Motor overload – Rockwell Automation 20A PowerFlex 70EC/700VC User Manual

Page 59

Motor Overload

55

Motor Overload

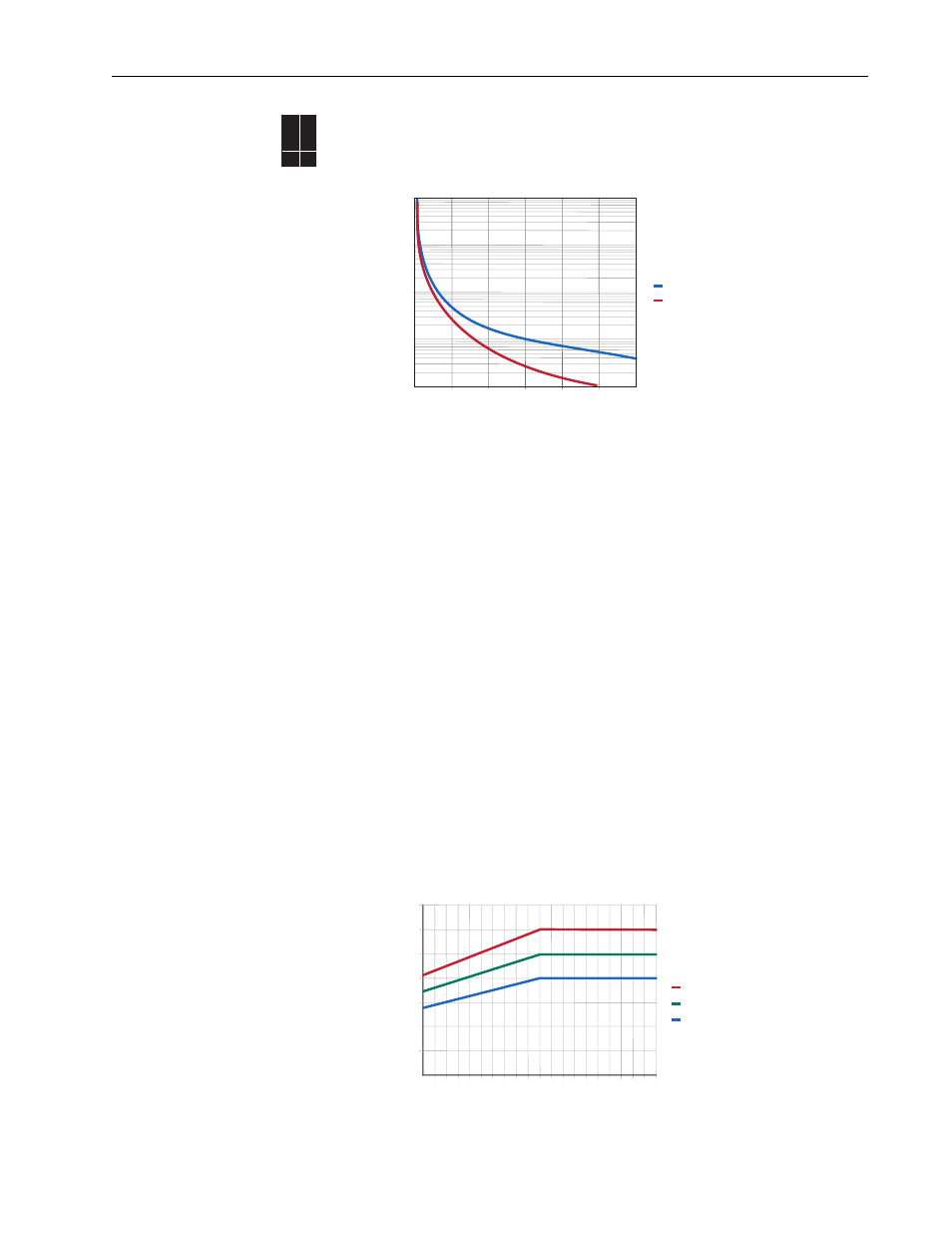

The motor overload protection feature uses an IT (inverse time) algorithm to model

the temperature of the motor and follows the same curve as a physical class 10

overload device.

[Motor NP FLA] is used by the overload feature to establish the 100% level (y axis)

shown in the graph above.

Setting the correct bit in [Fault Config x] to zero disables the motor thermal

overload. For multimotor applications (more than one motor connected to one

drive), separate external overloads for each motor are required, and the drive’s

motor overload can be disabled.

Operation of the overload is based on three parameters; [Motor NP FLA], [Motor

OL Factor] and [Motor OL Hertz].

1. [Motor NP FLA] is the base value for motor protection.

2. [Motor OL Factor] is used to adjust for the service factor of the motor. Within

the drive, motor nameplate FLA is multiplied by motor overload factor to select

the rated current for the motor thermal overload. This can be used to raise or

lower the level of current that will cause the motor thermal overload to trip

without the need to adjust the motor FLA. For example, if motor nameplate

FLA is 10 Amps and motor overload factor is 1.2, then motor thermal overload

will use 12 Amps as 100%.

Important: Some motors have a service factor that is only for use with sine

wave (non-drive) power. Check with the motor manufacturer to

see if the nameplate service factor is valid or must be reduced

when operated by a drive.

70EC

700VC

700H

✔ ✔

Motor Overload Curve

10

100

1000

10000

100000

100

125

150

175

200

225

250

Full Load Amps (%)

Trip Time

(Seconds)

Cold

Hot

Changing Overload Factor

20

40

60

80

100

120

140

0

10

20

30

40

50

60

70

80

90 100

% of Base Speed

Contin

uous Rating

OL % = 1.20

OL % = 1.00

OL % = 0.80