5 • troubleshooting – Pitney Bowes DI950 FastPac Inserter User Manual

Page 102

5-10

SV61311 Rev. E

5 • Troubleshooting

Table 5-4 Tower Area Problems

Problem

Cause

Action

Stoppage in tower area.

Material not within

specifications, causing skew.

Check that all material meets published specifications.

Refer to Feeder Tower Materal Specfcatons in

Chapter 6 of this guide for instructions.

•

Remove curled or warped material.

•

Use only material that has been stored properly.

NOTE: High humidity can make paper limp and

cause curling. Additionally, recycled material can

sometimes be problematic.

Improper loading: material

skew caused by Tower

feeders.

Check Side Guide adjustment on Trays. Skewed

material is a common cause of problems in the Tower

area. Refer to Adjustng Tray Sde Gudes in Chapter 3

of this guide for instructions.

Paper fragments or other

obstruction in transport.

Inspect. Clean.

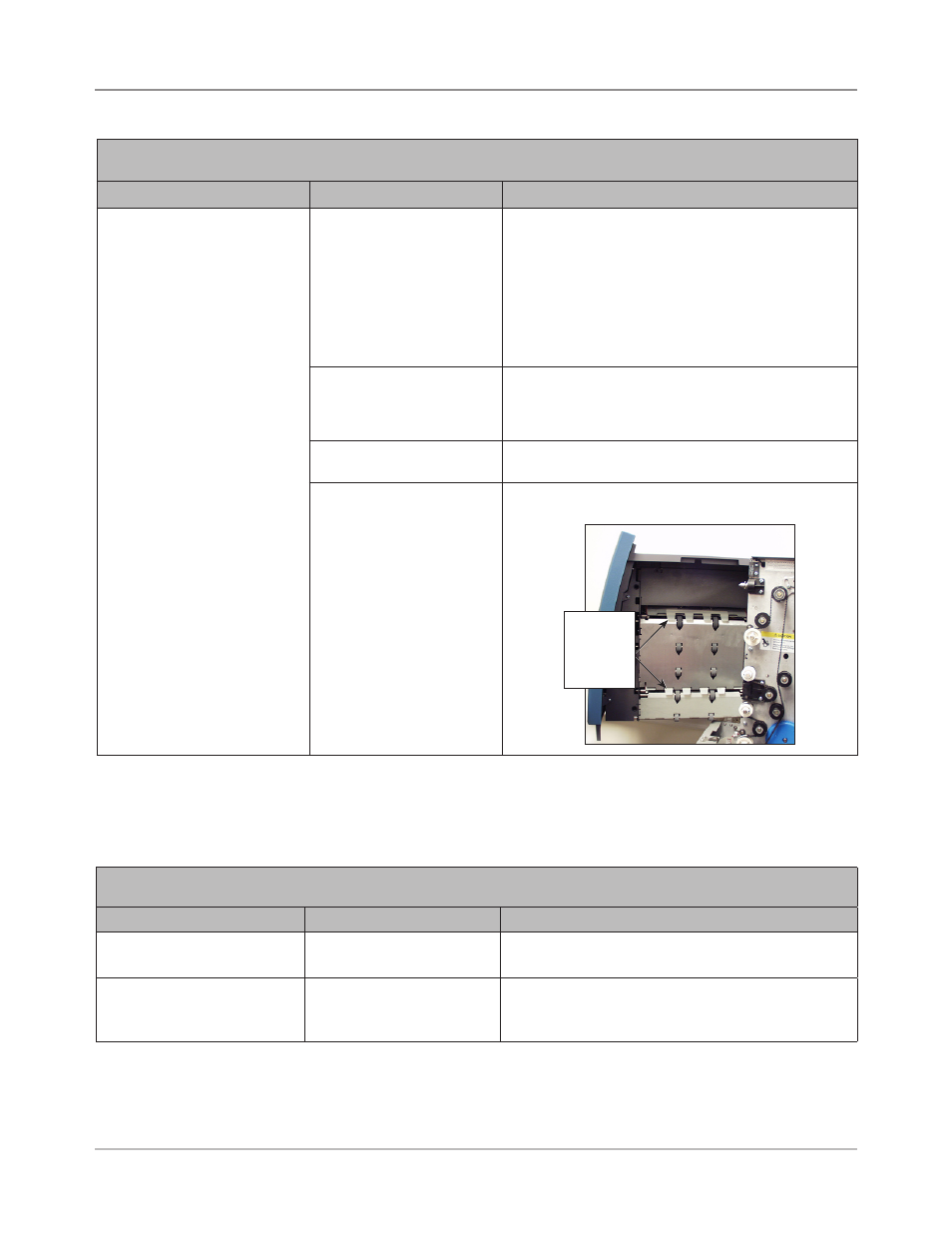

Flexible plastic material

guides in Tower area are

broken or displaced.

Open Tower cover and inspect. If replacement is

necessary, call your system supplier.

Flexible

plastic

material

guides

Table 5-5 Folder/Inverter Problems

Problem

Cause

Action

Stoppage in folder.

Paper fragments.

•

Open Folder and check for obstruction.

•

Remove paper fragments/residues.

Stoppage in inverter.

Material not within

specifications.

Check that material meets specifications.

NOTE: Sets that use the inverter cannot be wider than

225 mm (8.86").