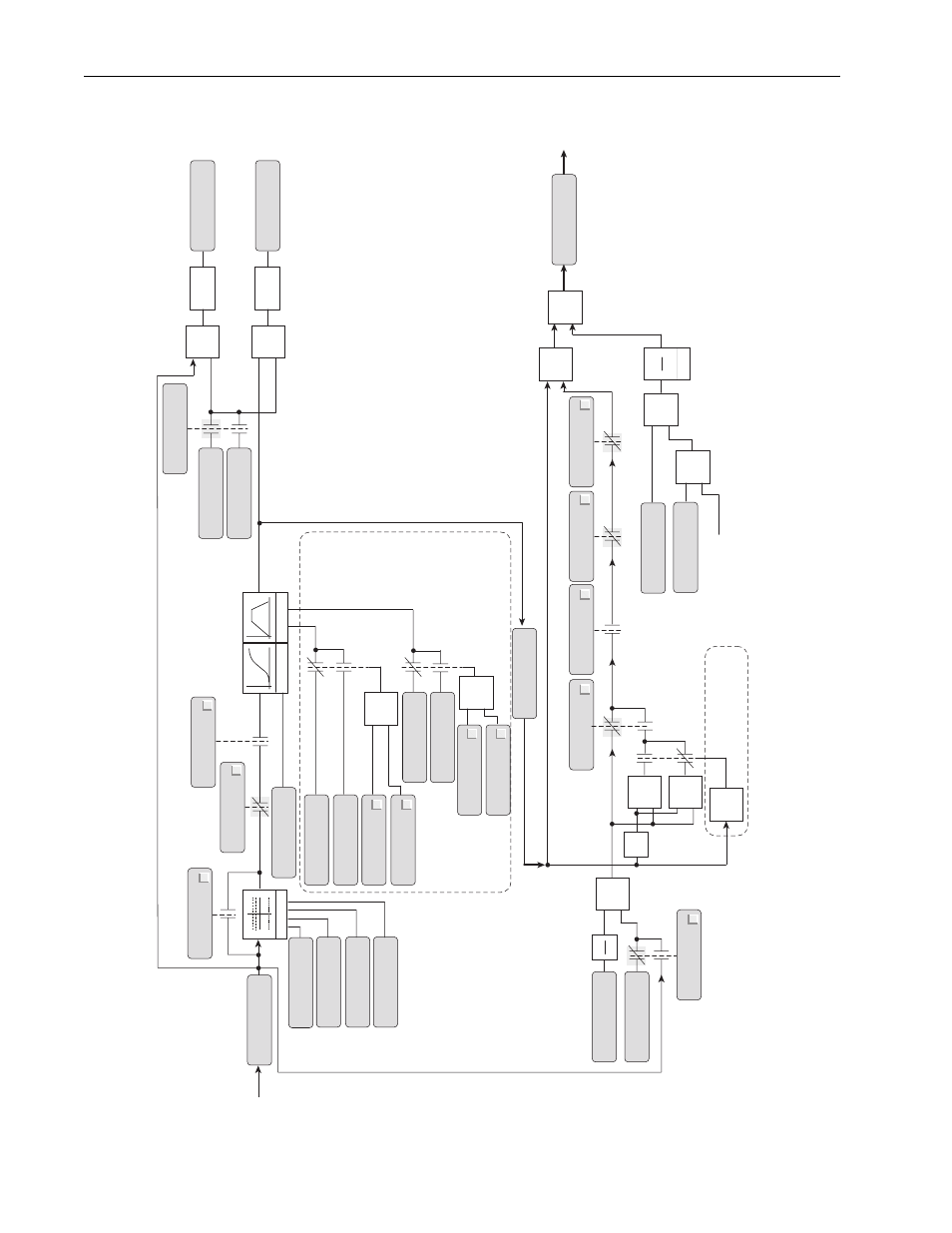

Speed ram p & process t rim – Rockwell Automation 20A PowerFlex 70EC/700VC User Manual

Page 144

140

PowerFlex 70EC Block Diagrams

0.0 Hz

2 - Commanded Freq

Bit 2 - Jog

271 - Drive Logic Rslt

0.0 Hz

84 - Skip Frequency 1

0.0 Hz

85 - Skip Frequency 2

0.0 Hz

86 - Skip Frequency 3

0.0 Hz

87 - Skip Freq Band

Bit 4 - Stopping

210 - Drive Status 2

Bit 1 - Active

210 - Drive Status 2

0.0 %

146 - S Curve %

10.0 Secs

140 - Accel Time 1

10.0 Secs

141 - Accel Time 2

Bit 8 - Accel 1

271 - Drive Logic Rslt

Bit 9 - Accel 2

271 - Drive Logic Rslt

10.0 Secs

142 - Decel Time 1

10.0 Secs

143 - Decel Time 2

Bit 10 - Decel 1

271 - Drive Logic Rslt

Bit 11 - Decel 2

271 - Drive Logic Rslt

0.0 Hz

22 - Ramped Speed

Max Freq

298 - DPI Ref Select

130.0 Hz

55 - Maximum Freq

60.0

82 - Maximum Speed

0

272 - Drive Ref Rslt

0

273 - Drive Ramp Rslt

0.0 %

138 - PI Output Meter

130.0 Hz

55 - Maximum Freq

Bit 9 - % of Ref

124 - PI Configuration

Bit 4 - Zero Clamp

124 - PI Configuration

Bit 0 - PI Enabled

134 - PI Status

Bit 8 - Torque Trim

124 - PI Configuration

Bit 0 - Excl Mode

124 - PI Configuration

0.0 RPM

152 - Droop RPM @ FLA

0.00 Amps

4 - Torque Current

0.0 Hz

23 - Speed Reference

Max

Min

<0

X

X

X

NP T

orque

Current

÷

X

X

+

+

+

–

X

+

X

+

R

S

R

S

1

100

–1

Skip Bands

1

0

Ramp

S Cur

ve

1

0

32767

32767

ω

s +

ω

LP

ass

Note:

If this command is

Negativ

e then change state

.

Note:

If an

y of

the Dr

iv

e Logic Rslt

par

ameters change

from a 1 to a 0,

latching will occur

,

holding last state

.

Speed Ram

p & Process T

rim