Job setup, 1 set u p – ACU-RITE MILLPWRG2 User Manual

Page 195

ACU-RITE MILLPWR

G2

177

9.1 Set

u

p

Job Setup

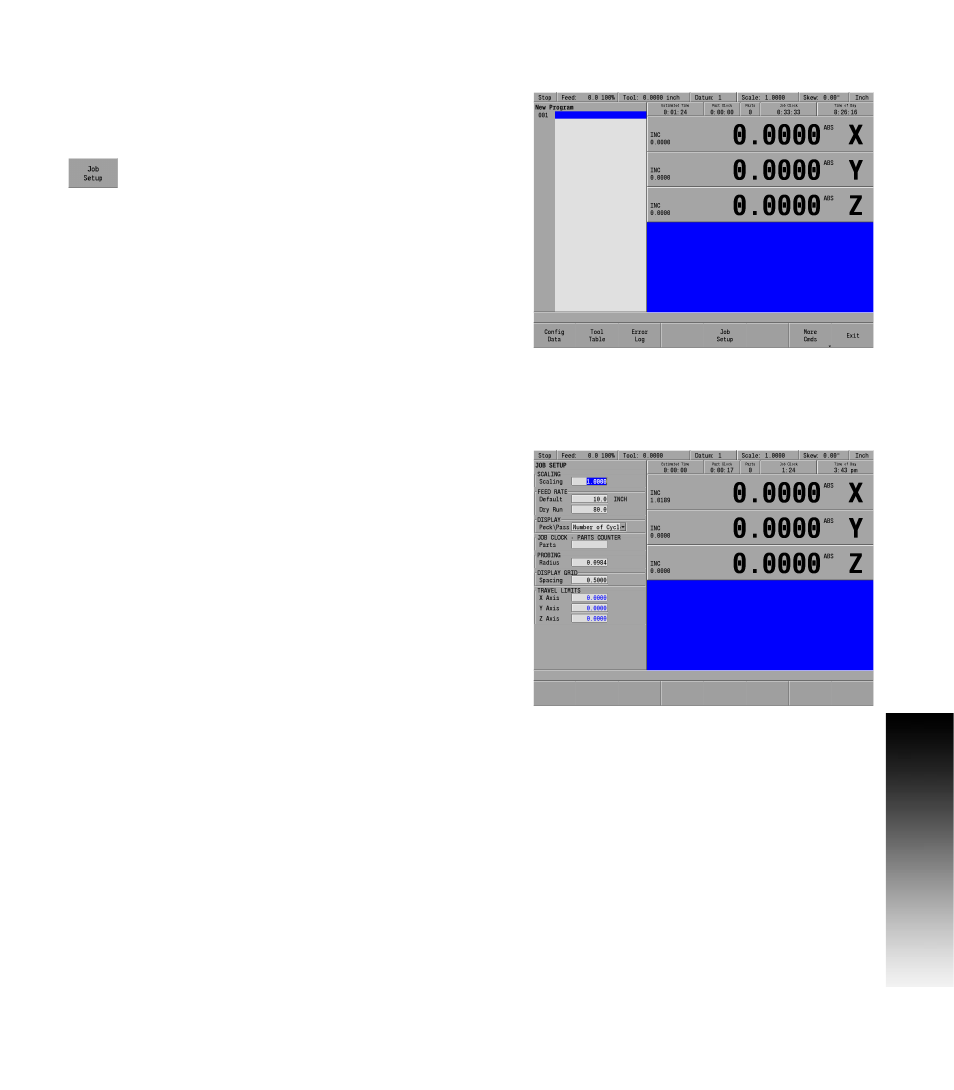

Three soft keys: Job Setup, Tool Table, and Error Log are used to

setup the MILLPWR

G2

for operation, programing, and DRO mode.

Job Setup

Press the Job Setup soft key to access the Job setup

parameters.

In the JOB SETUP dialogue there are four parameters that can be set

which the MILLPWR

G2

will default to when not overridden by another

setting.

SCALING: Typically most jobs are scaled at 1 to 1 (full scale).

Occasionally a job may be scaled down to as an example 1/2 scale.

In such a case, before programming the job, the scale factor should

be changed here so that it becomes the default scale factor for the

program.

FEED RATE: This is a Default setting that the MILLPWR

G2

will use

as well. Though this setting can change per job, and material used.

The MILLPWR

G2

will use this as the default in a program unless it

is changed (e.g. by a step that is in the program), then that new feed

rate will be used until changed again.

DISPLAY: For Peck\Pass, the setting can either be in Distance, or

Number Of Cycles. The selected option will be the default for the

dialogues and can only be changed here in Job Setup.

JOB CLOCK - PARTS COUNTER: For setting the parts counter and

stopping or starting the Job Clock. The Job Clock will provide an

estimate of time to machine the part, provide a stop watch, parts

counter, and overall Job time.

PROBING: When a probe is used, the probe tip radius is entered

here. This value will be used in dialogues where applicable.

DISPLAY GRID: When viewing a part graphic, a grid can be turned

on as an overlay to the part graphic. The grid spacing is set using

this field, and is relative to the actual part size.

TRAVEL LIMITS: The X, Y, and Z travel limits are set in the TRAVEL

LIMITS fields for each axis. Travel limits can be set at any location

that does not exceed the actual travel of the machine.