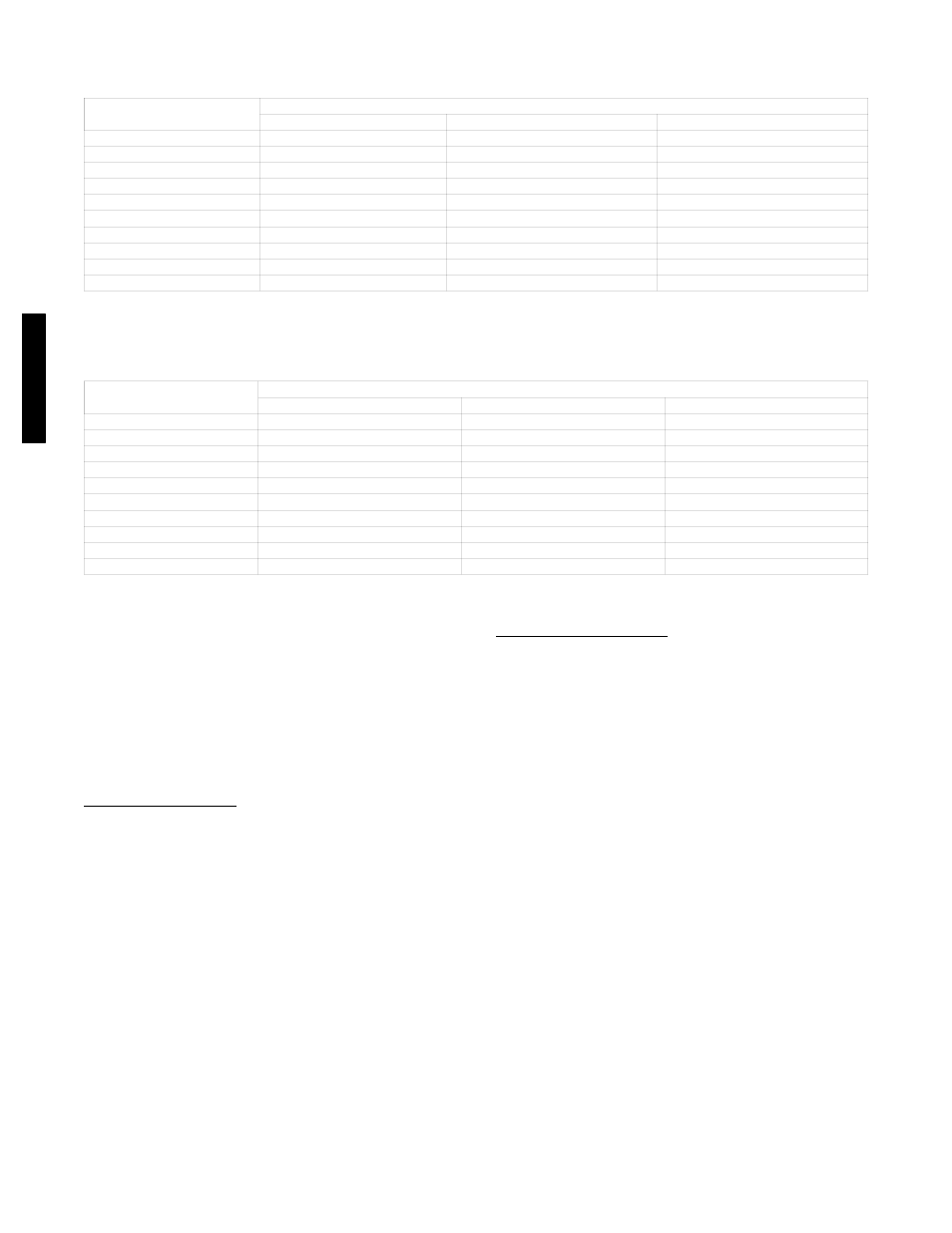

Table 29 – Altitude Compensation* − 48PM16−20

NATURAL GAS

ELEVATION

(ft)

NATURAL GAS ORIFICE SIZE†

Low Heat (D,L)

Medium Heat (E,M)

High Heat (F,N)

0‐1,999

29

30

29

2,000

29

30

29

3,000

30

31

30

4,000

30

31

30

5,000

30

31

30

6,000

30

31

30

7,000

31

32

31

8,000

31

32

31

9,000

31

32

31

10,000

32

33

32

*As the height above sea level increases, there is less oxygen per cubic foot of air. Therefore, heat input rate should be reduced at higher altitudes. Includes a

4% input reduction per each 1000 ft.

†Orifices available through the local Carrier dealer.

PROPANE GAS

ELEVATION

(ft)

PROPANE GAS ORIFICE SIZE†

Low Heat (D,L)

Medium Heat (E,M)

High Heat (F,N)

0‐1,999

35

38

35

2,000

36

39

36

3,000

36

39

36

4,000

37

40

37

5,000

37

40

37

6,000

38

41

38

7,000

39

42

39

8,000

40

43

40

9,000

41

44

41

10,000

42

45

42

*As the height above sea level increases, there is less oxygen per cubic foot of air. Therefore, heat input rate should be reduced at higher altitudes. Includes a

4% input reduction per each 1000 ft.

†Orifices available through the local Carrier dealer.

High Altitude (48PG and PM)

For high altitude applications greater than 2,000 ft the heat input

rate should be reduced. The higher the altitude is above sea level,

the less oxygen is in the air. See Table 28 for orifice sizing. A high

altitude kit is available to convert unit for altitudes up to 7,000 ft.

Main Burners (48PG and 48PM)

For all applications, main burners are factory set and should require

no adjustment.

Main Burner Removal

1. Shut off (field-supplied) manual main gas valve.

2. Shut off power to unit.

3. Open gas section access door.

4. Disconnect gas piping from gas valve inlet.

5. Remove wires from gas valve.

6. Remove wires from rollout switch.

7. Remove sensor wire and ignitor cable from IGC board.

8. Remove 2 screws that hold the burner assembly to vestibule

plate. For 48PM16−28 units, also remove the 2 screws se-

curing the manifold bracket to the basepan.

9. Rotate the burner/manifold assembly to the right, away

from the flue extension and lift burner/manifold assembly

out of unit.

Cleaning and Adjustment

1. Remove burner rack from unit as described in Main Burner

Removal section above.

2. Inspect burners, and if dirty, remove burners from rack. The

two outer burners have the flame crossover closed off in

order to prevent gas flow from exiting the sides of the

burner assembly. To prevent ignition problems, make sure

the outer burners are returned to their original position when

done servicing.

3. Using a soft brush, clean burners and crossover port as

required.

4. Adjust spark gap. (See Fig. 70.)

5. Reinstall burners on rack.

6. Reinstall burner rack as described above.

48/50PG and PM