Production workflows, Printing using imposition, Imposition overview – Konica Minolta bizhub PRESS C7000 User Manual

Page 87: Imposition methods

8

Production workflows

Printing using imposition

Imposition overview

Imposition is the process of positioning page images on a sheet of

paper so that when a printer or digital printing press prints the

sheet, the page images will be in the right order. It is part of the

process of producing finished documents.

In addition to page images, you can add various marks to the

sheets to aid the production process. These marks show where the

paper should be folded or trimmed.

Imposition does not affect the content of the individual page but

rather affects only the placement of the page images on the press

sheet. Imposition is a combination of content and layout. The

content consists of the pages that should be printed, and the layout

is the location of the page on the sheet, along with the page’s

printing marks, crop marks, and fold marks.

See also:

Imposition tab in the job parameters window

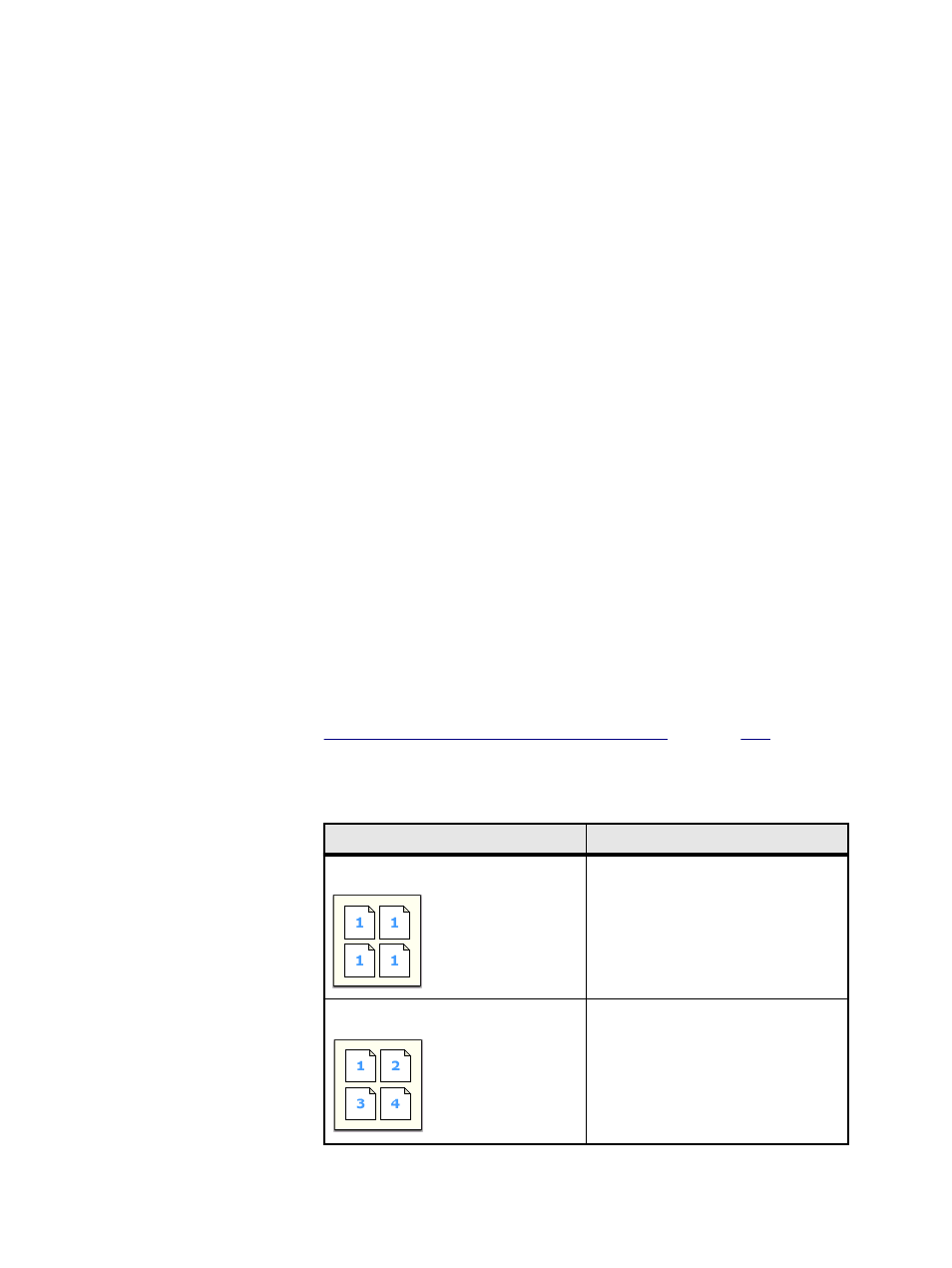

Imposition methods

The IC-307 print controller provides several imposition methods.

Imposition method

Description

Step and repeat

This method is the most efficient one

when you want to print multiple

copies of the same image and fill

each sheet to capacity—for

example, many business cards on

one sheet.

Step and continue

This method enables you to place

different pages of a job on one sheet

so that the sheet is filled to capacity.