1 milling and dr illing – ACU-RITE MILLPWRG2 User Manual

Page 148

130

8 Milling and Drilling

8.1 Milling and Dr

illing

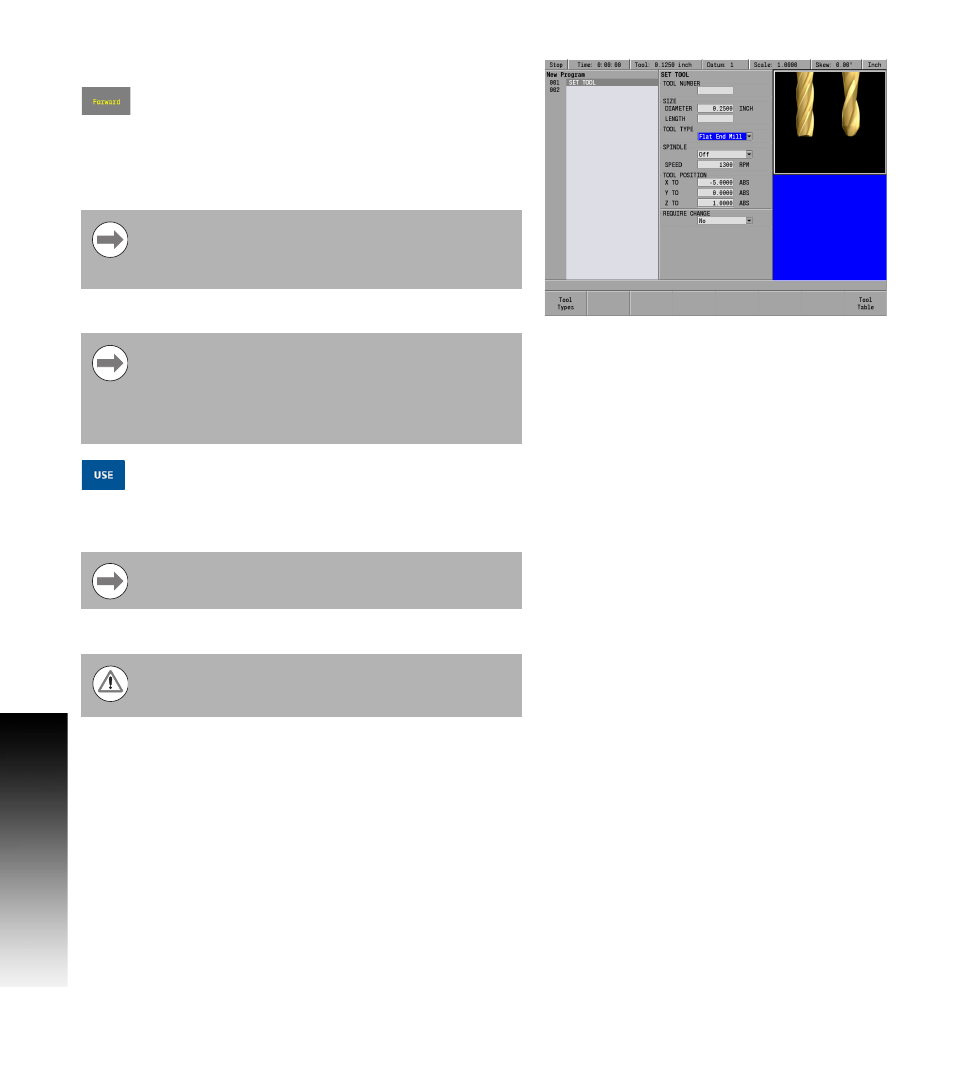

ARROW

DOWN to highlight the SPINDLE: field.

Press the Forward soft key

ARROW

DOWN to the SPEED: field (RPM) and enter the speed required

(e.g. 1300) using the numeric keypad.

ARROW

DOWN to tool position and enter the location where it is best to

make a tool change away from the part and fixtures.

ARROW

DOWN to the REQUIRED CHANGE field and select YES, or NO.

Press the USE key.

The programming of a part can now begin.

MILLPWR

G2

moves to the TOOL POSITION before

prompting the user for a tool change, making it

unnecessary to program a POSITION/DRILL step before a

tool change.

MILLPWR

G2

prompts the user to change the tool if the

SET TOOL step has a different tool than the one currently

mounted (as indicated in the status bar). If the REQUIRE

CHANGE field is set to YES, then MILLPWR

G2

will always

pause and prompt the user for a tool change (even if the

SET TOOL matches the currently mounted tool).

Tool length offsets are discussed on the following pages.

If the TOOL TABLE is used to enter a tool, MILLPWR

G2

will fill in the DIAMETER, and LENGTH fields in PGM mode

only.