Pump / drive assembly instructions, Install tank rail weldments, Installing pump mntg weldment – Alamo TS-100A User Manual

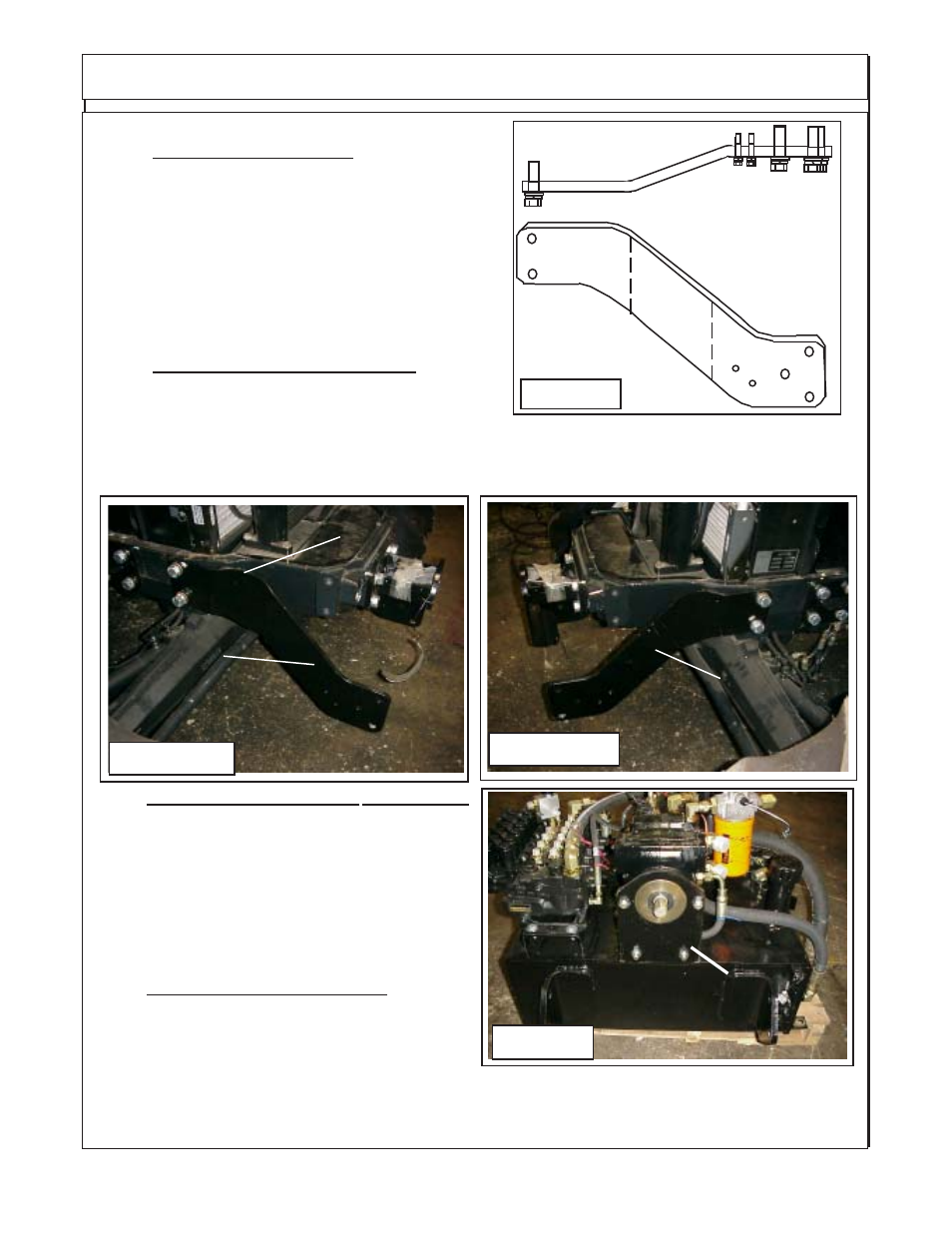

Page 28: Figure 5, Figure 6, Figure 7, Figure 8 pump shipping bracket

© 2005 Alamo Group Inc.

Section 3 - 4

Maverick (NH TS-100A,115A,125A, 135A Asy. Man) 01/05

bolts (P/N 02975959) and 20 mm lockwashers (P/N 02971158) . Install the Pump Mounting

Weldment (P/N 02980719) with the opening for the driveline cover up. Tighten the four mounting

bolts now. (See Figure 8)

Pump / Drive Assembly Instructions

Install Tank Rail Weldments:

1

.

Install Tank Rail Welments. P/N 02981405 LH

and P/N 02981404 RH. These will bolt on using the two

holes to the front of the frame rail supports. This will need

to be done so the hydraulic tank can be mounted.

tighten these two bolts (two each side) now. NOTE:

There is a left hand and a right hand weldment, the best

way to determine which is LH and RH is theway they fit.

The bend is bolted on to make the distance between the

two tank rails the same as the width of the hyd tank.

Installing Pump Mntg Weldment :

1.

Install Pump Mounting Weldment. The Pump

Mount Weldment (P/N 02980719) bolts to the front

of the tractor bolster using four 20 mm X 45 mm long

2.

Remove Bolt on Cover In front of After Cooler.

This is an important step. The Air Conditioner Hoses

and the Oil Cooler Hoses are under this cover (See

Figure 6 & 11). These hoses must be tied and routed

so the driveshaft will not rub them when engine is

running. The hose can be tied with a sturdy plastic

tie or other means sufficient to hold the hoses away

from driveshaft

.

3.

Remove Pump Shipping Bracket. The pump

is shipped using a bracket that bolts to the pum and

the tank assembly. Before pump can be installed it

will have to be unbolted from pump and tank. The

shipping bracket is for shipping only and will not be

Figure 5

123

123

123

123

123

123

123

123

123

123

123

123

123

123

12

12

12

12

1

1

12

12

RH Side Shown,

Tractor

Figure 6

RH Tank Rail

Bolt on Cover on

Figure 7

LH Tank Rail

Figure 8

Pump Shipping

Bracket

used. When unbolting pump from tank assembly there are hoses that will have to be disconnected from

pump as tank to pump hoses (filters are connected when assembly is shipped. Caution must be taken

when disconnecting these fittings and/or hoses to keep the capped to keep contamination out of them.