Controls quick set--up, Accessory installation, Orifice change (48pd only) – Carrier 48/50PD05 User Manual

Page 7: Gas heat (48pd only), Control set point and configuration log, Standard unit control

7

Accessory Installation

Check to make sure that all accessories including sensors have

been installed and wired as required by the instructions and unit

wiring diagrams.

Orifice Change (48PD Only)

This unit is factory assembled for heating operation using natural

gas at an elevation from sea level to 2000 ft.

Use accessory high altitude kit when installing this unit at an

elevation of 2000 to 7000 ft. For elevations above 7000 ft, refer to

High Altitude section to identify the correct orifice size for the

elevation. Purchase these orifices from your local Carrier dealer.

Follow instructions in accessory Installation Instructions to install

the correct orifices.

Use accessory LP (liquid propane) gas conversion kit when

converting this unit for use with LP fuel usage for elevations up

to 7000 ft. For elevations above 7000 ft, refer to High Altitude

section to identify the correct orifice size for the elevation.

Purchase these orifices from your local Carrier dealer. Follow

instructions in accessory Installation Instructions to install the

correct orifices.

Gas Heat (48PD Only)

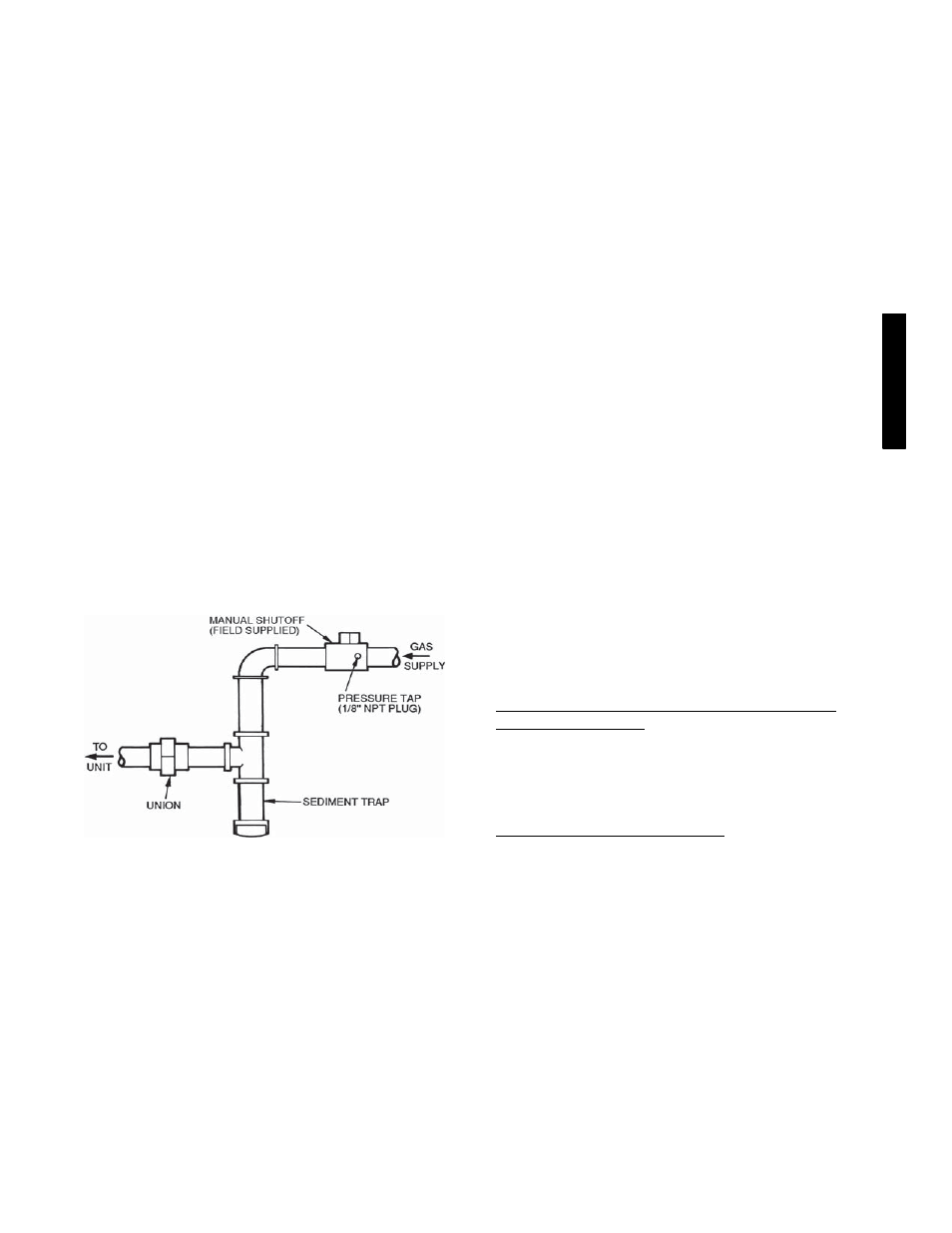

Verify gas pressures before turning on heat as follows:

1. Turn off field-supplied manual gas stop, located external to

unit.

2. Connect pressure gauge to supply gas tap, located on

field-supplied manual shutoff valve. (See F ig. 5.)

3. Connect pressure gauge to manifold pressure tap.

4. Turn on field-supplied manual gas stop. Enter Service Test

mode by setting Service Test→TEST to “ON” using the

Scrolling Marquee display. Use the Service Test feature to

set Service Test→HEAT→HT.1 to ON (first stage of heat)

using the Scrolling Marquee.

C06323

Fig. 5 -- Field Gas Piping

5. After the unit has run for several minutes, verify the supply

gas pressure is between 5.5--in. wg to 13.0--in. wg, and the

manifold pressure is 3.50--in. wg on sizes 03--14 and 3.00

on size 16. If manifold pressure must be adjusted, refer to

Gas Valve Adjustment section.

IMPORTANT: Supply gas pressure must not exceed 13.0--in. wg.

6. Set Service Test→HEAT→HT.1 to OFF using Scrolling

Marquee.

7. Exit Service Test mode by setting Service Test→TEST to

“OFF” using the Scrolling Marquee.

CONTROLS QUICK SET--UP

The following information will provide a quick guide to setting up

and configuring the 48/50PD series units with ComfortLink™

controls. Unit controls are pre-configured at the factory for

factory-installed options. Field-installed accessories will require

configuration at start-up. Service Test is recommended for initial

start--up.

Additionally, specific job requirements may require

changes to default configuration values. See the CCN and Display

parameter tables and other sections of these instructions for more

details.

Control Set Point and Configuration Log

During start up, accessory installation, and equipment service set

points and/or configuration changes might have to be made. When

setting

set

points

or

changing

configuration

settings,

documentation is recommended. The Control Log starting on page

106 should be filled out and left with the unit at all times. A copy

should also be provided to the equipment owner.

Standard Unit Control

There are two different applications these units can be applied to,

Displacement Ventilation and Single Zone VAV.

For either

application a direct wired space sensor can be used or a

communicating sensor/thermostat can be used. Installation of an

accessory supply air temperature (SAT) sensor in the supply duct is

recommended when using a communication type control. A supply

duct SAT measurement is valid for heating mode display, while the

factory--standard internal SAT is not valid for heating due to its

location upstream of the heating section. When installing the

supply duct SAT, the heating mode display is enabled by setting

Configuration→HEAT→SAT→SAT.H to ENBL.

There are several configurations that should be considered for

Displacement Ventilation or Single Zone VAV applications. Table

3 shows these configuration defaults and specific application

settings. These settings typical values and should be adjusted for

each actual specific unit application. Refer to the Operation section

for more detail on these configurations and how they effect the

units operation.

IMPORTANT: Multiple zoning application is not recommended

at this time with the PD product.

Space Temperature Sensor Control—Direct Wired

(T--55, T--56, or T--59)

Wire accessory space temperature sensor(s) to the T--55 terminals

on the field connection terminal board located at the unit control

box. No configuration is required when installing a T--55, T--56, or

T--59. Refer to Field-Installed Accessories section for additional

information.

T--58 Communicating Thermostat

Install the T--58 communicating thermostat. Connect the CCN

communication bus from the T--58 to the CCN terminals on the

field connection terminal board located at the unit control box.

Configure the unit’s CCN communication element number, bus

number, and baud rate. Configure the T--58’s CCN communication

bus number and baud rate the same as the unit, while the element

number has to be different. Configure the T--58 to send SPT to the

unit’s element number. Refer to the Field--Installed Accessories

section for additional information.

48/

50P

D