Entering the rate sensor calibration number, Fine tuning the rate sensor cal – TeeJet TASC-6100 User Manual

Page 38

2-22

TASC 6100

98-05018

R2

CE & S

TANDARD

V

ERSION

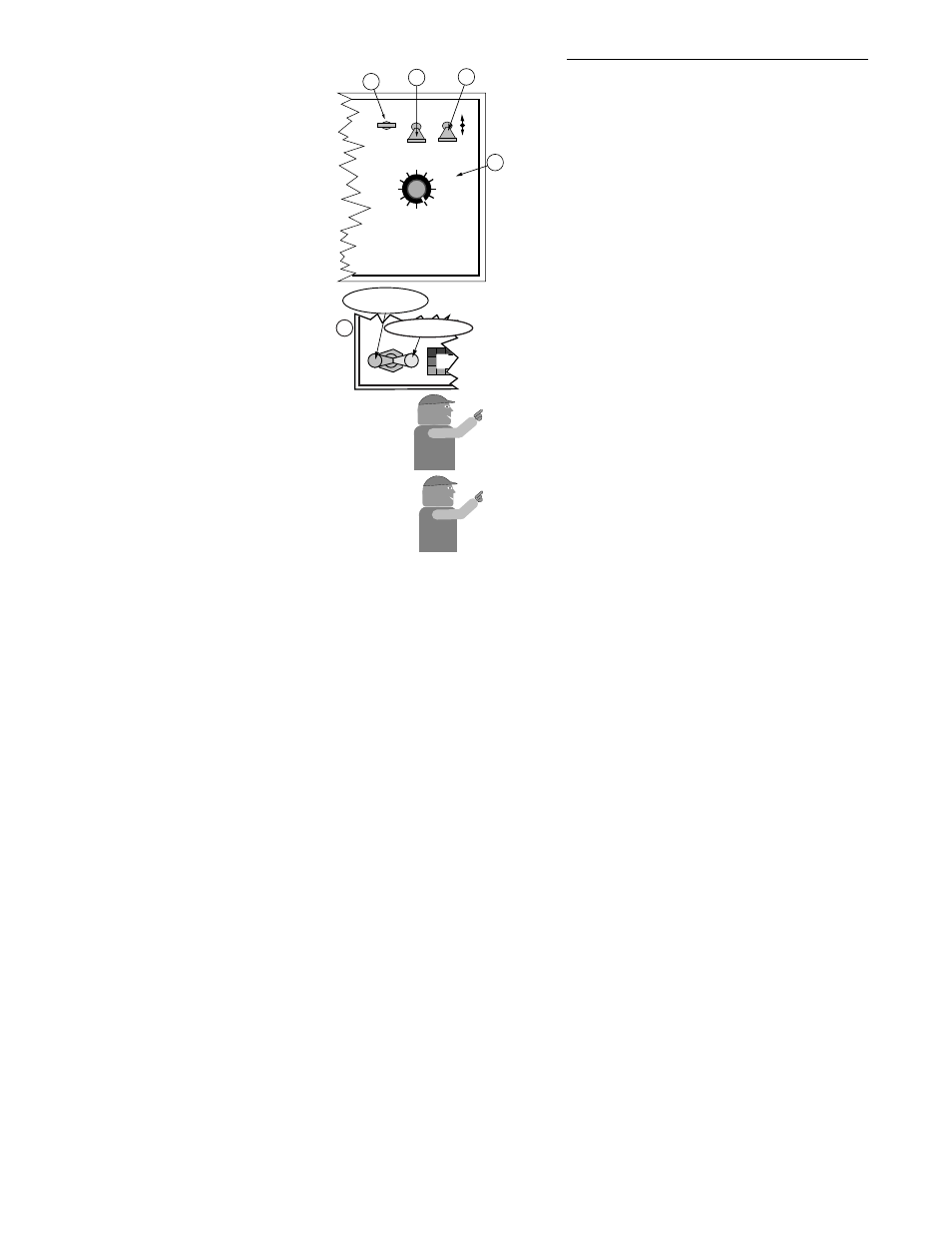

Entering The Rate Sensor Calibration Number

Enter this calibration number into the console using the

procedure that follows.

A. Set the console to the following positions:

1. Power

ON

2. Mode Selector

SET-UP

3. Display Selector

Total Applied

4. Booms

ON

(If Split Drive option is active)

The current Spreader Constant is displayed.

NOTE: If you have a single conveyor bed, the

"Pump C STnrd" application program must be

selected in order to view or set the Spreader

Constant (See page 2-1)

NOTE: If the console is in Split Drive Mode (Pump

C SPLit), the Spreader Constant can only be viewed

or changed when all programmed booms are on.

B. Use the INC./DEC. switch to set the display to the

calculated Spreader Constant.

Fine Tuning The Rate Sensor cal. #

The accuracy of the Spreader Constant should be verified

and adjusted as necessary. The following procedure is

suggested as a simple means of testing the calibration of

the spreader constant. BE SURE THE PROPER PROD-

UCT DENSITY HAS BEEN ENTERED BEFORE PER-

FORMING THE CALIBRATION OR THE RESULTS

WILL BE INACCURATE.

A. Verify the current Spreader Constant (see previous

page). Record this number for reference.

B. Enter the desired application rate (see page 2-3).

C. Load the vehicle with product of known density.

Be sure the Density is properly entered in the

TASC 6100 (see page 2-20). Use enough material

Mid-T

Mid-T

ech

ech

DISPLAY SELECTOR

Speed

Area

Impl. Width

Distance

Test

Speed

PSI/Prime

Total Applied

Application Rate

OFF

SET- UP

DEC.

ON

OPERATE

INC.

Scan

Product Vol.

Fan RPM

BOOMS

1 2 3 4 5 6 7 8 9

% Rate

A-1

A-2

A-3

B

MASTER

ON

OFF

MI

A-4

If using "Pump C rEFLO"

If using "Pump C STnrd"

Mid-T

Mid-T

ech

ech