Optimum start setup, Sensor setup, Optimum start setup sensor setup – KMC Controls FlexStat Operation Guide User Manual

Page 9: Sensor setup on

FlexStat

9

Operation Guide, Rev. R

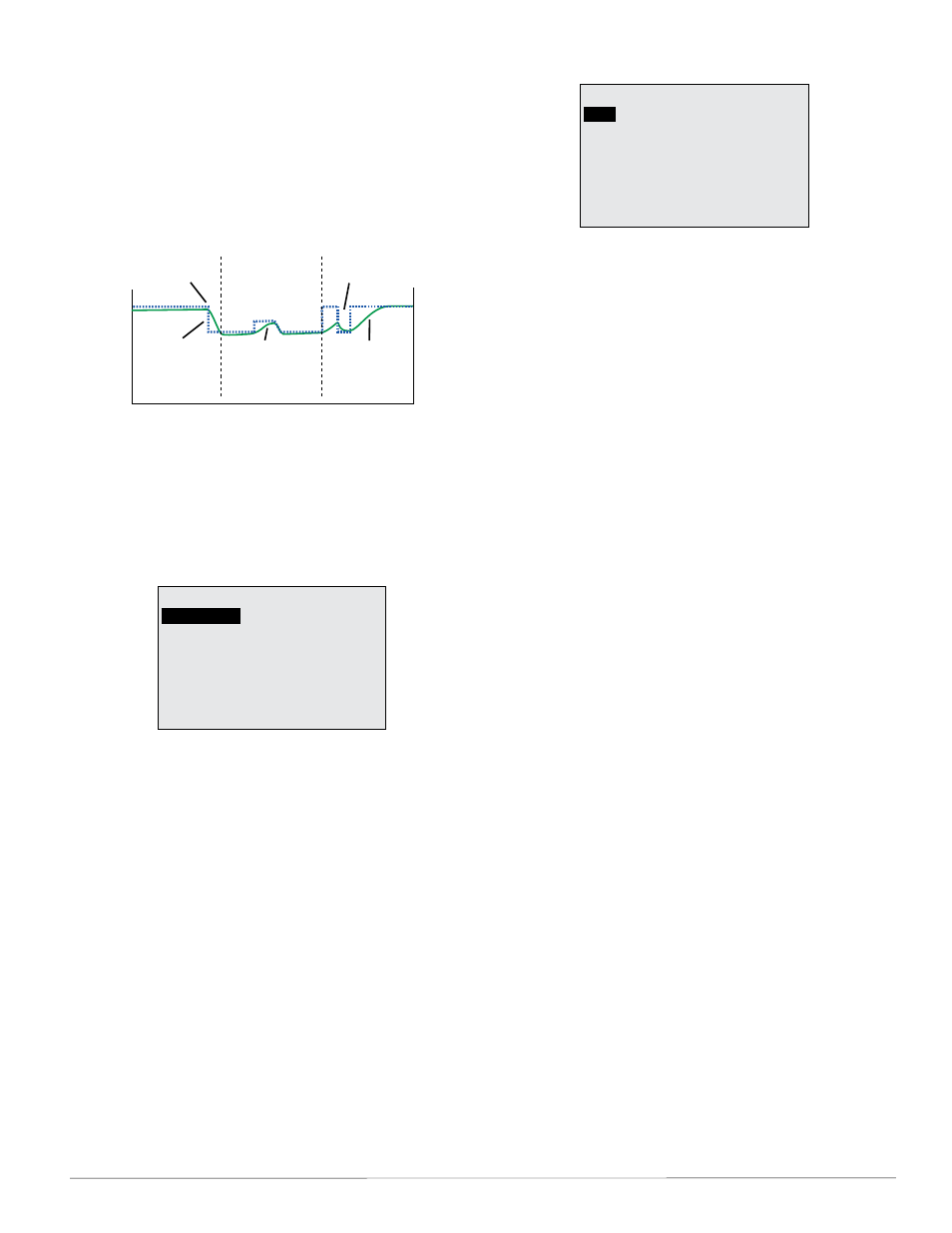

reverting from Standby back to Occupied

mode (although it may still take some

time for the room to reach its normal

.

NOTE: DCV is only available in models with the

built-in CO

2

sensor.

Occupancy

Standby*

Cooling

Setpoint

Scheduled

On Time

Space

Temperature

Scheduled

Off Time

Optimum

Start

Unoccupied

Unoccupied

Occupied

Occupancy

Override*

(*Available only on FlexStats with motion sensors)

The State field monitors whether motion has been

detected during the last scan of the motion sensor

input (BI6). Detected motion will show an “occu-

pied” state. This can be used during troubleshooting

to determine if motion is being detected.

Optimum Start Setup

OPTIMUM START

OPT START:

DISABLE

When Optimum Start is enabled, the FlexStat soon

“learns” the amount of time required to reach

the setpoint from the setback/setup temperature.

It will then adjust the actual start time needed

to reach the desired setpoint at the beginning

of the scheduled On times. (See the chart in the

(Advanced) Motion Sensor section.) It will also make

seasonal temperature adjustments if an outside air

temperature sensor is connected appropriately.

NOTE: For maximum efficiency, if Optimum

Start is enabled, set times in schedules for

when the room temperature should reach

the setpoint, not when heating/cooling

equipment should start (which would be

earlier). See

NOTE: For details of the energy-saving calculations

performed, see the Optimum Start section

in the relevant Sequence of Operation in the

Sensor Setup

SENSOR SETUP

IN 2:

IN 9: CO2

SPACE TEMP: REMOTE

-- IN 1 IS ONBOARD

-- IN 7 IS REMOTE

DISCH AIR TEMP

Input 7 (AI7) can be configured for a remote space

temperature sensor. Then space temperature can be

configured for onboard (internal AI1), remote (AI7),

averaging of the two, the lowest reading, or the high-

est reading. To calibrate and change the thermistor

type, see

Input 2 (AI2) can be configured for discharge air

temperature (DAT and Type III thermistor is the

default), fan status (dry contact), or unused.

• If AI2 is set for discharge air temperature, a

trend log is automatically created and monitors

the discharge air temperature, but it has no effect

on operation. The sensor can be calibrated and

changed from the default Type III thermistor to a

• If AI2 is set for fan status and no closed contact is

detected when there is a call for fan operation, a

Fan Fail Alarm is created. See

.

• If AI2 is set for unused, built-in applications will

not use it, but the input would be available for

custom programming.

In BAC-12xxxx/13xxxx/14xxxx models, Input 9 (AI9)

can be configured for an external KMC SAE-10xx

CO

2

sensor. For more information, see

Control Ventilation) Setup on page 11

See also

.