3 assignment for each axis – IAI America RCM-GW-PR User Manual

Page 66

60

PfofiBus Gateway

5.3.3 Assignment for Each

Axis

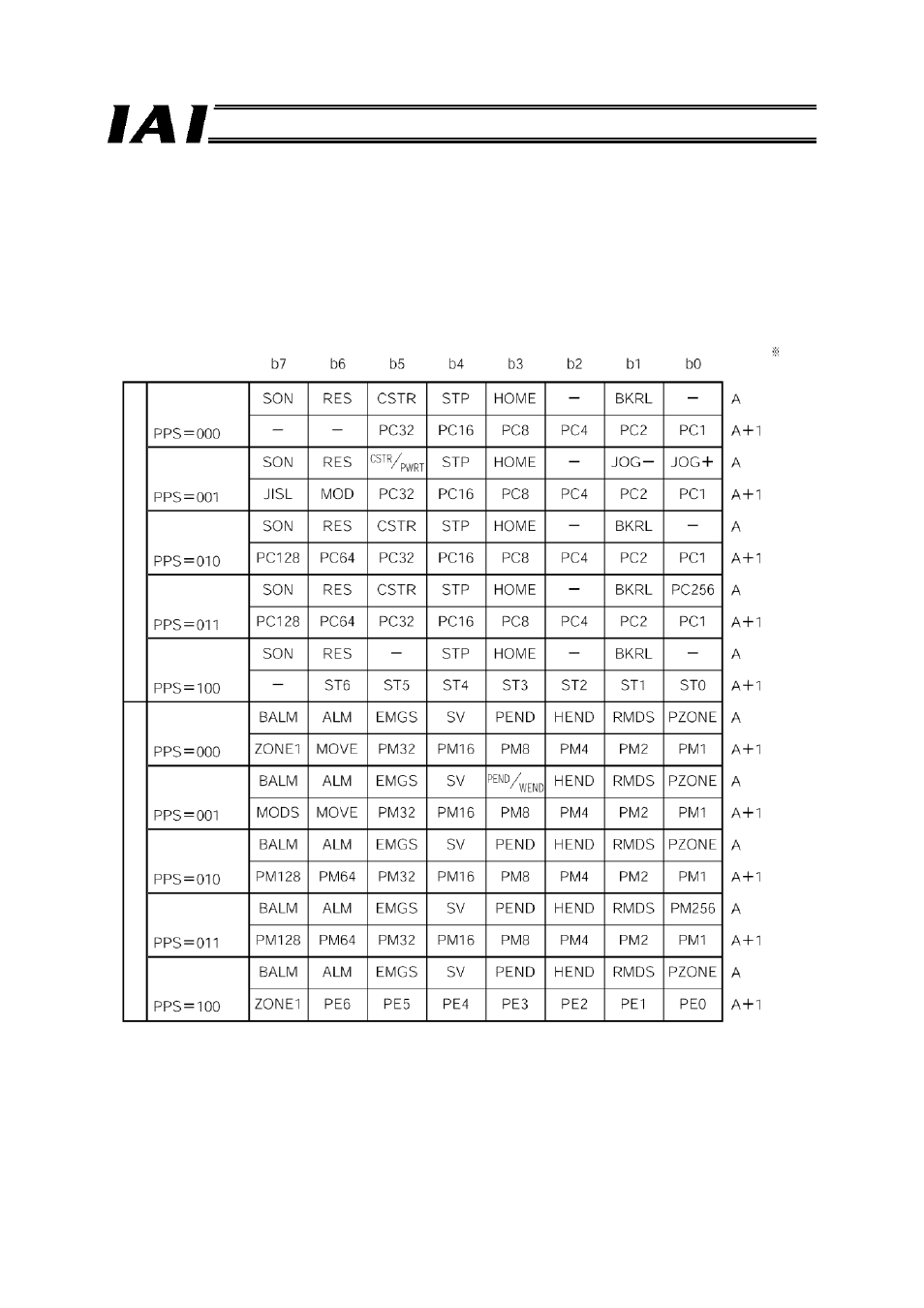

The I/O signals of each axis vary in terms of the size and content of each applicable area depending

on whether the axis is a positioner operation axis or simple direct operation axis.

(1) Control/status signals for positioner operation axis

Each axis consists of two PLC output (control signal) bytes and two PLC input (status signal) bytes,

as shown below. Five patterns are available depending on the PIO pattern set by the gateway control

signal PPS.

* Byte address A: Gateway head address + 18 + 2n

n: Axis number assigned to a positioner operation axis (0 or greater)

Byte address

PLC output

PLC inpu

t

Pattern 0

(standard mode)

Pattern 1

(teaching mode)

Pattern 2

(256 positioning

points)

Pattern 3

(512 positioning

points)

Pattern 4

(solenoid mode

1)

Pattern 0

(standard mode)

Pattern 1

(teaching mode)

Pattern 2

(256 positioning

points)

Pattern 3

(512 positioning

points)

Pattern 4

(solenoid mode

1)