Commonly used tools, Installation and service tools – Rockwell Automation 21G PowerFlex 750-Series AC Drives User Manual

Page 6

6

Rockwell Automation Publication 750-IN001N-EN-P - April 2014

PowerFlex 750-Series AC Drives

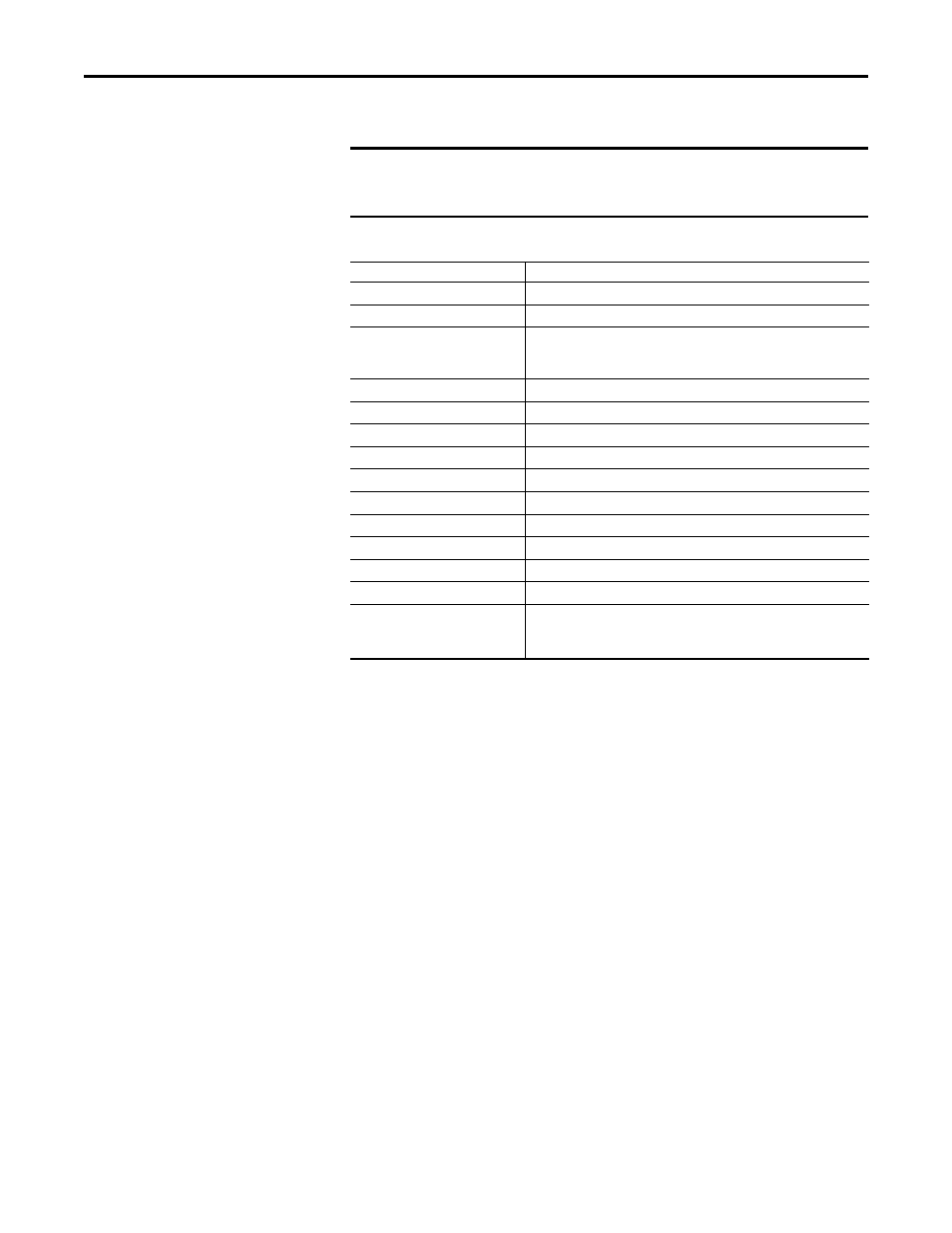

Commonly Used Tools

Installation and Service Tools

This list covers the tools needed for drive installation.

IMPORTANT

Care must be taken to be sure that tools and/or hardware components do not fall into

open drive assemblies. Do not energize the drive unless all loose tools and/or hardware

components have been removed from the drive assemblies and enclosure.

Tool Description

Details

ESD-protected place of work

Working surface, Floor covering, seat and ground connections

ESD-protective clothing

Wrist wrap, shoes, overall clothing (coat)

Multi meter

Digital multi meter, capable of AC and DC voltage, continuity, resistance,

capacitance measurements, and forward diode bias tests. Fluke model 87 III or

equivalent.

Allen socket wrench

4 mm, 5 mm

Allen socket wrench extension

254 mm (10 in.)

Flat nose screw driver

5 mm (0.19 in.), 6.4 mm (0.25 in.), 9.5 mm (0.375 in.), #1, #2

Hexalobular screw driver/bit

#15, #20, #25, #40, #45

Hexagonal socket wrench

7 mm, 8 mm, 10 mm, 12 mm, 13 mm, 17 mm, 18 mm

Combination wrench

10 mm, 17 mm

Phillips® screw driver/bit

(1)

(1) Phillips and Pozidriv are registered trademarks of the Phillips Screw Company.

#2, 492-C

#2, M3 x 7

Torque wrench

1...12 N•m (8.8…106 lb•in)

Torque wrench

6...50 N•m (53…443 lb•in)

Roll-out cart

20-750-CART1-F8

Note: The roll-out cart is required to remove the Frame 8 and larger drive

assembly from the enclosure.