Alamo TS-100A User Manual

Page 79

© 2005 Alamo Group Inc.

Section 8 - 15

Maverick (NH TS-100A,115A, 125A, 135A Asy. Man) 01/05

Maverick Sensor Connections

:

1.

Instrumentation The Maverick Boom utilizes

instrumentation for certain decision making activi-

ties. Listed below are the sensors included on this

unit. Tank Temperature Sensor, Charge Pressure

Filter Switch, Valve Pressure Filter Switch and Re-

turn Filter Switch.

2.

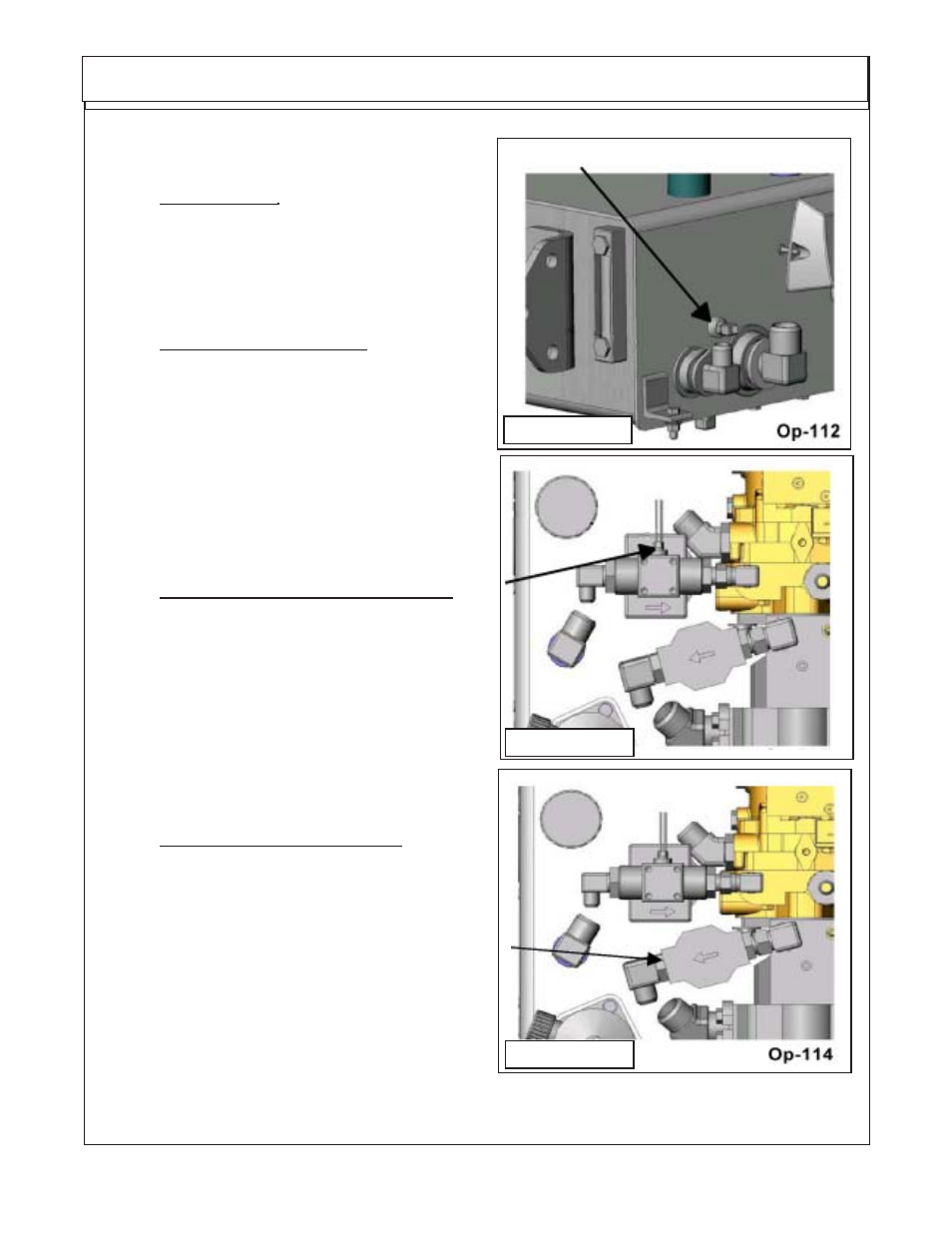

Tank Temperature Sensor. The tank tem-

perature sensor monitors the fluid temperature in

the area of the pump suction screens. the tempera-

ture is real time and is used on the network to

accomplish certain objectives. The first, is to display

on the interface while the cutter circuit is operating.

The second, is to be used to control the electric fan

on the hydraulic cooler. At any time the fluid level

reaches 150° F. the fan is activated and remains

activated until fluid temperature drops to or below

the desired temperature (See Figure 33).

3.

The Charge Pressure Filter Switch The

charge filter pressure switch has three wire coming

out of it, a white , black and Blue wire. The Blue wire

will not be used and will be cut off. The charge

pressure filter switch is located at the filter in the

charge loop on the hydrostatic pump (See Figure

34). The sensor monitors the back pressure created

by the filter element when in use. When the back

pressure reaches a setting of 50 psi the switch will

trigger and prompt the operator for a filter element

change of filter element.

4.

The Valve Pressure Filter Switch The Valve

pressure filter switch is located at the pressure filter

in the valve pressure circuit, between the closed

center load sense pump and the control valve (See

Figure 35). The sensor monitors the back pressure

created by the filter element when in use. When the

back pressure reaches a setting of 50 psi the switch

will trigger and prompt the operator for a filter

element change.

WARNING! This filter does not have a by-

pass. The element must be changed at the appropri-

ate time to avoid element damage and system

contamination.

FIGURE 33

FIGURE 34

FIGURE 35

Exterior Wire Harness Schematic P/N 02981375A