Digital scroll controller (dsc) troubleshooting – Carrier 48/50PD05 User Manual

Page 31

31

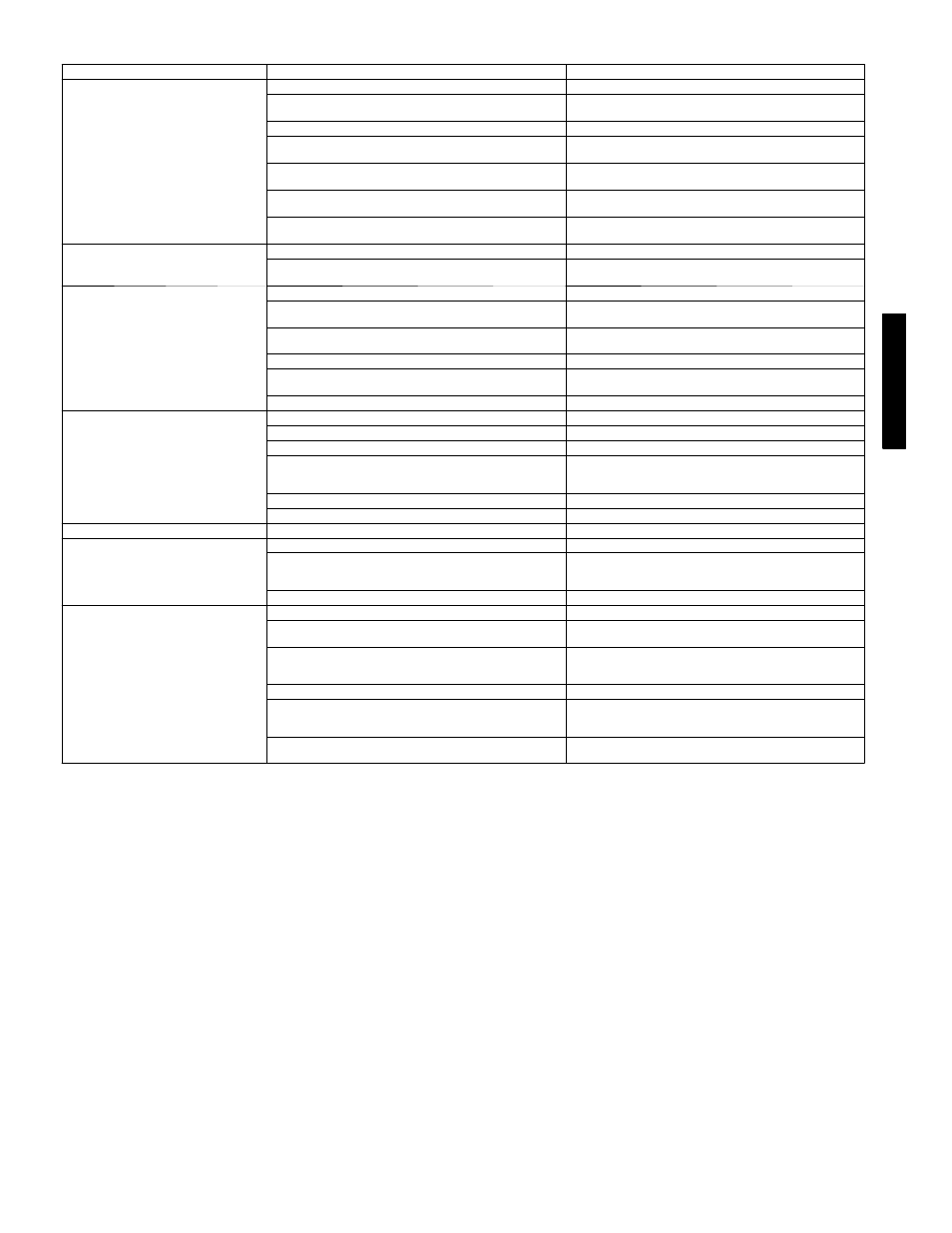

Table 9 — Cooling Service Analysis

PROBLEM

CAUSE

REMEDY

Compressor and Fan Will Not Start Power failure.

Call power company.

Fuse blown or circuit breaker tripped. Check CB1 and

CB2.

Replace fuse or reset circuit breaker.

Disconnect off.

Power disconnect.

Compressor time guard to prevent short cycling.

Check time guards using ComfortLinkt Scrolling

Marquee also the DSC has a 2 minute anti---short time

Occupancy schedule set point or supply set point not

calling for Cooling.

Check cooling demand using ComfortLink Scrolling

Marquee.

Outdoor temperature too low.

Check Compressor Lockout Temperature using

ComfortLink Scrolling Marquee.

Active alarm.

Check active alarms using ComfortLink Scrolling

Marquee and DSC alert flash codes

Compressor Cycles (other than

normally satisfying demand).

Insufficient line voltage.

Determine cause and correct.

Active alarm.

Check active alarms using ComfortLink Scrolling

Marquee and DSC alert flash codes

Compressor Operates

Continuously.

Unit undersized for load.

Decrease load or increase size of unit.

Occupancy schedule set point or supply set point too

low. Compressor running at lowest capacity

Check and adjust set points if needed.

Compressor contactor stuck on

Check cooling demand using ComfortLink Scrolling

Marquee and DSC alert flash codes.

Dirty air filters.

Replace filters.

Low refrigerant charge.

Check pressure, locate leak, repair, evacuate, and

recharge.

Condenser coil dirty or restricted.

Clean coil or remove restriction.

Excessive Condenser Pressures.

Loose condenser thermistors.

Tighten thermistors.

Dirty condenser coil.

Clean coil.

Refrigerant overcharge.

Recover excess refrigerant.

Faulty TXV.

1.Check TXV bulb mounting and secure tightly to suction

line and insulate.

2.Replace TXV (and filter drier) if stuck open or closed.

Condenser air restricted or air short cycling.

Determine cause and correct.

Restriction in liquid tube.

Remove restriction.

Condenser Fans Not Operating.

No Power to contactors.

Fuse blown or plug at motor loose.

Excessive Suction Pressure.

High heat load.

Check for sources and eliminate

Faulty TXV.

1.Check TXV bulb mounting and secure tightly to suction

line and insulate.

2.Replace TXV (and filter drier) if stuck open or closed.

Refrigerant overcharged.

Recover excess refrigerant.

Suction Pressure Too Low.

Dirty air filters.

Replace air filters.

Low refrigerant charge.

Check pressure, locate leak, repair, evacuate, and

recharge.

Faulty TXV.

1.Check TXV bulb mounting and secure tightly to suction

line and insulate.

2.Replace TXV (and filter drier) if stuck open or closed.

Insufficient evaporator airflow.

Check belt tension. Check for other restrictions.

Indoor Fan Running to slow or off while compressor is

on

Check VFD display is illuminated and shows Auto

mode. Power supplied to VFD. Check 0---10vdc signal

present at AUX1 board.

Temperature too low in conditioned area (low

return---air

temperature).

Reset thermostat or occupancy schedule.

LEGEND

CB -- Circuit Breaker

DSC -- Digital Scroll Controller

TXV -- Thermostatic Expansion Valve

VFD -- Variable Frequency Drive

Digital Scroll Controller (DSC) Troubleshooting

The 48/50PD units are equipped with a digital scroll compressor.

The compressor has a solenoid unloader that is controlled by the

digital scroll controller (DSC). This DSC turns the unloader on

and off within a 20 second window. The amount of time the

unloader is on verses off within that 20 seconds depends on the

desired capacity. This means that the ComfortLink control does

not have direct control of the compressor, but it does however

control the power to the DSC and the signal for commanded

capacity.

The DSC has three LED lights to help during troubleshooting;

green, yellow, and red

The DSC will run the compressor

unloaded for a half a second on start up and one second on

shutdown to prevent reverse rotation. A two minute anti--short

time guard is applied by the DSC after shutting the compressor off.

The DSC has an alarm relay output that is connected to the MBB.

When this MBB input switch is closed, the MBB activates the

T051 alert. Check the LED status on the DSC for flash alarm

codes and correct any problems. Table 10 shows the DSC’s Red

LED flash codes.

POWER LED (green) ⎯ indicates voltage is present at the

24VAC power terminal. When the 2 minute anti--short cycle timer

is active, the green LED will flash.

UNLOADED LED (yellow) ⎯ indicates the unloader solenoid

status. The LED is on when the unloader solenoid is energized.

ALERT LED (red) ⎯ communicates an abnormal system

condition through a unique flash code.

All LEDs Flashing at the Same Rate ⎯ indicates 24VAC supply

is too low for operation.

All LEDs On Solid at the Same Time ⎯ indicates Digital Scroll

Controller failure.

Flash Code 1 ⎯ Reserved for future use

Flash Code 2 ⎯ High Discharge Temperature

This occurs when the discharge temperature thermistor (DTT) has

48/

50P

D