Franklin Fueling Systems T5 Series Fuel Management System Programming Guide User Manual

Page 51

47

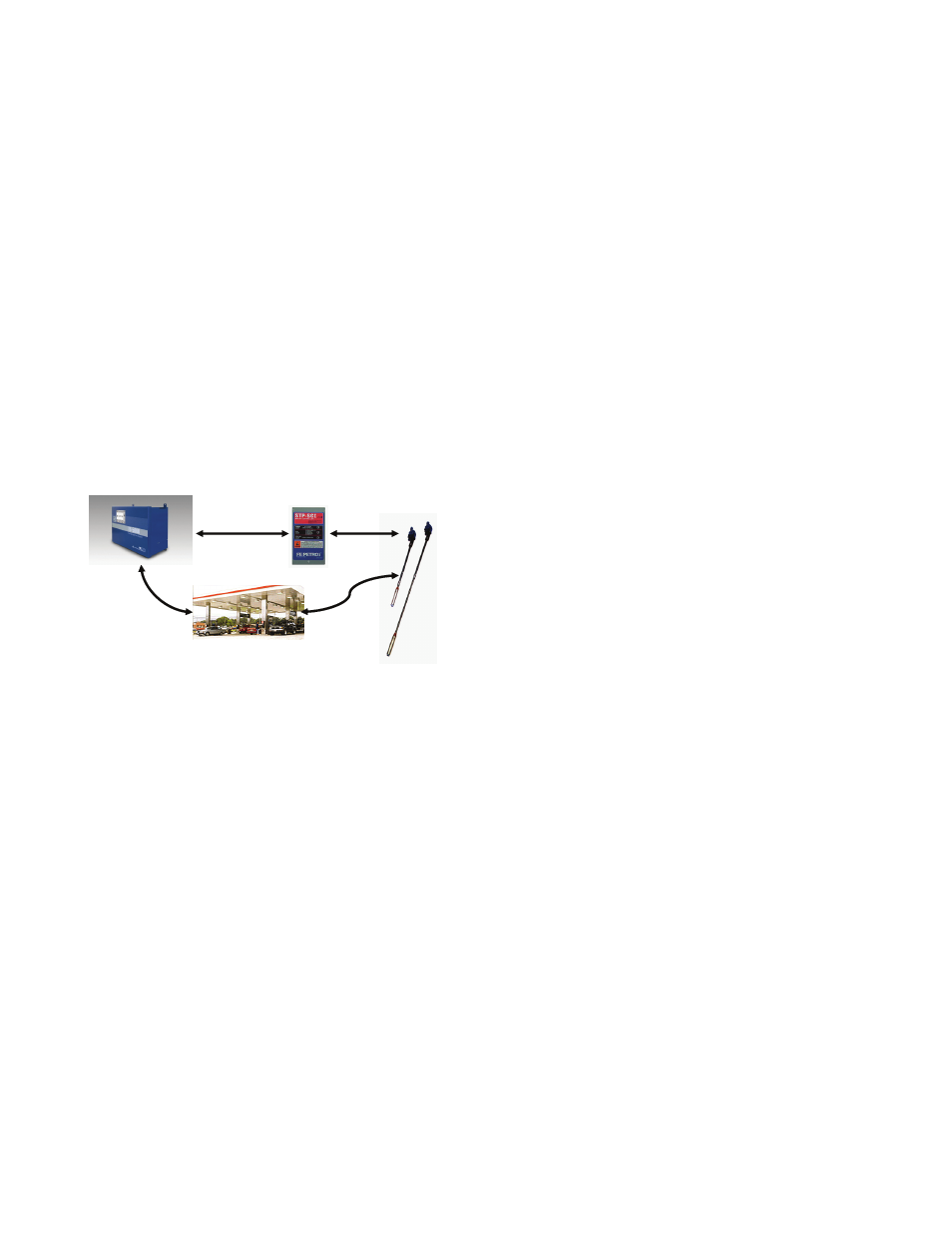

TS-TPI Overview and Functionality

Tank fuel management can be achieved using a Franklin

Fueling Systems T5 Series Fuel Management Systems

and an FE Petro

Turbine Pump Controllers (STP-SC1,

EcoVFC or MagVFC). Refer to Bulletin TB1010-04 for

connecting to an STP-SCIII controller.

Tank Fuel Management looks at percent (%) full volume of

individual tanks and gives priority to the submersible pump

needed to control tank inventories. Additional features and

benefits of the Tank Fuel Management system include:

• Tank Overfill Protection

• Dry Tank Indication

• Automatic pump controller reset

• Clogged Intake Indication

• Pump in Water Indication.

Tank Fuel Management can be used to keep tank levels

similar, eliminating the need for a syphon system. Tank

Fuel Management can also be used to pump down one

tank to a user defined level, and then switch over to the

other tank for fuel dispensing. In either case, there must be

at least one submersible pump in each tank.

TS-TPI Overview

The TS-TPI programming function allows the controllers

to be “grouped” together, and be programmed for specific

fuel management options. These options are NONE,

LEVELING, and PRIORITY

• NONE means NO level management for the selected

pump group. (Default setting.)

• LEVELING mode seeks to maintain an equal level

of fuel in each tank by placing pump controllers

associated with the tank containing the most amount

of fuel to priority. This will force the pump installed in

the tank with the highest level of fuel to activate with

the next activation of a dispenser switch.

Note: Leveling is achieved using level as percentage

volume full. The tank gauge will look at levels

in a tank as % full, and will attempt to keep that

number equal between all tanks in LEVELING

mode. If tanks are different sizes, the levels in

tanks may not be equal, but the % full for each

tank will be similar.

• PRIORITY mode tries to pump down one tank before

switching to other tank(s). After choosing PRIORITY

mode, the technician will program the RESERVE

setting. The reserve level is input as a percent full in

the tank. When the RESERVE level is reached for

that tank, priority will switch to the pump in the other

tank. If both tanks are below RESERVE level the ATG

will automatically use Leveling until tanks receive a

delivery of fuel or reach Dry Tank Indication Levels.

Note: In both Leveling and Priority modes, the ATG

chooses which pump will take priority. Because

of this, the pump controllers should be set to

Master-Slave, not Master-Slave / Alternating

Circuit. If the pump controllers are configured for

Master-Slave / Alternating Circuit, the pumps will

not turn on in a predicable manner. Tanks that

are in Leveling or Priority mode are monitored

and tested as separate tanks and should NOT be

siphoned.

Other T5 series TS-TPI functions include;

Overfill Protection: when the LEVELING and PRIORITY

modes are chosen, if a tank level rises above its high level

limit, that tank will become the priority tank, regardless

of what leveling mode is active. If the level in that tank

continues to rise and reaches the high-high limit, all

pumps in the group will be shutdown, except for the pump

in the tank with the high-high alarm. In-line check valves

used to prevent overfill conditions in manifolded tanks,

such as those used with Red Jacket submersible pumps,

are not required or recommended.

Note: The Overfill Protection feature will work correctly

ONLY when the high and high-high level alarms

are programmed correctly. Failure to set high

and high-high level alarms will result in a loss of

overfill protection.

Dry Tank Indication: TS-TPI programming enables the

user to enter a PUMP HEIGHT measurement (default is

5"). This is the distance between the bottom of the pump

motor to the bottom of the tank. When the pump controller

indicates an Under - Load condition and the product

level is within 3" of the programmed PUMP HEIGHT

measurement, an alarm on the tank gauge will indicate

DRY TANK. When a delivery is made, the pump controller

will automatically be reset.

Note: Because the TS-TPI resets the pump controller

after a delivery is made, the Auto Restart feature

on the pump controller must be disabled.

Clogged Intake Indication: The combination of a pump

controller Under-load condition and a tank level that is

at least 3" greater than the programmed PUMP HEIGHT

measurement will cause a BLOCKED INTAKE indication.

Because the tank gauge is able to confirm that there is

fuel in the tank, this alarm indicates a motor intake that is

being blocked by a foreign object.

Pump in Water Indication: If the tank gauge records

a water level that is within 2” of the programmed PUMP

HEIGHT measurement, the pump will become disabled.

The tank gauge will indicate a PUMP IN WATER alarm.