Troubleshooting • 5 – Pitney Bowes DI950 FastPac Inserter User Manual

Page 107

SV61311 Rev. E

5-15

Troubleshooting • 5

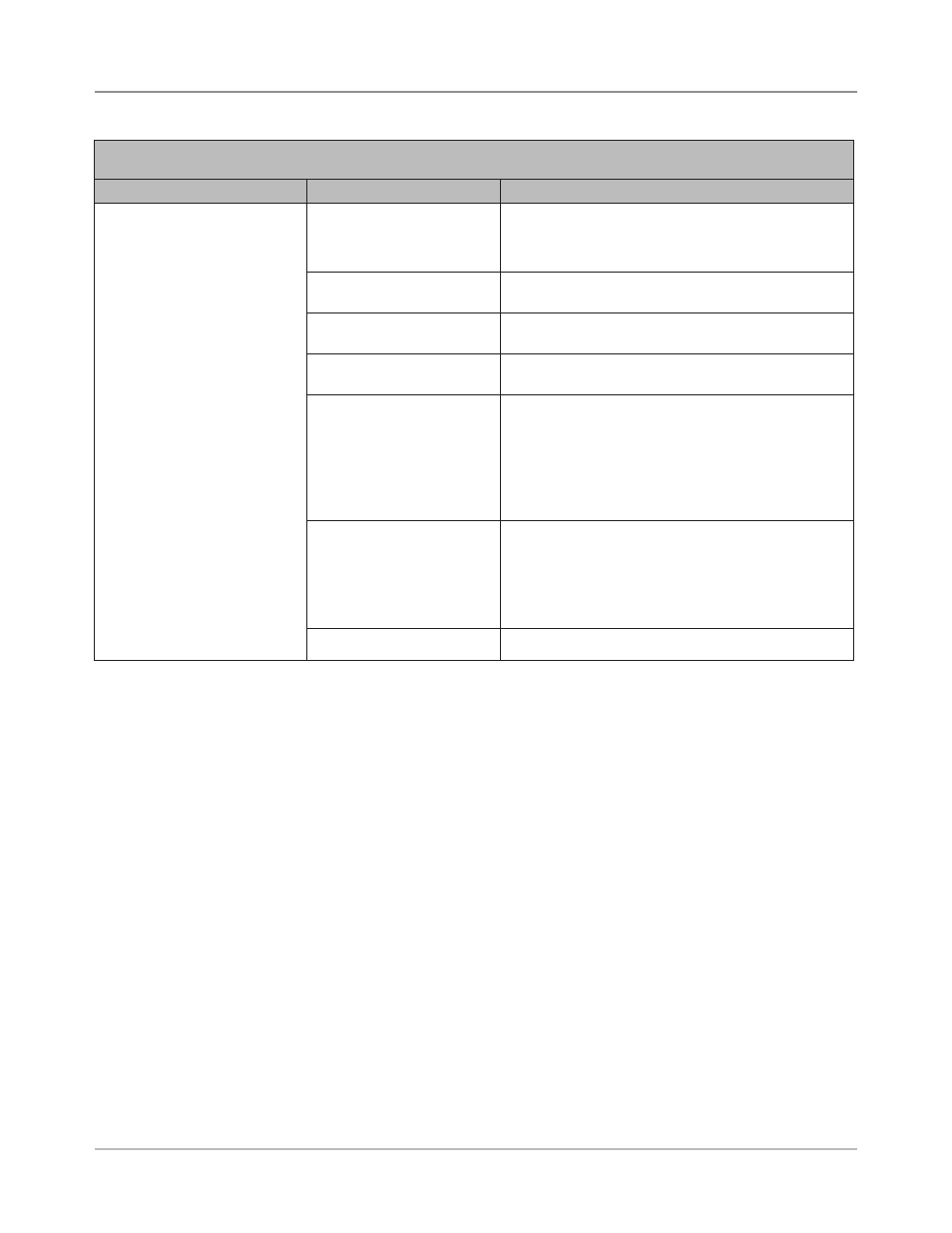

Table 5-10 Scanning Problems

Problem

Cause

Action

Two or more collations are

inserted in a single envelope.

OR

A single collation is broken

in two and inserted into two

envelopes.

OR

System stops and declares an

error.

NOTE: Recommended OMR

thickness is 0.012" to 0.49".

For general information on

Scanner head position

improperly adjusted.

Check position adjustment of scanner head. See

instructions in Chapter 8.

Selected scan definition is

incorrect for job.

Select correct scan definition.

Scan definition incorrectly

set up.

Review scan setup using scan setup options on the

Control Panel.

Material loaded in

incorrect order.

Load material in correct order.

Adverse paper motion. This

refers to any misalignment

of paper that can cause a

misread. It includes paper

skew, paper slippage and

paper offset to one side of

the transport.

Make sure material is properly loaded. In particular,

check the feeder side guides. Check the transport is

free of obstructions.

Poor OMR or barcode

printing. Problems include

insufficient contrast, poor

print quality (voids, fuzzy

printing) and inadequate

clear zones.

Check the mark specifications to make sure OMR

or barcodes are fully compliant. Low toner in laser

and dot matrix printers can cause problems, as can

rough paper. Certain printing methods (such as ion

deposition) can also cause printing problems.

Scanner inoperative.

Contact your system supplier.