Absolute vs. incremental dimensions, Continuous milling, 1 con v ersational pr ogr a mming – ACU-RITE MILLPWRG2 User Manual

Page 92

74

6 Programming

6.1 Con

v

ersational Pr

ogr

a

mming

Absolute vs. Incremental Dimensions

MILLPWR

G2

allows both absolute and incremental dimensions to be

entered. A dimension measured from the point you defined as datum

is an absolute dimension. A dimension measured from any other point

is an incremental dimension. See "Absolute and incremental work

piece positions" on page 25.

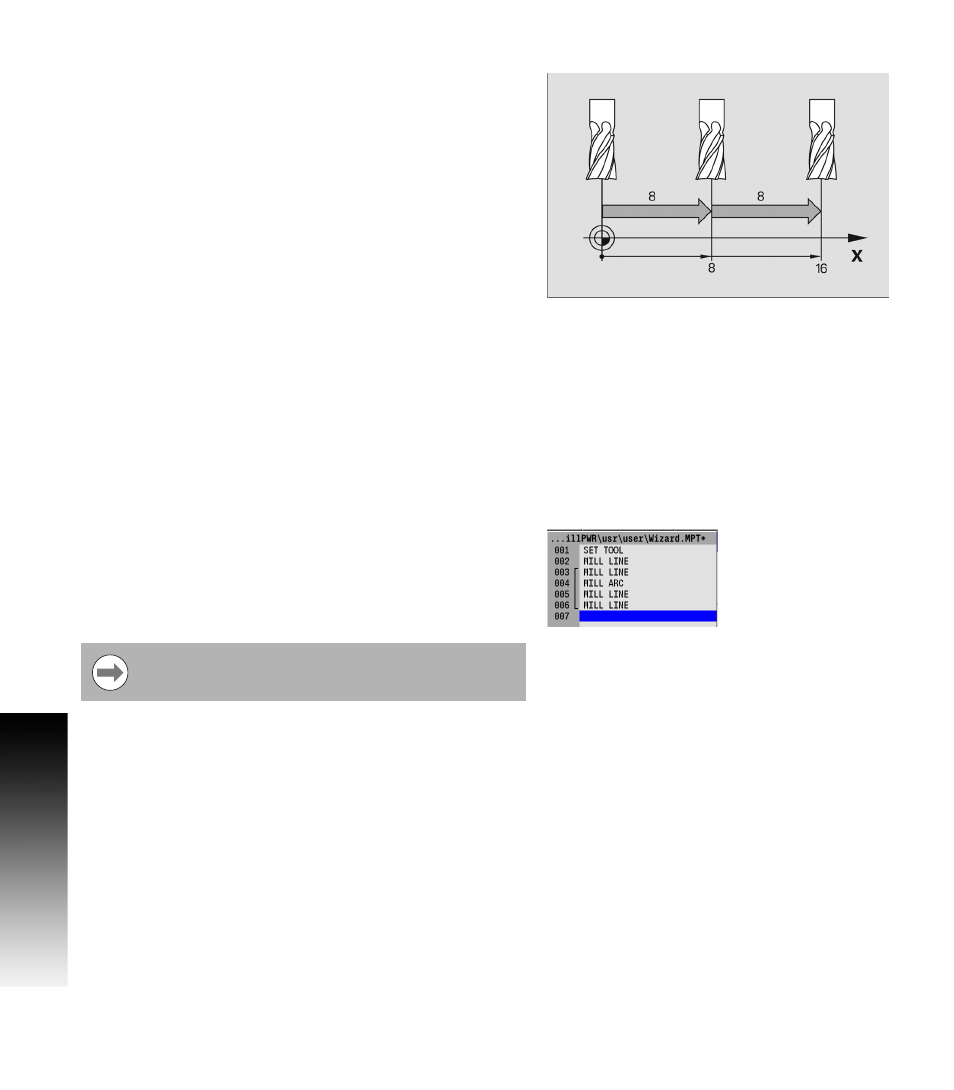

The dimension moves of 8, then 8 again are incremental moves.

The dimension moves of 8, then 16 are absolute moves.

Continuous Milling

When you program a continuous contour of lines and/or arcs the

contour will cut without stopping if there is no programmed stop.

MILLPWR

G2

will automatically recognize continuous contours as

you're programming. There are no special key presses or other

functions to learn.

For lines and arcs to be continuous, they must:

Be consecutive steps in a program.

Have the same depth.

Be cut with the same tool.

Be cut using the same tool offset.

Share a common “From” or “To” point (one step must end at the

point where the next one begins).

If one step follows another, then MILLPWR

G2

assumes that they are

to be connected (see steps 003 through 006). The single line bracket

indicates the steps that will be machined with continuous milling.

MILLPWR

G2

automatically fills in the FROM point, DEPTH, and TOOL

OFFSET from the previous step. The TO point must be filled in, and

then press the USE key.

Different feed rates within each step of a continuous

contour are allowed, and can be used.