Tool offset, Datum selection, Tool offset datum selection – ACU-RITE MILLPWRG2 User Manual

Page 91: 1 con v ersational pr ogr a mming

ACU-RITE MILLPWR

G2

73

6.1 Con

v

ersational Pr

ogr

a

mming

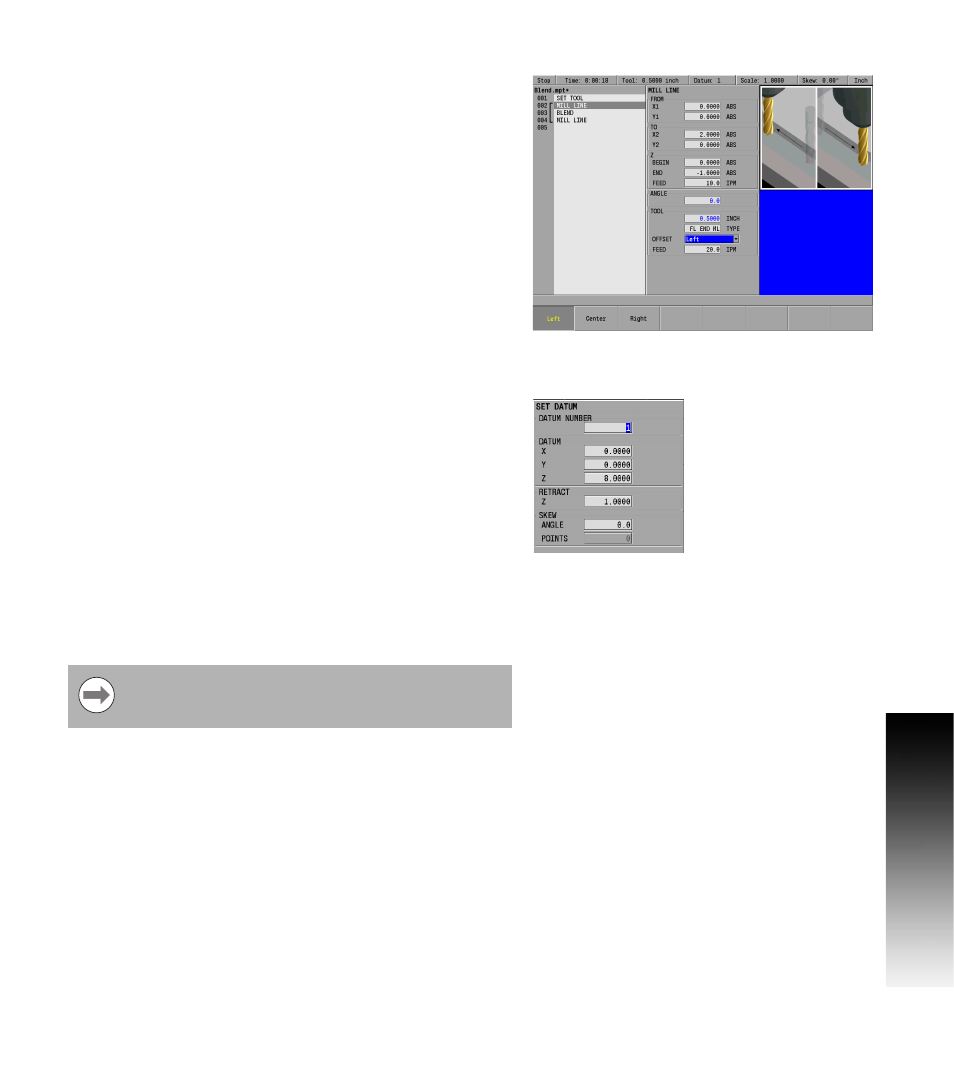

Tool Offset

MILLPWR

G2

will calculate the actual tool path when using left and

right offsets. Program the dimensions of the part as identified by the

part drawing.

Program a line, arc, frame, etc. using the “Tool Offset” field to tell

MILLPWR

G2

which side of the line the tool is to be on. See "Tool

To determine which offset to use: If the tool needs to be on the left

side of the line, use a LEFT offset. If the tool needs to be on the right

side of the line, use a RIGHT offset.

When using a CENTER offset, the programmed dimensions are for the

center of the tool. For some milling functions, like frame and arc,

INSIDE and OUTSIDE offsets are available to make it easier to define

the tool offset.

Datum Selection

The datum is where workpiece (absolute) zero is located. See "Steps

to Establish the datum" on page 81.

If the datum isn't defined on your print, then determine the datum

based upon where most of the dimensions originate.

Pick a point which will let you enter most of the dimensions directly,

with fewest calculations.

Establishing a datum requires that the Z retract position be provided

(the position the quill returns to between program steps).

By setting a retract position, you can ensure that the tool you are

using does not make contact with your workpiece when the quill

moves from one position to the next.

Establish a retract position for the Z axis each time the console is

powered, otherwise the MILLPWR

G2

will use the quill’s previous

retract position.

A two axes system also requires the Z depth, and Z retract

position. The operator will be prompted to manually move

to a depth, or retract position.