Adjusting the feedrate, Preset moves, Zero incremental – ACU-RITE MILLPWRG2 User Manual

Page 46: 2 manual mac h ine p o sitioning

28

2 Machining Fundamentals

2.2 Manual Mac

h

ine P

o

sitioning

Adjusting the Feedrate

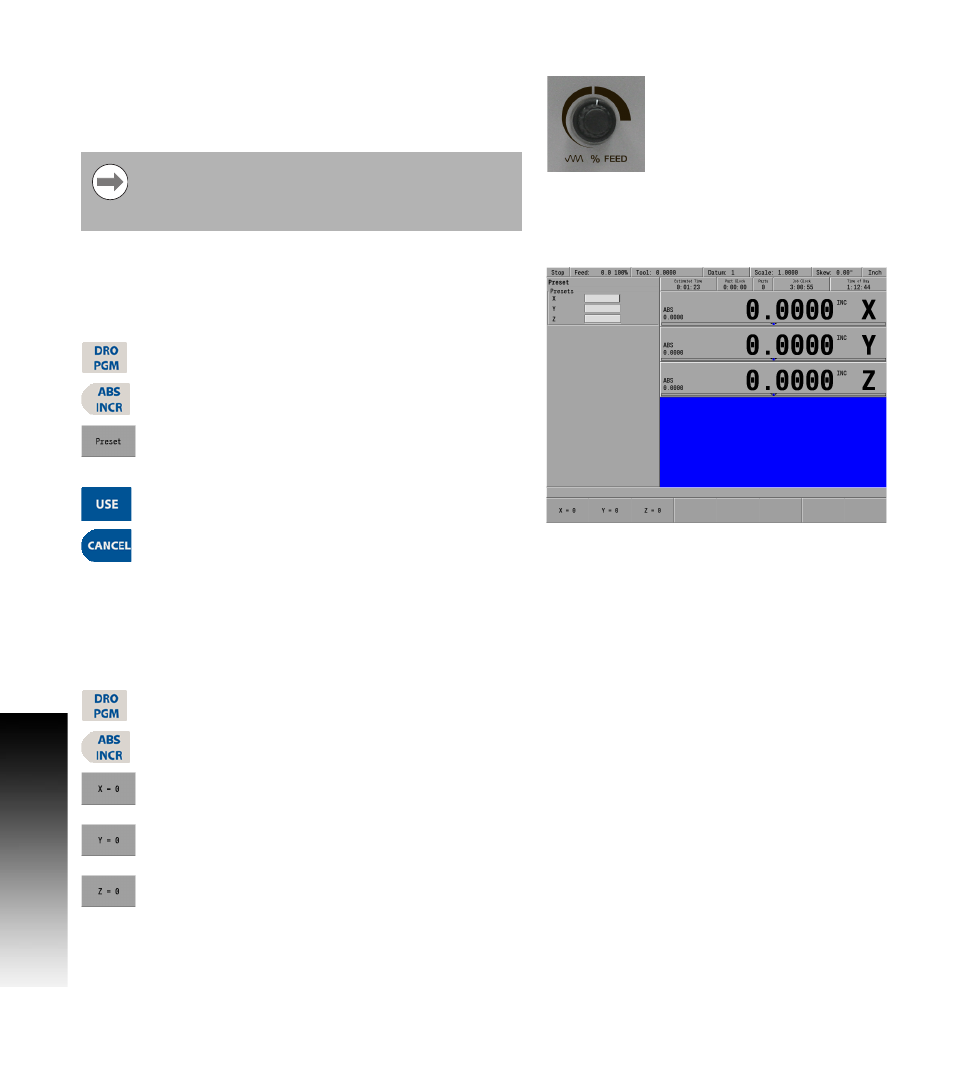

The Feedrate Override potentionmeter can be used to override the

currently active feedrate or rapid rate for machine moves. The switch

provides a range of 0% to 150%. Setting the switch to 100% will allow

the actual feedrate or rapid rate currently active to be used.

Preset Moves

The Preset feature allows the machine to be used manually like a

readout. The preset dialogue is used to set a target location. After

entering a target location, the INCR display will show the distance

between the current position to, and the target position.

Press the DRO/PGM key on the front panel to place the

MILLPWR

G2

in DRO mode.

Press the ABS/INCR key on the front panel to place the

MILLPWR

G2

to INCR.

Press the Preset soft key to open the Preset dialogue.

Enter the target coordinates for X, Y, and Z.

Press the USE key to set the target and exit the Preset

dialogue.

Press the CANCEL key at any time to cancel and exit the

Preset dialogue.

Manually move the table and/or quill until the INCR axis positions are

zero. When the INCR positions are zero, the machine is at the target

position.

Zero Incremental

The INCR display may be set to zero at the machines current location.

Press the DRO/PGM key on the front panel to place the

MILLPWR

G2

in DRO mode.

Press the ABS/INCR key on the front panel to place the

MILLPWR

G2

to INCR.

Press the X=0 soft key to zero the X axis.

Press the Y=0 soft key to zero the Y axis.

Press the Z=0 soft key to zero the Z axis.

The INCR display will show zero. As the table or quill are moved, the

INCR

display will show the distance from the current position to the

zero location.

The machine builder determines the default rapid rate and

maximum feedrate at setup. If the MILLPWR

G2

is shut

down, the configuration file reloads these default rates at

the next power up.