Programming fms parameters – Franklin Fueling Systems T5 Series Fuel Management System Programming Guide User Manual

Page 32

28

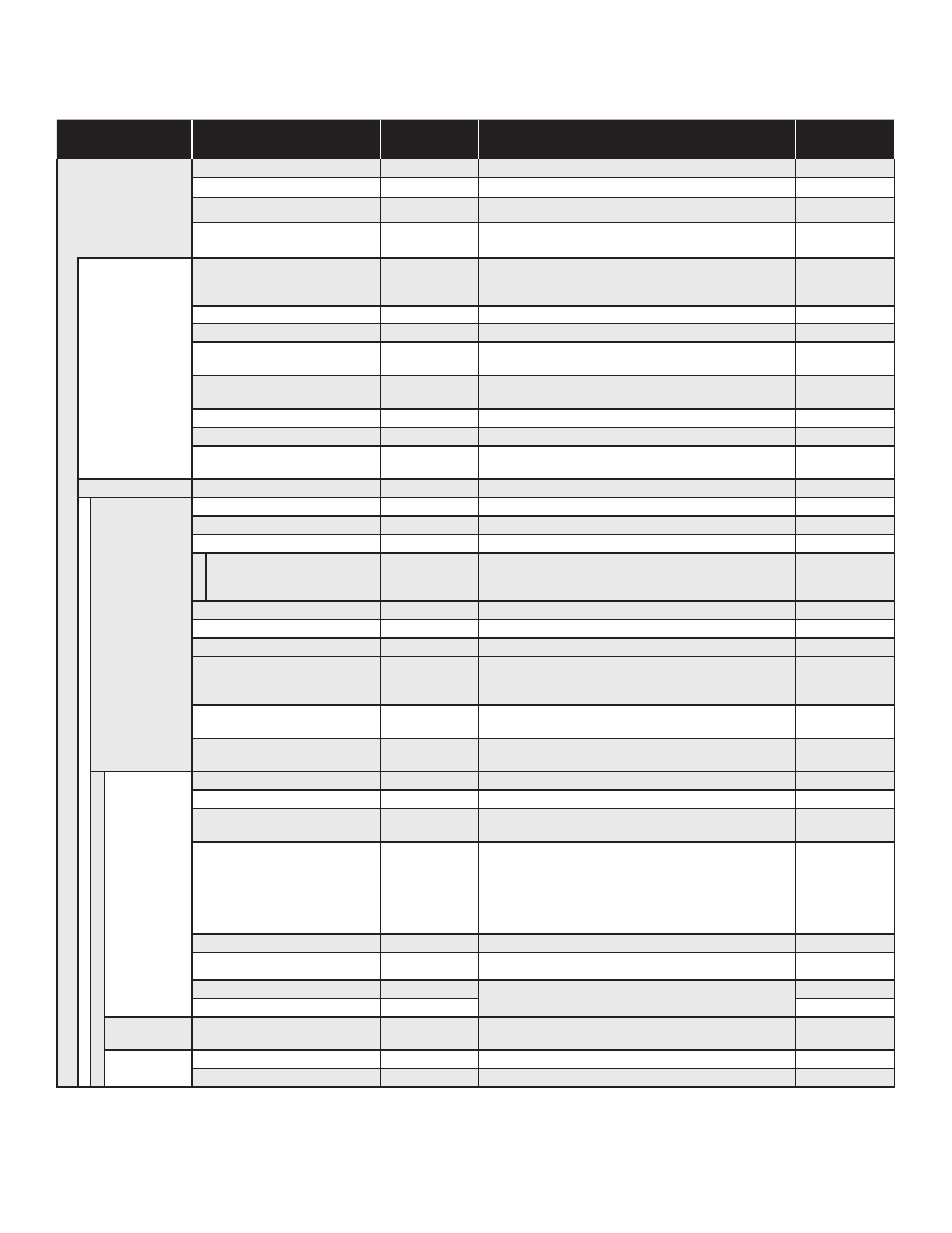

Programming FMS Parameters

Here is where specific equipment parameters will be modified to match the site setup.

Fuel Management System

Group Name

Parameter Name

Parameter

Default

Description

Parameter

Input

Fuel Management

System

Ullage Percent

(95)

Percent of tank level used to calculate space left.

70-100 %

Delivery Delay

(15 min)

Time after delivery when increase is reported.

# min.

Correction Temperature

(60.00 °F)

Product temperature correction.

# °

High Product Limit

(Level)

Select whether the High Product alarm will be triggered

by high product Level or high product Volume.

Level / Volume

Static Tank Testing

Region

(United States) The region in which the gauge is located

Other

United States

Spain

Monthly Leak Test Threshold

(0.20 gph)

Static leak tolerance for testing tanks.

# gph

Yearly Leak Test Threshold

(0.10 gph)

Static leak tolerance for testing tanks.

# gph

Sentinel Mode Threshold

(3.00 gph)

If Sentinel Mode is configured, this is the amount of

volume that would trigger an alarm.

#

Confidence

(99%)

Leak testing confidence.

90, 95, 97.5,

99 %

Minimum Leak Test Time

(2 hr)

Minimum amount of time used to test.

0-8

Maximum Leak Test Time

(8 hr)

Maximum amount of time used to test.

1-8

Alarm On Precision Leak Test

Failure

(No)

Used to produce an alarm upon failure.

Yes/No

Tanks

Number of Tanks

(0)

Number of tanks in fuel system.

0-48

Tank #

Name

(Tank 1)

Given name of tank.

abc#

Type

(Special 1)

Type of tank.

Std./Spcl.

Manifolded

(No)

Used for Manifolded tanks.

Yes / No

Manifold #

(1)

If Manifold is selected, this option will allow you to

select a manifold number. Tanks that are Manifolded

should have the same manifold number.

1 - 24

Product #

( 1)

Type of product in tank.

1-48

Delivery Threshold

(200.0 gal)

Amount of increase to report delivery.

# gal

Theft Threshold

(5.0 gal)

Amount of decrease to report theft.

# gal

4-20 mA Output

(None)

If an IO module is used and the outputs are configured,

this option will appear. Select the correct output that

correlates to this tank.

None

Output 1-4

Monthly Compliance

(Yes)

Select Yes if this tank is to appear on the Compliance

page and in the Regulatory report.

Yes / No

Annual Compliance

(Yes)

Select Yes if this tank is to appear on the Compliance

page and in the Regulatory report for annual tank testing.

Yes / No

Probe

Channel

(Probe 1)

Channel used for the probe in tank.

Probe

Type

(Standard 101) Type of probe used in this tank.

Std./Spcl.

Ratio

(1 to 1 tip to

head)

Ratio of float movement in proportion to product level.

1:7-9 for use with Moorman gauge interface.

1:1; 1:7; 1:9

Float Type

(4 in gas)

Type of float(s) used on probe.

4, 3, or 2 in.

Gas/Diesel,

Stainless,

Propane

Gas density

Diesel Density

Water Float

(Yes)

Select Yes if water float is present.

Yes /No

Gradient

(9.03000 µs / in) Speed of probe wire.

# µs/in

Product Offset

(0.00 in)

Used for compensation of tank tilt. (See Appendix xx:

Calculating Tank Tilt).

# in

Water Offset

(0.00 in)

# in

Generator

Mode

Enable

(No)

If generator testing is being used, select yes.

Yes / No

SCALD

Enable

(No)

Enables SCALD tank testing.

Yes / No

Qualify

(14 %)

Required percent full to run SCALD test.

# %