Saving and restoring user settings, Module limit, Inputs – Watlow EZ-ZONE RM Limit Module Rev C User Manual

Page 82: Calibration offset, Calibration

Watlow EZ-ZONE

®

RML Module

•

79

•

Chapter 6 Features

Saving and Restoring User Settings

Recording setup and operations parameter settings

for future reference is very important. If you uninten-

tionally change these, you will need to program the

correct settings back into the controller to return the

equipment to operational condition.

After you program the controller and verify prop-

er operation, use User Save Set [USr;S] (Setup Page,

Global Menu) to save the settings into either of two

files in a special section of memory. If the settings in

the controller are altered and you want to return the

controller to the saved values, use User Restore Set

[USr;r]

(Setup Page, Global Menu) to recall one of

the saved settings.

A digital input or the Function Key can also be

configured to restore parameters.

Note:

Only perform the above procedure when you are

sure that all the correct settings are programmed

into the controller. Saving the settings overwrites

any previously saved collection of settings.

Be sure to document all the controller settings.

Module Limit

This feature allows the user to setup a single output

to reflect an energized (safe) or deenergized (tripped)

state for the module. The reference to an energized

or deenergized state refers to the internal coil that

drives the Form A relay. When energized (safe) the

contact is closed, when deenergized the contact is

open. If any configured limit is tripped (process value

exceeds set point or limit input has malfunctioned),

the output LED assigned to serve as this function

will come on. By default (factory settings), output 8 is

assigned this function where any output of choice can

be configured as such.

Note:

If limit loops exist on the module that are not in-

tended to be used immediately, the loop must be

setup to avoid a trip condition. To do this simply

jumper the input for the unused loops and then en-

sure that the set point will never be exceeded (Op-

erations Page, Limit Menu) by the process variable.

Inputs

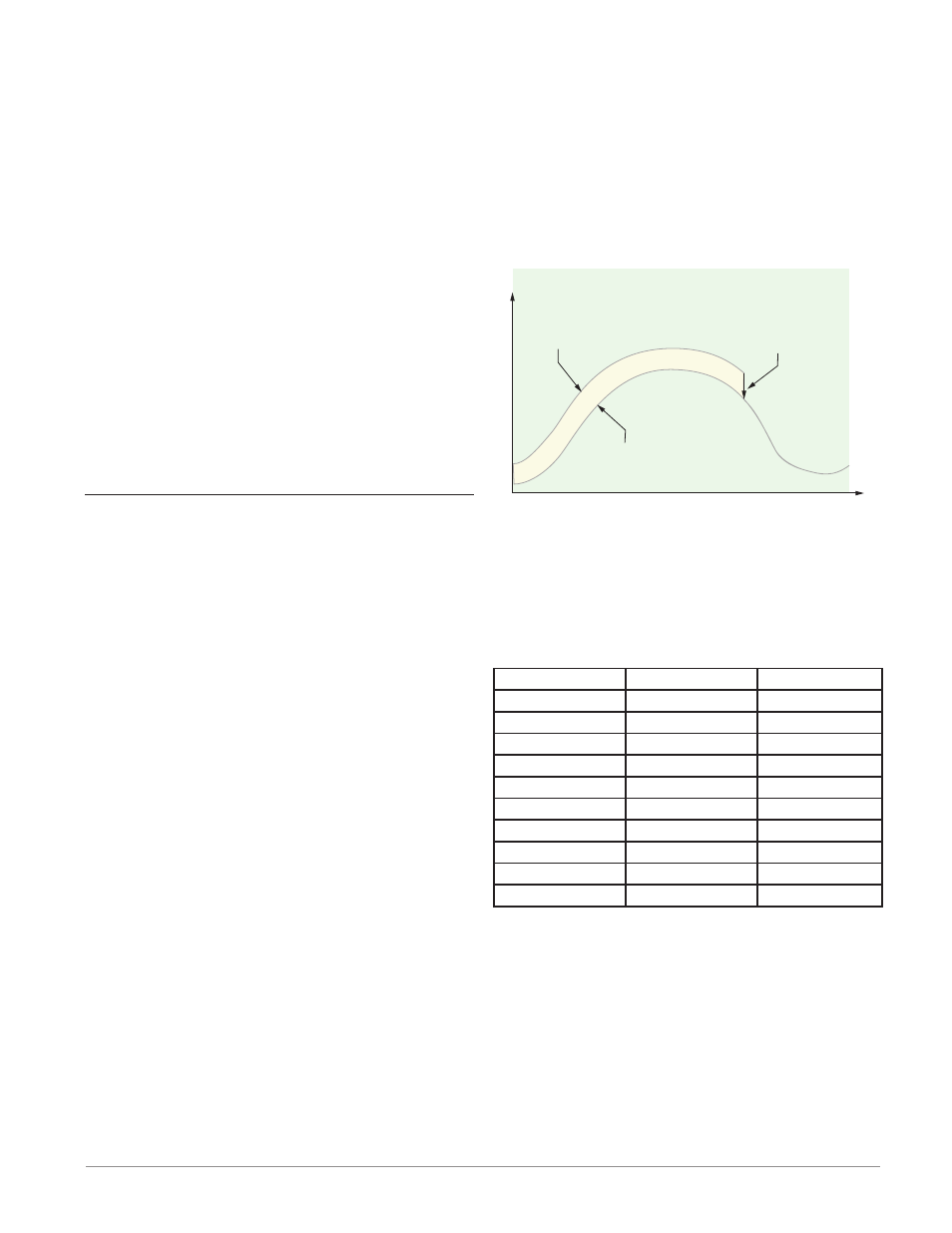

Calibration Offset

Calibration offset allows a device to compensate for

an inaccurate sensor, lead resistance or other factors

that affect the input value. A positive offset increases

the input value, and a negative offset decreases the

input value.

The input offset value can be viewed or changed

with Calibration Offset [`i;CA] (Operations Page,

Analog Input Menu).

Time

Temperature

Temperature Reading

from Sensor

Actual Process Temperature

Negative Calibration Offset will

compensate for the difference

between the Sensor Reading and

the Actual Temperature

Calibration

To calibrate an analog input, you will need to provide

two electrical signals or resistance loads near the ex-

tremes of the range that the application is likely to

utilize. See recommended values below:

Sensor Type

Low Source

High Source

thermocouple

0.000 mV

50.000 mV

millivolts

0.000 mV

50.000 mV

volts

0.000V

10.000V

milliamps

0.000 mA

20.000 mA

100 Ω RTD

50.00 Ω

350.00 Ω

1,000 Ω RTD

500.00 Ω

3,500.00 Ω

Thermistor 5K

50.00 Ω

5000.00 Ω

Thermistor 10K

50.00 Ω

10000.00 Ω

Thermistor 20K

50.00 Ω

20000.00 Ω

Thermistor 40K

50.00 Ω

40000.00 Ω

Follow these steps for a thermocouple or pro-

cess input:

1. Apply the low source signal to the input you are

calibrating. Measure the signal to ensure it is ac-

curate.

2. Read the value of Electrical Measurement [`Mu]

(Factory Page, Calibration Menu) for that input.

3. Calculate the offset value by subtracting this val-

ue from the low source signal.

4. Set Electrical Input Offset [ELi;o] (Factory Page,

Calibration Menu) for this input to the offset val-

ue.