Frame installation – Alamo TS-100A User Manual

Page 54

© 2005 Alamo Group Inc.

Section 5 - 14

Maverick (NH TS-100A,115A ,125A,135A Asy. Man) 01/05

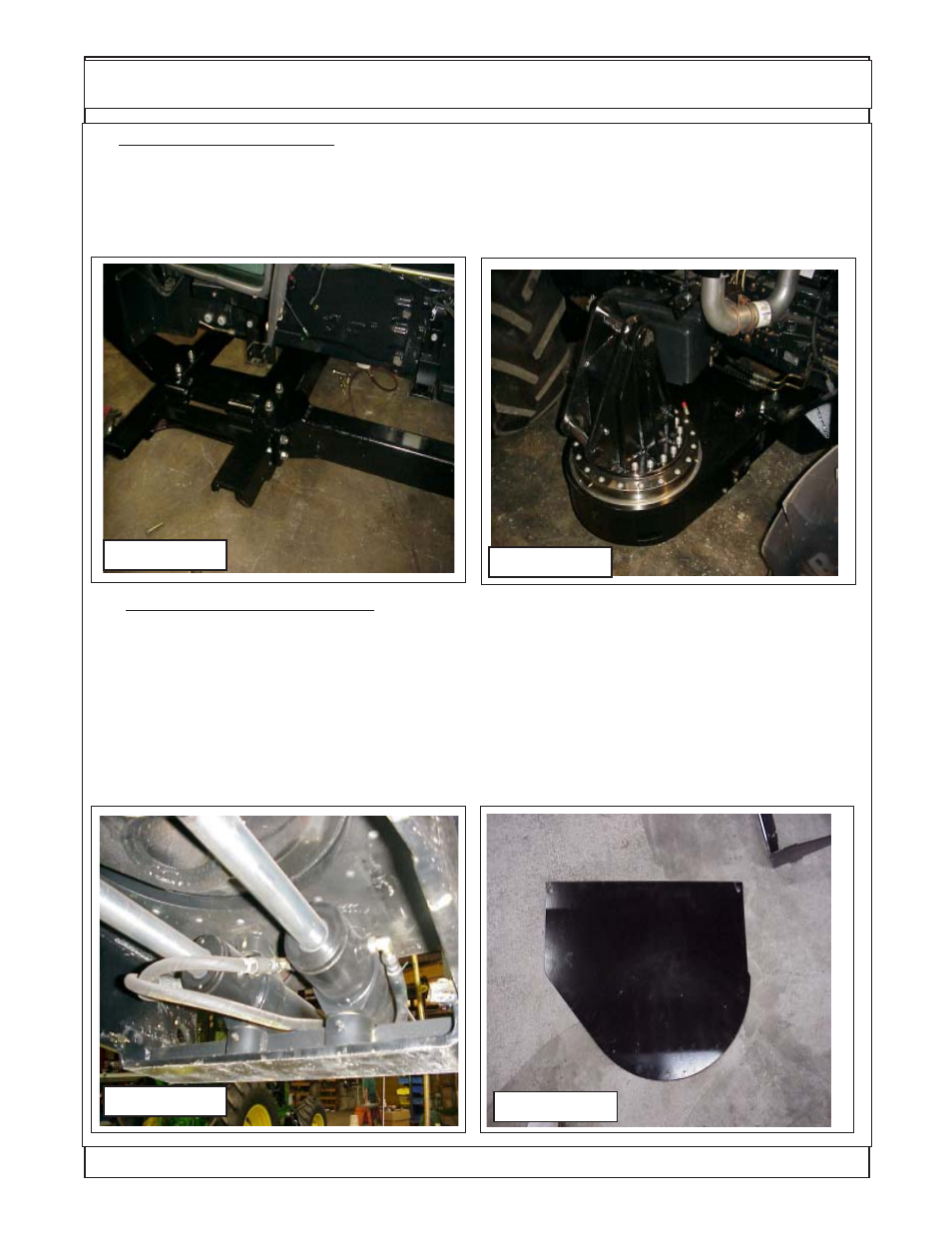

Figure 37

Figure 38

3.

Turret Assembly Installation. Theturret assembly mounts on the RH side onto the center section

under frame (See Figure 36 & 37) . Using a hoist (or other lifting device) lower the turret assembly until

it is level with the underframe. Slide the turret assembly inward toward the under frame until the retaining

pin tube on under frame an turret assembly align. Installthe long upper retaining pin and then the two small

front and rear pins. The long upper pin is retained with two cotter pins that need to be bent over on the

ends. The short pins are retained with nuts and bolts (See Figure 36 & 38).

Frame Installation

4.

Turret Assembly Grease Fittings. The turret assembly has three grease fittings around the OD of

it. The grease fittings are 120° apart, this is to make certain that the bearing will be greased all the way

around because of the large diameter of the bearing. This bearing must be greased before unit is put into

service. It is easier to get to grease fittings now than after boom has been installed. On the under side

of the turret assembly are the grease fittings for the swing cylinder pivot mounts, these need to be

greased before operating the unit. Also there is a bolt on cover on the under side of turret that will be

installed (See Figure 40) at a later time. Greasing the cylinder pivots will need to be done before the cover

is installed (See Figure 39) and the boom swing stop will need to be adjusted, but this cannot be done

until a later time making it best to leave this cover of until then. After greasing components at assembly

of unit operator should consult the operators manual for maintenance requirements.

Figure 39

Figure 40