Prt parameters – Campbell Scientific CR9000X Measurement and Control System User Manual

Page 315

Section 8. Processing and Math Instructions

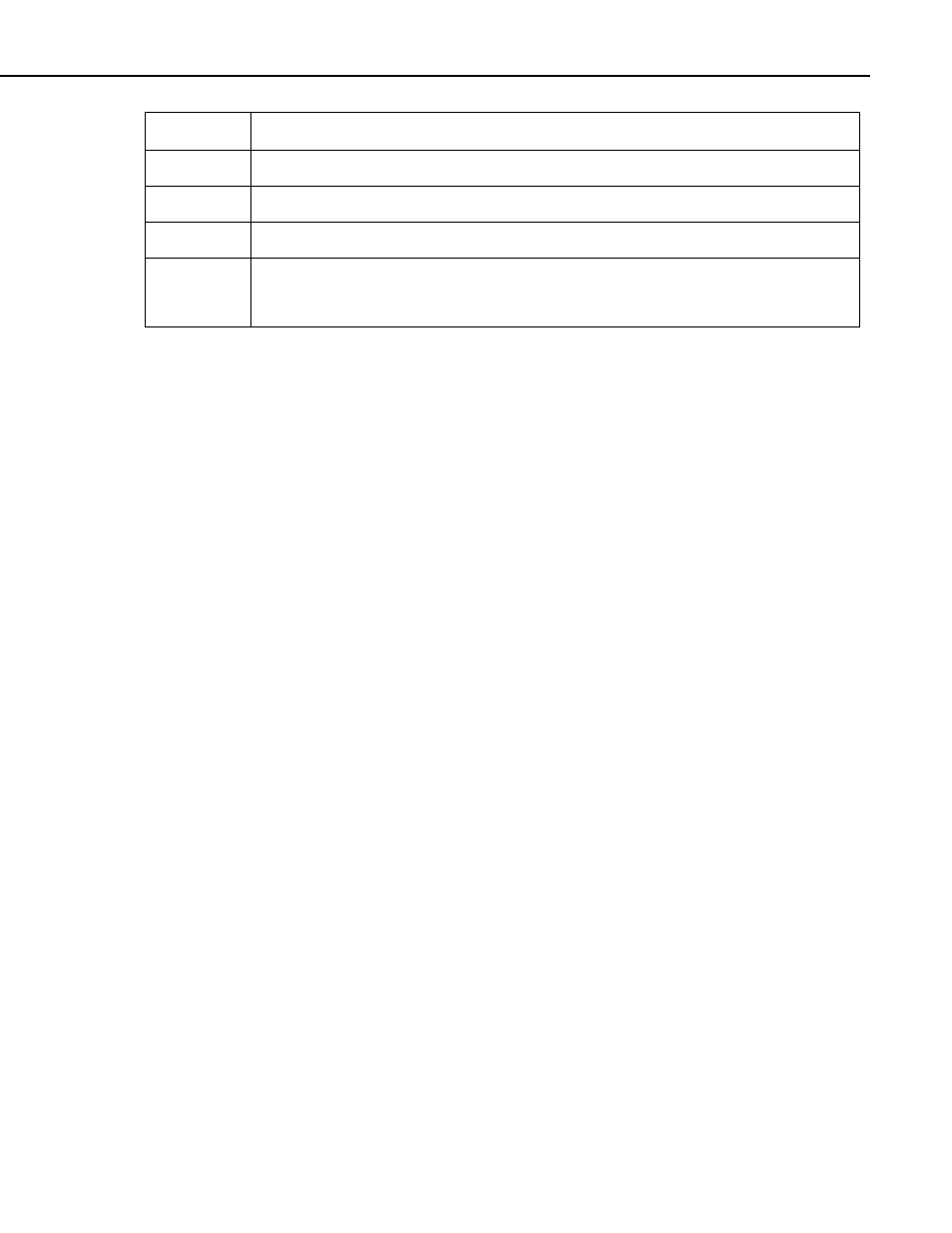

Parameter

& Data Type

Enter

PRT PARAMETERS

Dest

Var. or Array

The variable in which to store the temperature in degrees C.

Reps

Constant

The number of repetitions for the measurement or instruction.

Source

Var. or Array

The name of the Variable that is the input for the instruction. Must be the ratio R

S

/R

0

, where R

S

is the

RTD resistance and R

0

the resistance of the RTD at 0

° C.

Mult, Offset

Constant, Var.,

Array, or

Expression

A multiplier and offset by which to scale the raw results of the measurement. See the measurement

description for the units of the raw result; a multiplier of one and an offset of 0 are necessary to output in

the raw units. For example, the TCDiff instruction measures a thermocouple and outputs temperature in

degrees C. A multiplier of 1.8 and an offset of 32 will convert the temperature to degrees F.

PRTCalc (Dest, Reps, Source, PRTType, Mult, Offset)

The PRTCalc instruction is used to calculate temperature from the resistance of an

RTD.

A number of different types of RTDs are supported.

Syntax

PRTCalc(Dest, Reps, Source, PRTType, Mult, Offset)

Remarks

This instruction uses the result of a previous RTD bridge measurement to

calculate the temperature in degrees Celsius.

The input (Source) must be the ratio

R

S

/R

0

, where R

S

is the RTD resistance and R

0

the resistance of the RTD at 0

° C.

A number of different sensor types are supported. The correct PRT type should

be entered into the PRTType parameter to match the standard to which the

sensor is said to conform and/or the alpha value for the sensor. The alpha value

is the fundamental measure of the change of resistance for a given temperature

change.

For industrial grade RTDs the relationship between temperature and resistance

are characterized by a formula called the Callendar-Van Dusen (CVD)

equation. The parameters for different sensor types are given in the standards or

by the manufacturers for non-standard types. Temperature is now referenced to

the ITS-90 temperature scale. PRTCalc follows the principles given in the US

ASTM E1137-04 standard for conversion back from resistance to temperature.

For the temperature range of 0 to +850 degrees Celsius a direct solution to the

CVD equation is used resulting in errors <+/-0.0005 Celsius (caused by

rounding errors in the datalogger math). For the range of -200 to 0 Celsius a 4th

order polynomial is used to convert from resistance to temperature resulting in

errors of <+/-0.003 Celsius.

Note these errors are only the errors in approximating the relationships between

temperature and resistance given in the relevant standards. The CVD equations

and the tables published from them are in reality an approximation to the true

linearity of an RTD, but are deemed adequate for industrial use. Errors in that

approximation can be several hundredths of a degrees Celsius at different points

in the temperature range and will vary from sensor to sensor. In addition

individual sensors have errors relative to the standard, which can be up to +/-0.3

Celsius at 0 Celsius with increasing error as the temperature moves away from 0

Celsius, depending on the grade of sensor.

8-29