Calculating the initial rate sensor cal – TeeJet TASC-6100 User Manual

Page 37

2-21

98-05018

R2

CE & StandardVersion

TASC 6100

Setup

& Cal.

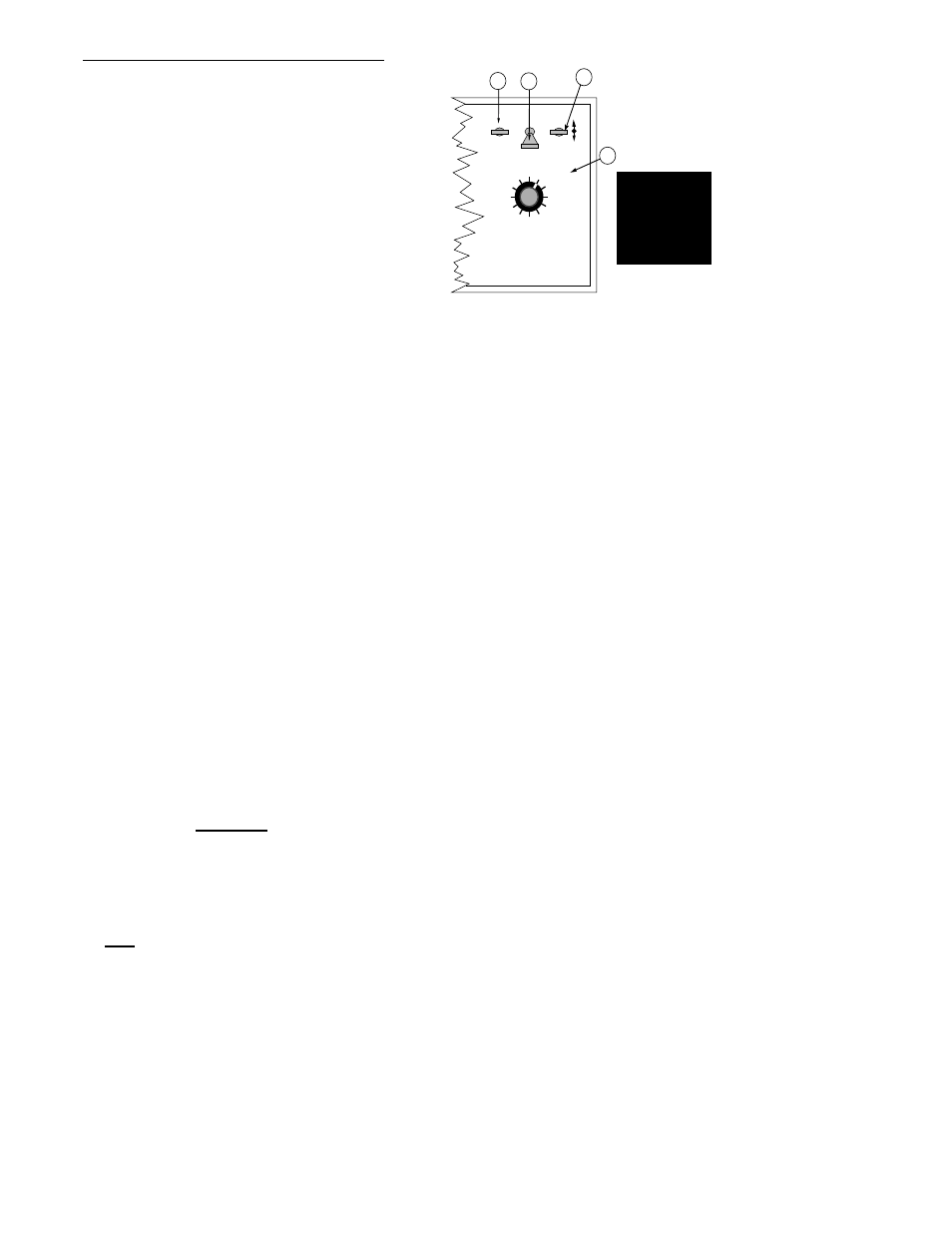

tion of the fan (spinner) must be entered using the

following procedure:

A. Set the console to the following positions;

1. Power

ON

2. Mode Selector

SET- UP

3. Display Selector

Fan RPM

The current Fan Calibration number is displayed.

B. Use the INC./DEC. switch to set this number to the

desired value.

R

ATE

S

ENSOR

C

ALIBRATION

Calculating The Initial Rate Sensor Cal. #

(Spreader Constant)

It is necessary to enter a Spreader Constant in TASC 6100

to ensure an accurate output from the conveyor. The

spreader constant represents the number of sensor pulses

per cubic foot of material discharged. The constant is

different for different gate settings on adjustable spread-

ers. Constants relating to particular gate settings should

be calibrated and recorded for the spreader.

Calculation of the initial spreader constant requires the

following information:

1) Gate height (H) and width (W) in inches

2) Number of sensor pulses for each revolution of the

spreader rate sensor (P)

3) The distance the conveyor moves during one

revolution of the spreader rate sensor (D), in inches.

Calculate the initial spreader constant as follows:

Where: Ft

3

r

is the volume discharged during each

revolution of the spreader rate sensor, in Cubic Feet.

Continue as follows:

DISPLAY SELECTOR

Speed

Area

Impl. Width

Distance

Test

Speed

PSI/Prime

Total Applied

Application Rate

OFF

SET- UP

DEC.

ON

OPERATE

INC.

Scan

Product Vol.

Fan RPM

BOOMS

1 2 3 4 5 6 7 8 9

% Rate

A-2

B

A-3

A-1

D x W x H

1728

= Ft

3

r

P

Ft

3

r

= Initial Calibration Number (Spreader Constant)