Rockwell Automation 20A PowerFlex 70EC/700VC User Manual

Page 106

102

Speed Regulation

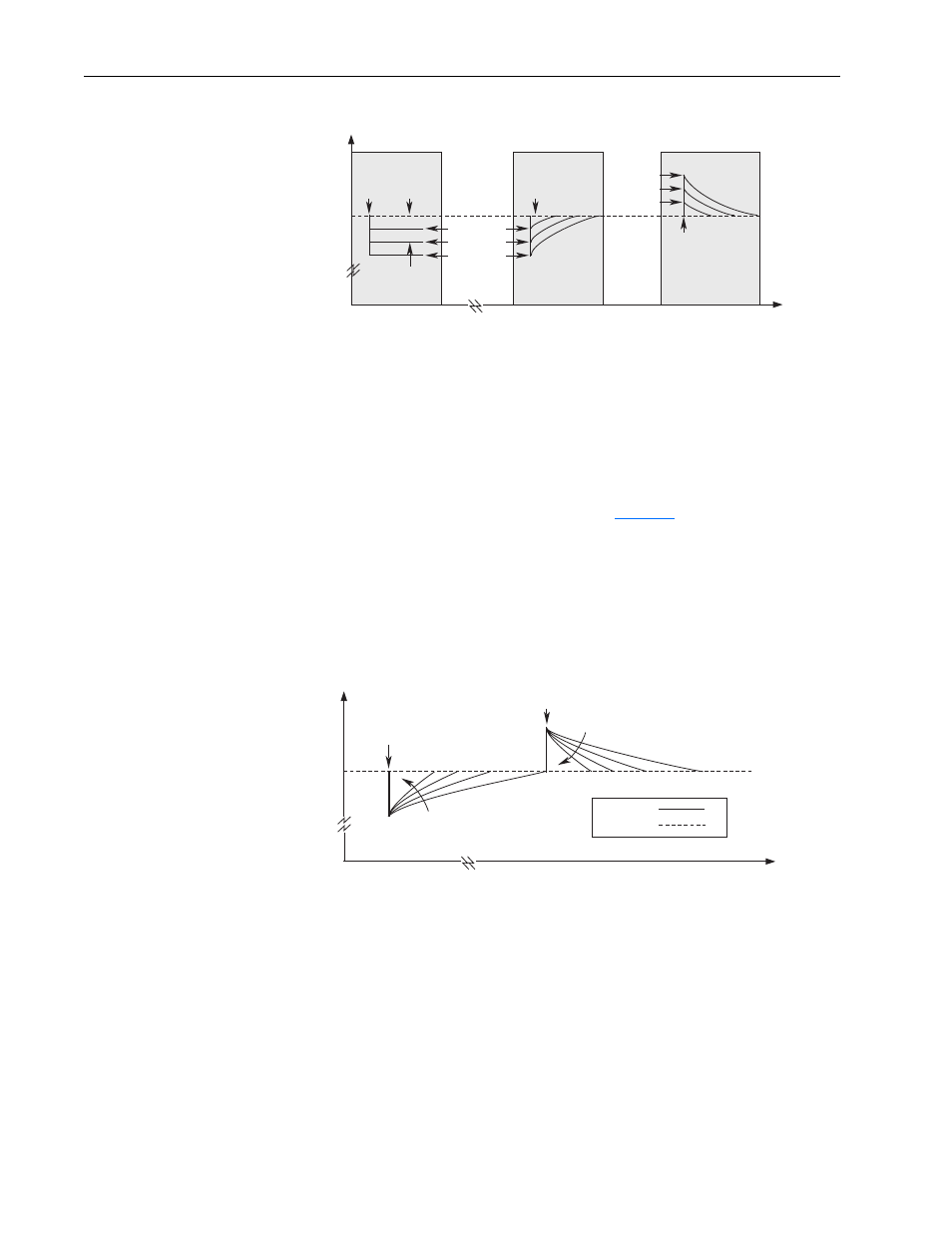

Figure 18 Rotor Speed with/without Slip Compensation

Internally, the drive converts the rated slip in RPM to rated slip in frequency. To

more accurately determine the rated slip frequency in hertz, an estimate of flux

current is necessary. This parameter is either a default value based on motor

nameplate data or the auto tune value. The drive scales the amount of slip

compensation to the motor rated current. The amount of slip frequency added to the

frequency command is then scaled by the sensed torque current (indirect

measurement of the load) and displayed.

Slip compensation also affects the dynamic speed accuracy (ability to maintain

speed during “shock” loading) as illustrated in

Figure 19

. Initially, the motor is

operating at some speed and no load. At some time later, an impact load is applied

and the rotor speed decreases as a function of load and inertia. And finally, the

impact load is removed and the rotor speed increases momentarily until the slip

compensation is reduced based on the applied load.

The responsiveness to an impact load can be adjusted through [Slip Comp Gain];

however too large of a gain can cause unstable operation and overshoot.

Figure 19 Rotor Speed Response Due to Impact Load and Slip Com Gain

Slip Compensation

Active

Open Loop

Mode

Time

Rotor Speed

0

0

Load

Applied

Load

Applied

No Load

Slip @

F.L.A.

0.5 p.u. Load

1.0 p.u. Load

1.5 p.u. Load

0.5 p.u. Load

1.0 p.u. Load

1.5 p.u. Load

Slip Compensation

Active

Load

Removed

Time

Speed

0

0

Impact Load

Applied

Impact Load

Removed

Increasing Slip

Comp Gain

Increasing Slip

Comp Gain

Rotor Speed

Reference