Setting the omr scanning area, Defining the first mark position and code length, Scanning • 8 – Pitney Bowes DI950 FastPac Inserter User Manual

Page 173

SV61311 Rev. E

8-29

Scanning • 8

Material is scanned as it feeds through the machine. This means that the

scanner reads a vertical strip or margin down the page, defined by the spec-

ifications.

The system must now be told if the entire margin (the strip down the page

that is scanned for marks) is clear of any other printing or punched holes,

etc.

• If the area s clear, the machine can normally detect the marks with no

further setup.

• If the entre margn s not clear, or the machne cannot set tself automat-

cally, it will ask questions to ascertain where it needs to look for marks

and where it should ignore other printed matter. Depending on the type

of code being used, the machine will ask you to define either the first

mark position and code length OR the Clear Zone as described on the

following pages.

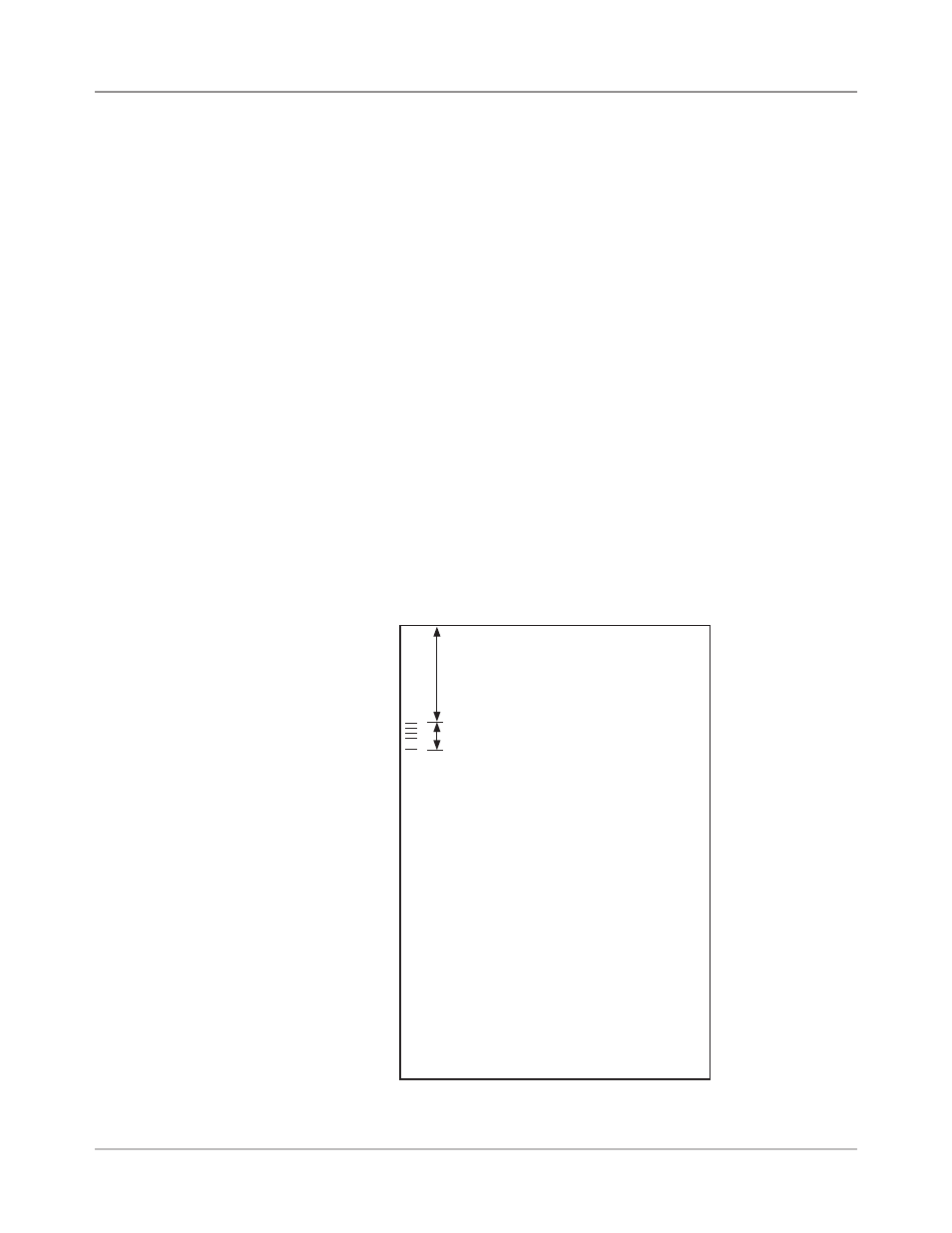

1. Take a sheet that has at least the FIRST and LAST mark printed on it.

2. When requested by the machine, measure and enter the distance (A)

from the top edge of the sheet to the FIRST mark, in millimeters.

3. When requested by the machine, measure and enter the distance (B)

from the FIRST mark to the LAST mark, in millimeters.

A

B

TOP OF SHEET

Defining the

First Mark

Position and

Code Length

Setting the

OMR Scanning

Area