1 millpwrg2, Acu-rite conversational, and g-code format, 1 millpwr – ACU-RITE MILLPWRG2 User Manual

Page 20

2

1 Introduction

1

.1 MILLPWR

G2

1.1 MILLPWR

G2

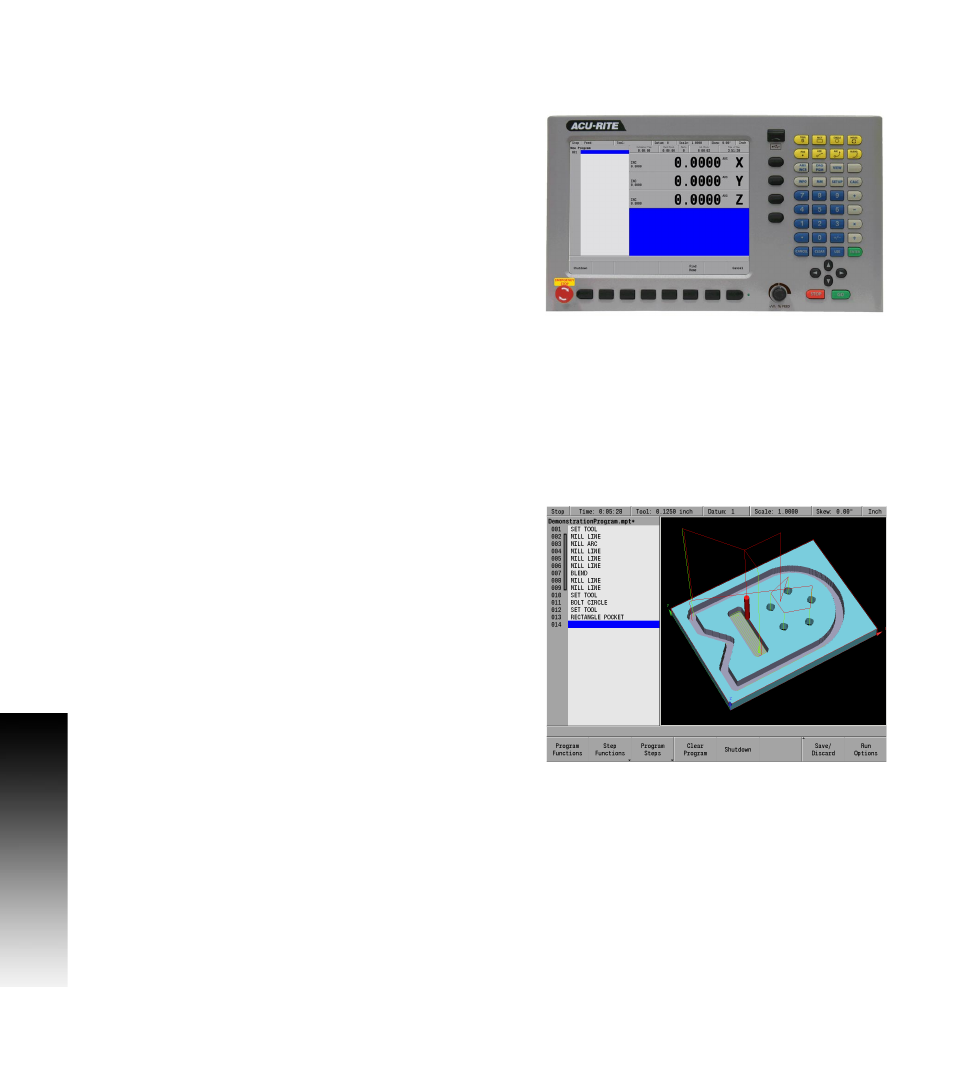

The ACU-RITE MILLPWR

G2

control is a workshop-oriented contouring

control that enables you to program conventional machining

operations right at the machine in an easy-to-use conversational

programming language. It is designed for milling and drilling machine

tools, with up to 3 axes.

MILLPWR

G2

was developed to satisfy the wants and needs of tool

and die makers and other machinists where manual and automated

operation are both useful and needed. MILLPWR

G2

will enable you to

maximize your throughput by significantly reducing set-up time, scrap,

and other non-productive operations, thereby increasing your

efficiency, productivity and profitability.

The MILLPWR

G2

has many powerful features that will improve your

productivity. The screen layout is clearly arranged in such a way that

the functions are easy to access, fast and user friendly.

MILLPWR

G2

is a closed-looped system with positioning feedback

provided by ACU-RITE precision glass scales (1µm/0.00005"

resolution). MILLPWR

G2

also includes Position-Trac™, an advanced,

unique feature that enables you to easily, quickly and accurately

re-establish work piece zero after shutting down, or power loss.

ACU-RITE conversational, and G-code format

The ACU-RITE conversational programming format is a method of

writing programs; g-code (ISO) programming can be used, and run, but

can not be edited. Preview graphics in the editor illustrate the

individual machining steps for programming the contour as well as the

corresponding tool path generated. A production drawing does not

need to be dimensioned for NC programming, the MILLPWR

G2

can be

programmed using the dimensions directly from the production

drawing. The programming format is the same as used in previous

MILLPWR products. Always verify old programs before machining

with MILLPWR

G2

.