5 • troubleshooting – Pitney Bowes DI950 FastPac Inserter User Manual

Page 100

5-8

SV61311 Rev. E

5 • Troubleshooting

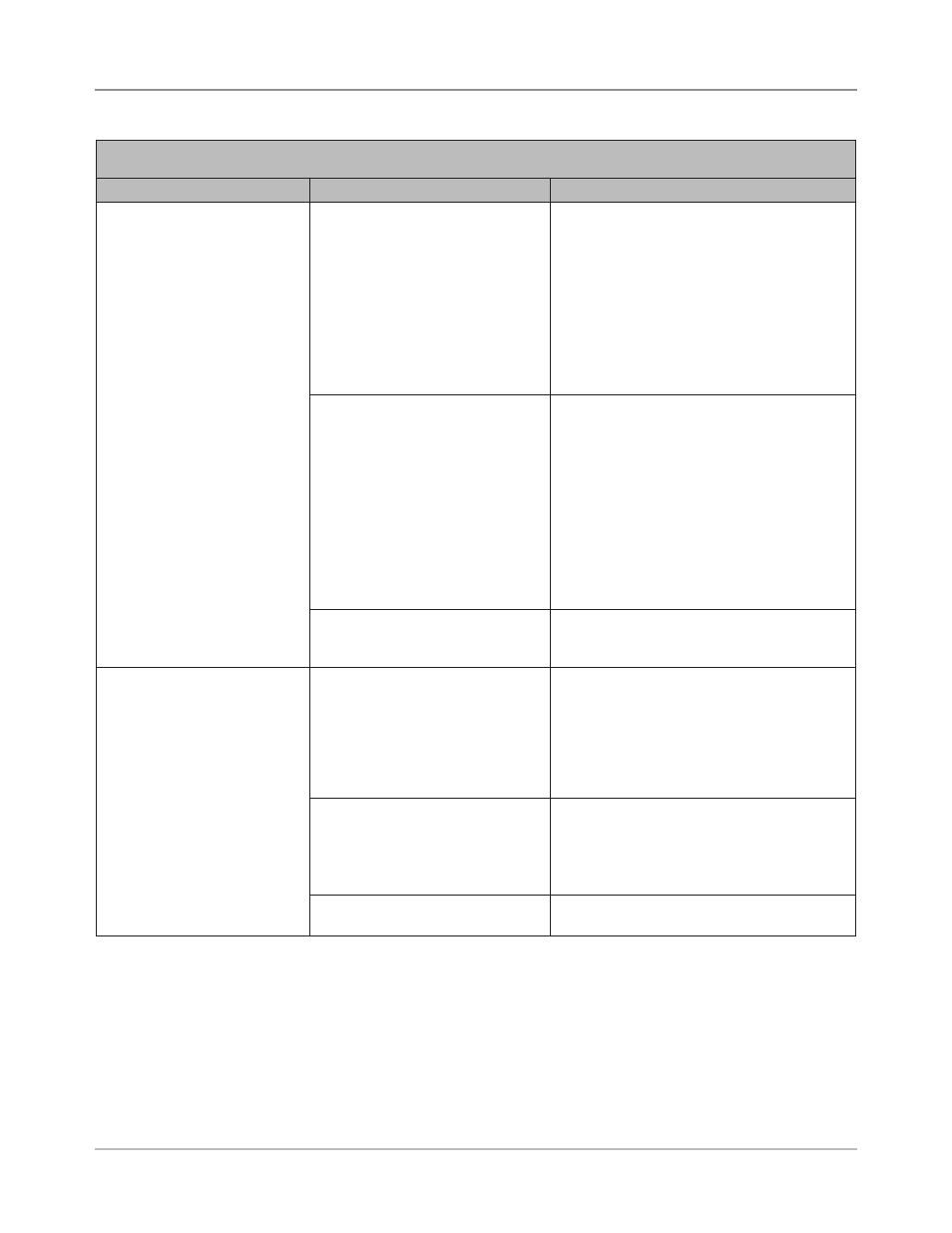

Table 5-3 Tower Feeder Problems

Problem

Cause

Action

Failure to feed.

Material not within specifications.

Check that all material meets published

specifications. Refer to

Feeder Tower Materal Specfcatons in

Chapter 6 of this guide for more information.

•

Remove curled or warped material.

•

Use only material that has been stored

properly.

NOTE: High humidity can make paper limp

and cause curling. Additionally, recycled

material can sometimes be problematic.

Improper loading.

•

Be sure to fan (aerate) material before

loading.

•

Be sure to follow the loading instructions

as suggested on the display screen.

•

Check side guides.

NOTE: Guides set tightly up against

stack can disrupt or prevent material from

feeding.

•

Check that material is loaded in the

correct feeder and in the proper

orientation.

Paper fragments or debris in tray,

rollers or tower transport.

Inspect feed rollers and transport path.

Remove paper fragments before running a

clear deck.

Double or multiple feeds;

stream feeding.

Material not within specifications.

Check that all material meets published

specifications. Refer to Feeder Tower Materal

Specfcatons in Chapter 6 of this guide for

more information.

NOTE: Some glossy materials contain

contaminates that can clog feed rollers and

cause stream or double feeds.

Improper loading.

Be sure to fan (aerate) material before loading,

especially material that has been printed

recently.

NOTE: Low humidity can cause paper to

accumulate a static charge and cling together.

Dirty, worn or glazed feed and/or

retard rollers.

Clean or replace affected rollers. Contact your

system supplier.