Hydraulic oil installation 2 wd & 4 wd – Alamo TS-100A User Manual

Page 96

© 2005 Alamo Group Inc.

Section 10 - 2

New Holland (NH TS-100A, 115A, 125A, 135A Asy. Man) 01/05

Figure 3

Figure 2

Hydraulic Oil Installation 2 WD & 4 WD

Hydraulic Tank Filling:

1.

Filling With Recommended Hydraulic Oil. The oil

used MUST MEET the requirements as to type and

cleanliness level, THIS IS A MUST. The oil must be type

ISO Grade Hydraulic Oil w/ protection wear grade

based on abient temperature (See Decal Figure 4).

The grade of oil will vary with the ambient twmperature.

The Fluid Cleanliness level MUST BE ISO 16/14/11

rating. MAKE CERTAIN that the oil you are using meets

this requirement. If Oil does not test to cleanleness

reguirement, it will have to be filtered to clean it before

installing it into the maverick hydraulic system. NEVER

install or add Oil that does not meet these stadand

requirenments.

2.

Remove the Filler Cap and fill the Hydraulic

Tank, Make certain the oil is ISO AW 100 Hydraulic

Fluid with cleanliness level of ISO 16/14/11 is a must,

however do not over fill or spill oil.

3.

Check that all the hydraulic connections are

complete and tightened on the Motor Hydraulic Sys-

tem and the Cylinder Hydraulic System.

4.

Avoid hydraulic contamination by filtering the hy-

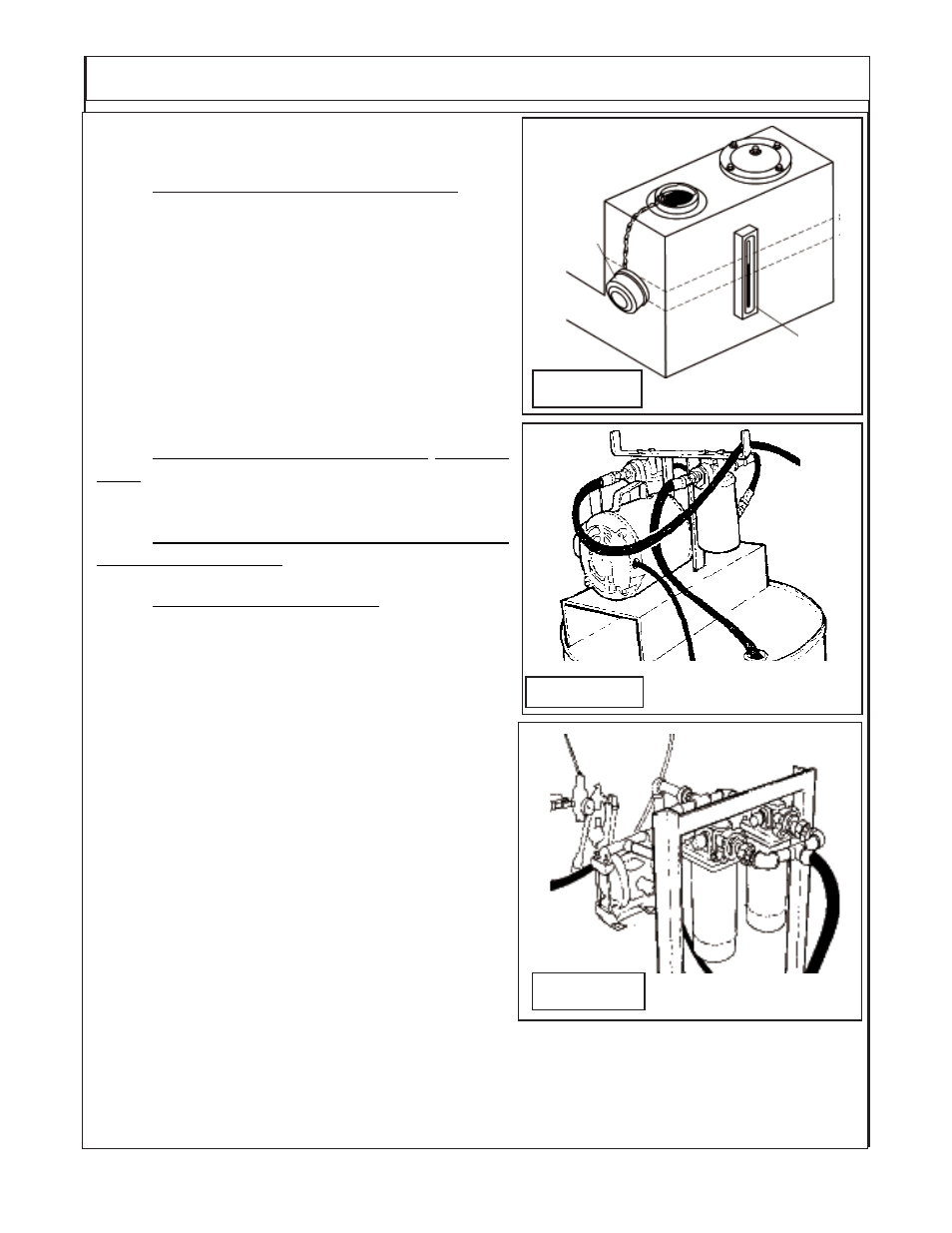

draulic oil while filling the hydraulic tank. Filter buggies

or carts are commercially available for Pre cleaning oil

before it is installed or hydraulic system cleanup. These

consist of a high-efficiency, high-capacity filter, a circu-

lating pump, a drive motor, and hoses for connecting to

oil supply. (See Figure 2 & 3)

When adding hydraulic oil, use only new oil from

a sealed barrel. Used oil or oil from an open barrel may

contain high levels of contamination. Transfer the new

oil into the hydraulic tank by using a hydraulic filter pump

unit equipped with a properly operating micron filter to

achive rquired cleanleness level is a must. This will

insure that the oil being added is safe to use. Do not just

pour the oil directly into the hydraulic tank since most

oils (even from a sealed barrel) have contaminants that

should be removed, before operating the hydraulic sys-

tem. (See Figure 2 & 3).

4.

Important: Change the return filter in tank and

suction filters at recommended hours of operation

Figure 1

1/2 Full

3/4 Full

Sight

Gauge

Fill

Cap

(See Operators Manual for maintenace schedule). The only hydraulic oil to be used is the AW

ISOAW Tractor Hydraulic Oil (See Figure 4 for oil Grade ) with a cleanliness level of ISO16/14/

11. Always use a good Filter Maintenance program and Oil cleaning system before adding any oil

to system..