3 rack data – Metrohm 788 IC Filtration Sample Processor User Manual

Page 102

4 Operation

788 IC Filtration Sample Processor

94

When a sample series is started the 788 IC Filtration Sample Processor

first runs the rack automatically into the normal starting position so that

it is always ensured that the vessel positions correspond with the inter-

nal position table of the current rack.

The rack code is used for automatic rack recognition. A code can be

assigned only once. The standard rack supplied by Metrohm already

have a predefined code. The rack code is a 6-place binary pattern with

the digits 0 and 1 and this has to correspond to the order of the rod

magnets. The digit 1 stands for a magnet which is inserted and 0 signi-

fies that no magnet is inserted. 63 different codes are possible (000001

to 111111).

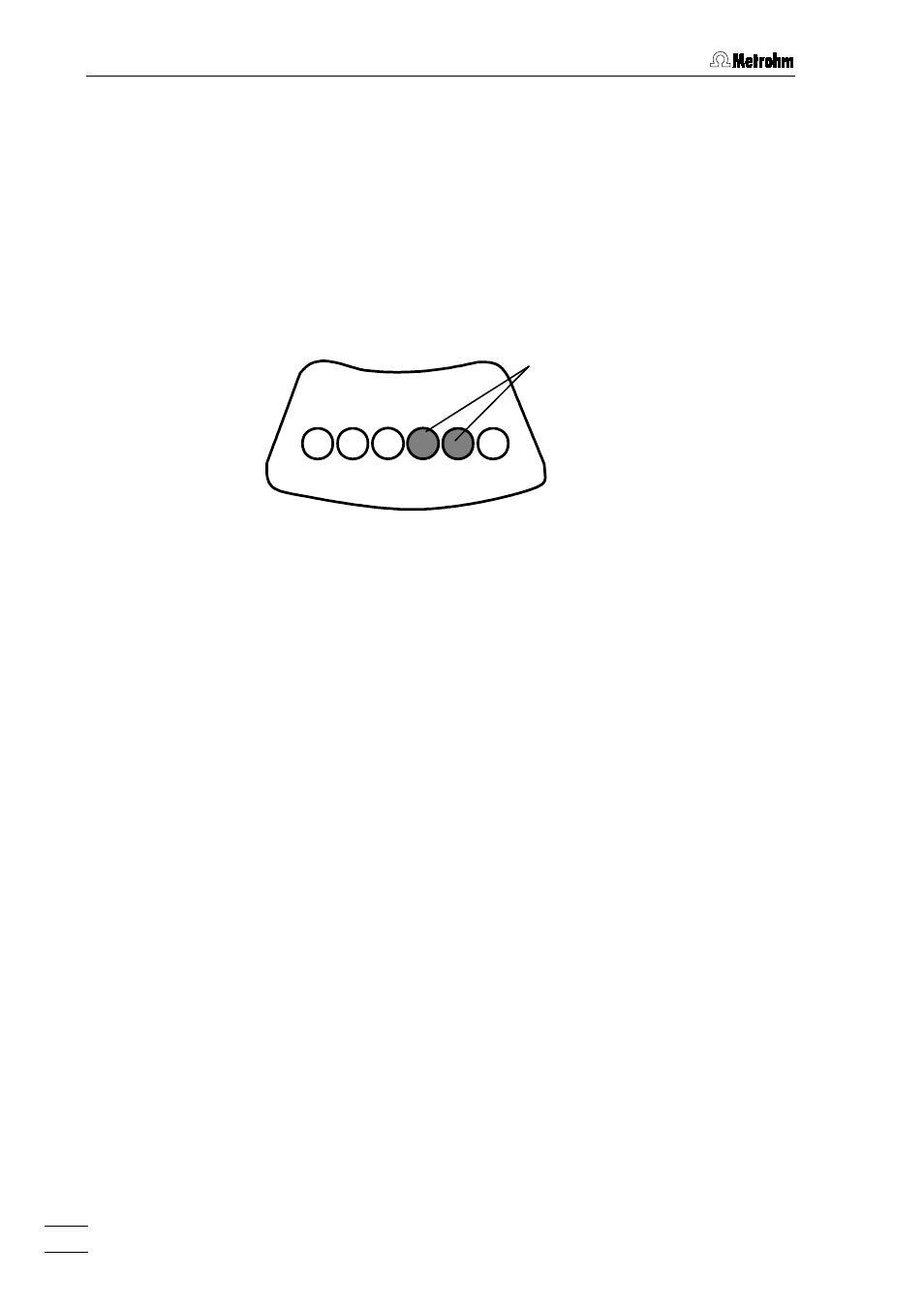

Magnets inserted

In this example

the code is:

000110

Rack bottom view

In order to assign a certain sample rack for different applications, cer-

tain properties or recognition data can be defined for up to 16 racks.

This is useful when a certain beaker size or the size of the sample se-

ries or a certain course of processing is to be predefined in an applica-

tion.

4.5.3 Rack

data

The following recognition data can be defined for each rack:

Rack number

unique identification

Code

automatic rack recognition

Type

rack type / position table

Work position

working height of the needle

Rinse position

rinsing height of the needle

Shift position

turning height of the needle

Special position

additional height of the needle

Special beaker position reserved beaker positions

The

Rack number serves to identify a rack. It can be chosen from 1 to

16. In a method a particular rack number can be assigned to the proc-

ess sequences (see section 4.3.2). This ensures that if the wrong sam-

ple rack is used, the automatic rack recognition will realize this and is-

sue a warning to the user.