TeeJet TASC-6100 User Manual

Page 39

2-23

98-05018

R2

CE & StandardVersion

TASC 6100

Setup

& Cal.

to get an accurate measurement but be careful to

keep the conveyor running full. As an example: if

the truck scale reads in 20 lb. (10 Kg.) increments,

at least 1000 lbs. (500Kg.) must be discharged to

be able to calibrate within 2%.

D. Weigh the truck and load and record this weight.

Back up to a location where you can safely unload

the material through the conveyor.

E. Reset the Total Applied accumulator (see page 2-

11).

F. Dispense the desired amount of material by setting

the console switches as follows:

1. Power

ON

2. Mode Selector

OPERATE

3. Display Selector

Test Speed

4. Rate Switch

Standard Rate

5. Programmed Booms

ON

6. Master Switch

ON

The conveyor will start to discharge. Allow the

conveyor to run until the desired amount has been

discharged.

7. Turn OFF the Master switch.

G. Rotate the Display Selector to Total Applied.

TASC 6100 displays the INDICATED AMOUNT

discharged by the conveyor in lbs (Kg.) or tons if

over 20,000 lbs. (metric tons if over 10,000 Kg.).

H. Weigh the truck and load (be sure the driver's

weight is included if he was on the truck when it

was weighed the first time). The difference

between the starting weight and the ending weight

is the ACTUAL AMOUNT discharged by the

conveyor. (This procedure assumes fuel use is

minimal during the test).

I. To adjust the Spreader Constant, use the following

formula:

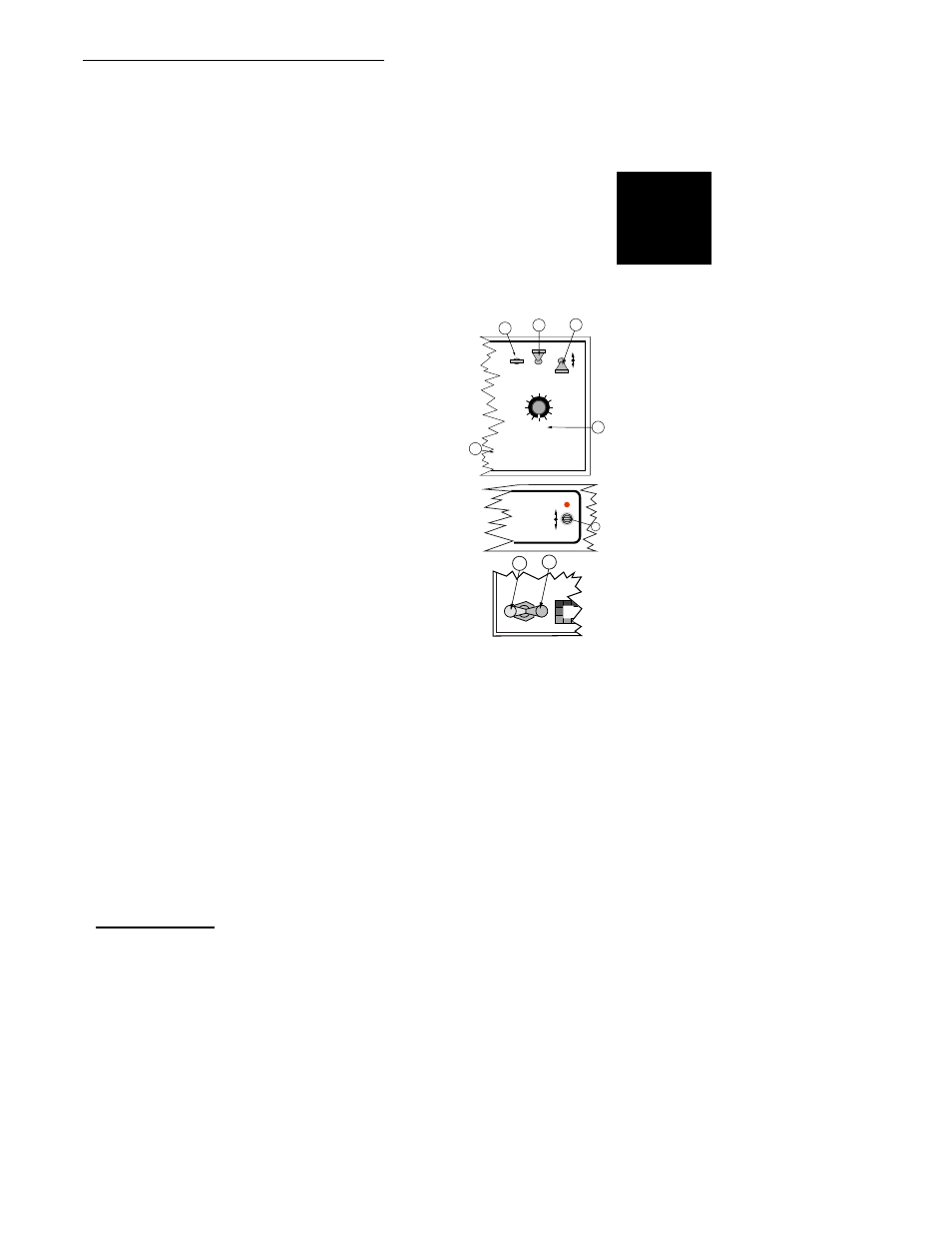

DISPLAY SELECTOR

Speed

Area

Impl. Width

Distance

Test

Speed

PSI/Prime

Total Applied

Application Rate

OFF

SET- UP

DEC.

ON

OPERATE

INC.

Scan

Product Vol.

Fan RPM

BOOMS

1

2 3 4 5 6 7 8 9

% Rate

F-1

F-2

F-3

B

F-4

MASTER

ON

OFF

MI

F-7

F-6

Alt.-Rate

Standard Rate

OFF

F-4

X Current Spreader Constant = New Spreader Constant

Indicated Amount

Actual Amount