Line leak detector (lld) alarms – Franklin Fueling Systems T5 Series Fuel Management System Programming Guide User Manual

Page 60

56

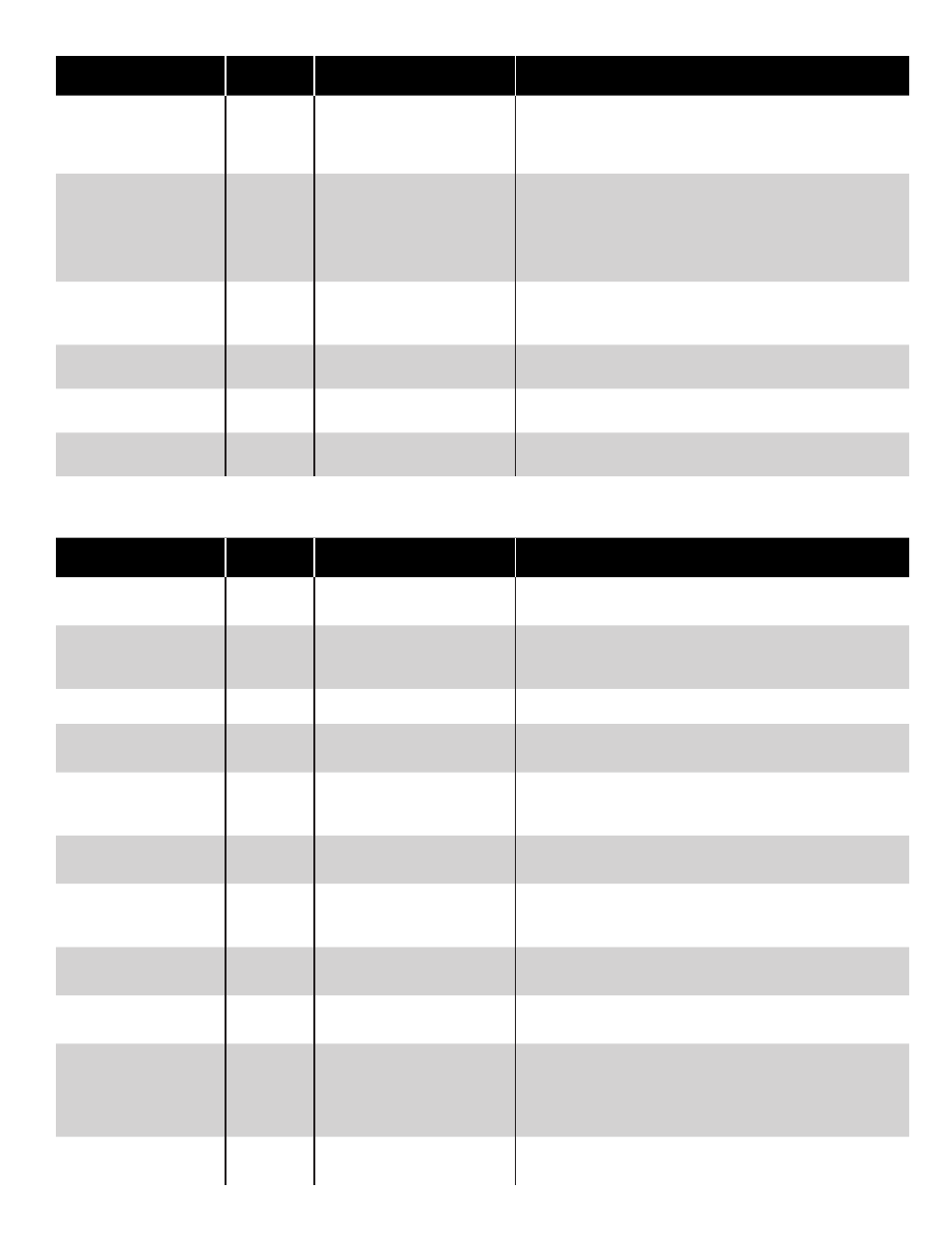

Displayed Alarm /

Warning

Device

Description

Recommended Actions

SN3 Pwr Short

Slot

3-Wire sensor malfunction.

If a 2-Wire sensor is used on a 3-wire module ensure that the

red / pwr terminal is not used. If a 3-wire sensor is used, disconnect

wires and see if alarm clears. If alarm clears inspect shorts in wiring.

If alarm stays at PWR short replace module. Contact Franklin Fueling

Systems’ Technical Services Dept. for support.

SN3 Sensor On

ChannelSN3 Discriminating sensor shows

alarm status.

Inspect location for presence of liquid. In the case of a leak, follow

site policy procedures. If no liquid is present, and alarm still exists,

sensor may be tripped on error. Check wiring continuity from sensor

to console. Test sensor at console, trip sensor on purpose. Verify

console terminal wiring. If issue still exists, inspect wiring to probe. If

the condition still exists, contact Franklin Fueling Systems’ Technical

Services for support.

SN3 Sump Full

ChannelSN3 3-wire sensor detected sump full

of liquid.

Inspect location for presence of liquid. In the case of a leak, follow

site policy procedures. If in alarm with no liquid is present, sensor

may be tripped on error. Check wiring continuity from sensor to

console.

SN3 Sync Error

ChannelSN3 3-wire sensor data signals not in

sync with module.

Verify correct wiring and re-make the connections. Verify sensor type.

SN3 Vapor

ChannelSN3 3-wire discriminate sensor

detecting vapors at location.

Visually inspect area for product presence. Verify the vapor level has

been calibrated correctly.

SN3 Water

ChannelSN3 3-wire discriminate sensor

detecting water at location.

Visually inspect area for water presence.

Line Leak Detector (LLD) Alarms

Displayed Alarm /

Warning

Device

Description

Recommended Actions

0.1 GPH Compliance

Expired

Line

A 0.1 gph test has not been

completed within the last 365

days.

Verify that no pertinent alarm conditions have been reoccurring.

Ensure that there is enough time to pass the test.

0.2 GPH Compliance

Expired

Line

A 0.2 gph test has not been

completed within the last 30 days.

Verify that no pertinent alarm conditions have been reoccurring.

Ensure proper seating pressure. If Firmware revision is older

than 1.7.4.5535, upgrade to make use of the Statistical Line Leak

Detection enhancement.

3 GPH Compliance

Expired

Line

The required daily 3 GPH test has

not been completed.

Check for continuous pump on conditions that could be caused by a

sticky handle switch or relay.

Air in Line

Line

Air has been detected in the line.

Purge all air from the line starting at the furthest dispenser and

working in toward the STP. Verify tightness of lines and investigate

other sources for air infiltration.

Dispensing Pressure Test

Failed

Line

Pressure during dispensing

dropped below 7.5 psi. This is

seen as a catastrophic leak during

dispensing.

Inspect all sumps for product. Use a pressure gauge to test line

pressure during dispensing. See “LS500 Auto Learn Line Leak

Detection Installation & User’s Guide” FFS 000-2145. Contact

Franklin Fueling Systems’ Technical Services Dept. for support.

Extended Hook Signal

Line

A hook signal has been detected

for more than 60 minutes with the

line pressure staying the same.

Check for voltage to the AC-Input module. If issue still exists contact

Franklin Fueling Systems’ Technical Services Dept. for support.

Failed to Catch Pressure

Line

The pump OFF pressure has

dropped below 7 psi within

1 second after the pump was

turned off

Inspect all sumps for product. Refer to “LS500 Auto Learn Line

Leak Detection Installation & User’s Guide” FFS 000-2145 for more

information.

Failed to Pressure Up

Line

The Line has called for the pump

to turn on but did not see the

pressure increase

Inspect all sumps for product. Refer to “LS500 Auto Learn Line

Leak Detection Installation & User’s Guide” FFS 000-2145 for more

information.

Gross Leak Detected

Line

The console has detected a line

leak greater than 3 gph.

Inspect all sumps for product. Refer to “LS500 Auto Learn Line

Leak Detection Installation & User’s Guide” FFS 000-2145 for more

information.

High Pump Pressure

Line

The Pump Off pressure has

stayed above 49 psi for 3

consecutive times.

Inspect all sumps for product. Ensure that no other check valves are

used within the system. Observe multi-point line pressure readings

during pump on and off using a pressure gauge in the line. If line

pressure is high, there may be a blockage in the line. Refer to “LS500

Auto Learn Line Leak Detection Installation & User’s Guide”

FFS 000-2145 for more information.

Line is not configured

Line

Specified line is not configured,

therefore line leak test will not be

performed.

Verify line programming. If necessary configure line.