KMC Controls CSC-2000 Series User Manual

Installation guide, Reset volume controllers, Csc-2000 series overview

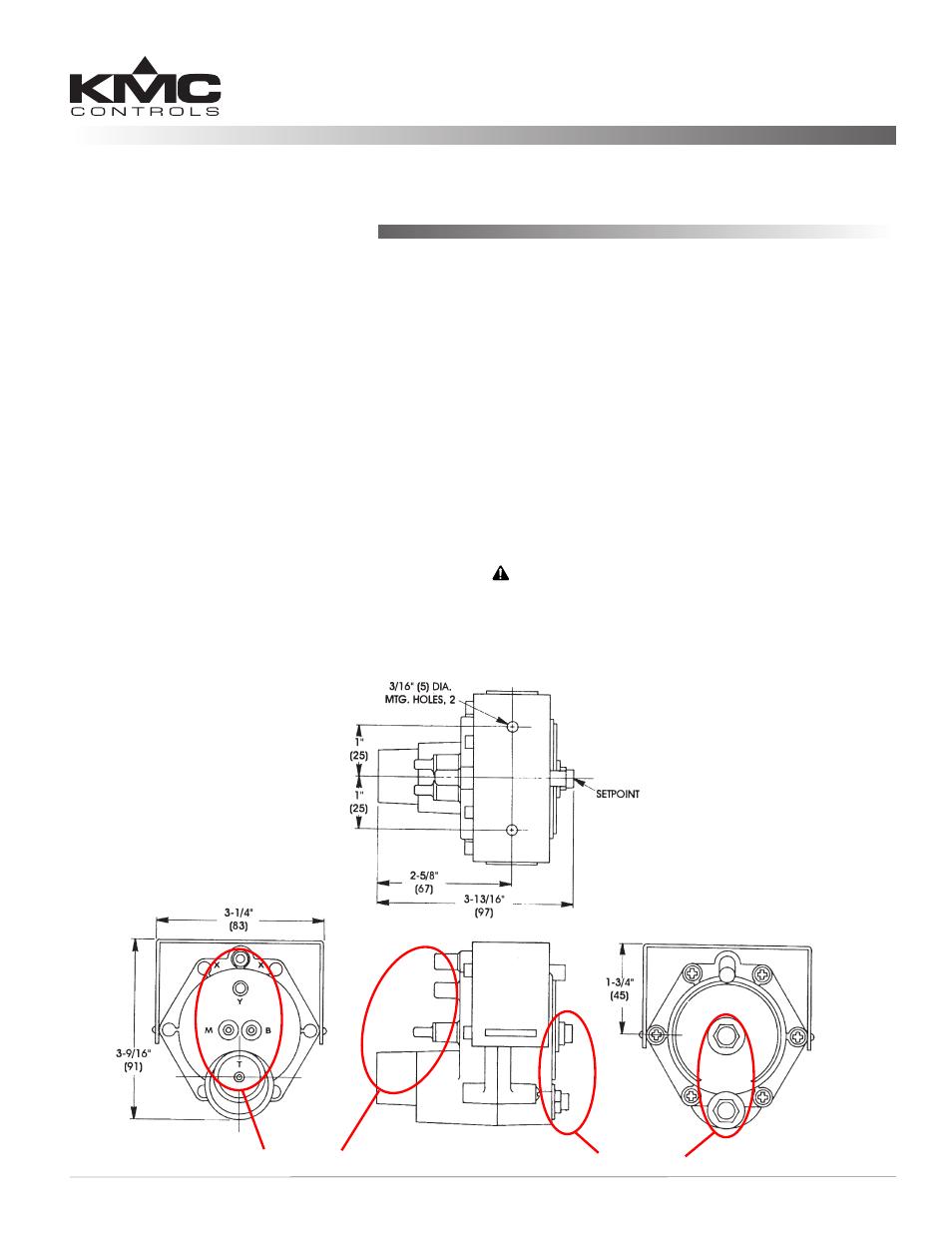

CSC-2000 Series Reset Volume Controllers

1

Installation Guide

Installation Guide

Reset Volume Controllers

CSC-2000 Series

Connections

Adjustments

Any sequencing with other controllers, valves, or

pneumatic-electric relays must be sequenced with

the controller’s reset range, not the actuator’s spring

range.

These controllers are typically used on single-duct

applications but may be found in dual-duct appli-

cations. When working on dual-duct applications

it may be necessary to work on one duct at a time

while closing off the other.

The CSC-2000 series controllers are position sensi-

tive. See the Mounting section on the next page for

the proper vertical/horizontal orientation for the dif-

ferent models.

CAUTION

Pneumatic devices must be supplied with clean,

dry control air. Any other medium (e.g., oil or

moisture contamination) will cause the device

to fail.

CSC-2000 Series Overview

The CSC-2000s are differential-pressure (∆P), sub-

master controllers with adjustable minimum and

maximum airflow settings. A master controller,

typically a room thermostat, resets the CSC velocity

setpoint.

CSC-2000s are available as direct acting for normally

open VAV terminal units, and reverse acting for nor-

mal closed VAV terminal units. Each unit is equipped

with separate adjustment knobs for minimum and

maximum airflow settings. CSC-2001/2002s are

equipped with 0–10 reference dials, while all others

have blind adjustments. Calibrate all models using

standard airflow measuring equipment.

The spring range of the actuator does not matter

to the controller. However, sufficient main air is

required to provide the actuator with enough force

to operate the damper/linkage.