Caution – Carrier 48/50PD05 User Manual

Page 61

61

UNIT RELIABILITY HAZARD

Failure to follow this caution may result in reduced unit

performance.

High velocity water from a pressure washer, garden hose, or

compressed air should never be used to clean a coil. The

force of the water or air jet will bend the fin edges and

increase airside pressure drop.

CAUTION

!

Totaline Environmentally Sound Coil Cleaner Application

Instructions

1. Proper eye protection such as safety glasses is

recommended during mixing and application.

2. Remove all surface loaded fibers and dirt with a vacuum

cleaner as described above.

3. Thoroughly wet finned surfaces with clean water and a low

velocity garden hose, being careful not to bend fins.

4. Mix Totaline environmentally sound coil cleaner in a

2

1

/

2

gallon garden sprayer according to the instructions

included with the cleaner. The optimum solution

temperature is 100_F.

IMPORTANT: Do NOT USE water in excess of 130_F, as the

enzymatic activity will be destroyed.

5. Thoroughly apply Totaline® environmentally sound coil

cleaner solution to all coil surfaces including finned area,

tube sheets and coil headers.

6. Hold garden sprayer nozzle close to finned areas and apply

cleaner with a vertical, up-and-down motion. Avoid

spraying in horizontal pattern to minimize potential for fin

damage.

7. Ensure cleaner thoroughly penetrates deep into finned

areas.

8. Interior and exterior finned areas must be thoroughly

cleaned.

9. Finned surfaces should remain wet with cleaning solution

for 10 minutes.

10. Ensure surfaces are not allowed to dry before rinsing.

Reapplying cleaner as needed to ensure 10-minute

saturation is achieved.

11. Thoroughly rinse all surfaces with low velocity clean water

using downward rinsing motion of water spray nozzle.

Protect fins from damage from the spray nozzle.

Condensate Drain Pan

Check and clean each year at the start of the cooling season. In

winter, keep drains and traps dry.

To clean the condensate pan:

1. Disconnect condensate drain system from side or bottom

drain connection.

2. Remove and clean trap.

3. Remove 4 screws securing condensate pan access cover to

unit. Save screws and panel.

4. Slide condensate pan out from unit and clean. Pan is made

of non-corrosive plastic. Use a mild cleaner to remove

heavy deposits of dirt and grime.

5. Replace pan in unit.

6. Replace condensate pan access cover with 4 screws saved

from Step 3.

7. Re-attach and prime condensate trap.

8. Connect condensate drainage system.

INDUCED

DRAFT

MOTOR

COMBUSTION

FAN HOUSING

MAIN GAS

VALVE

MAIN BURNER SECTION

HEAT EXCHANGER

SECTION

ROLLOUT

SWITCH

C07037

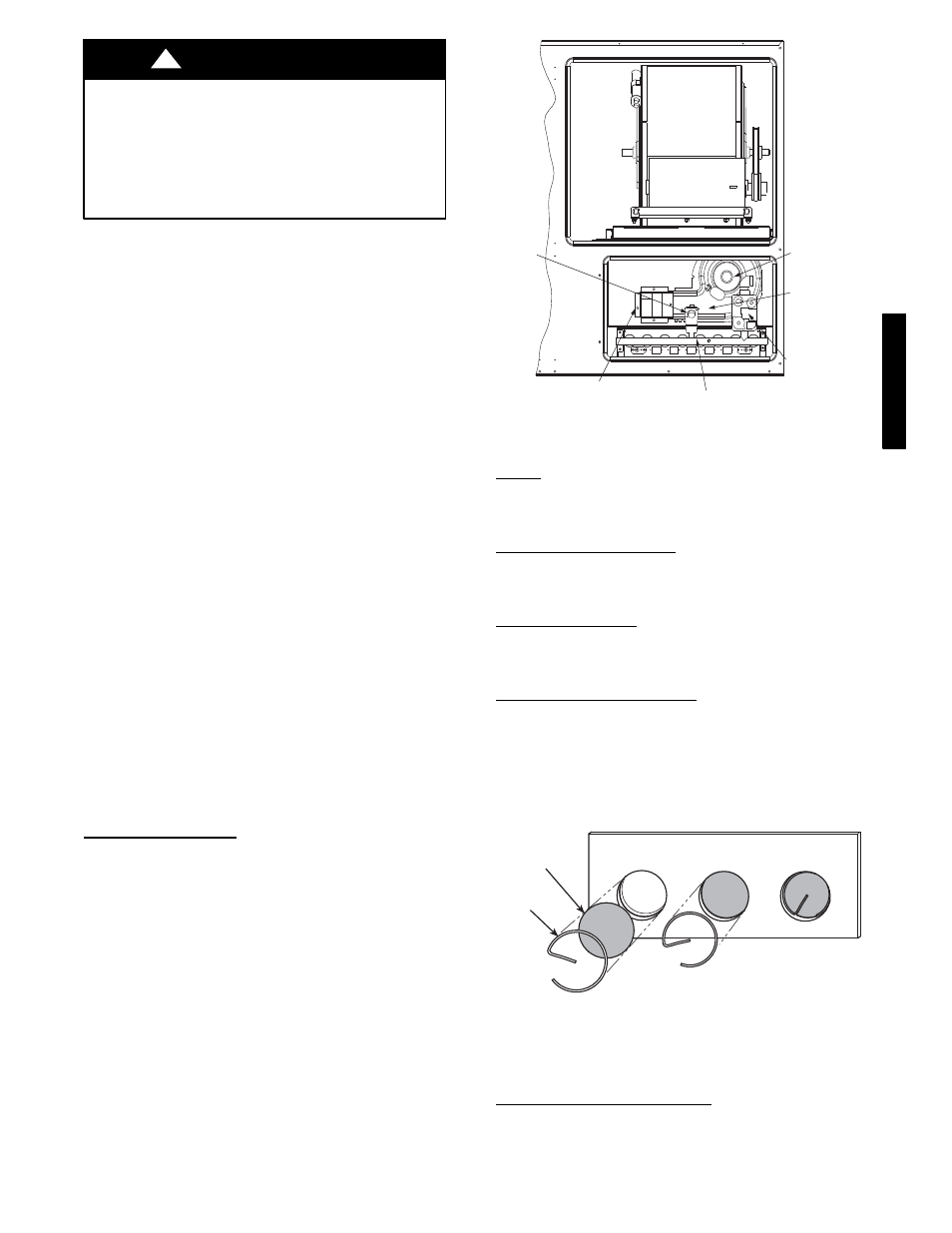

Fig. 28 -- Typical Gas Heating Section

Filters

Clean or replace at start of each heating and cooling season, or

more often if operating conditions require. Refer to unit Installation

Instructions for type and size.

Outdoor--Air Inlet Screens

Clean screens with steam or hot water and a mild detergent. Do

not use throwaway filters in place of screens. See unit installation

instructions for quantity and size.

Main Burner (48PD)

At the beginning of each heating season, inspect for deterioration

or blockage due to corrosion or other causes. Observe the main

burner flames. Refer to Main Burners section.

Flue Gas Passageways (48PD)

The flue collector box and heat exchanger cells may be inspected

by opening heat section access door, flue box cover, and main

burner assembly. (See Fig. 28.) Refer to Main Burners section for

burner removal sequence. If cleaning is required, clean tubes with a

wire brush. Use Caution with ceramic heat exchanger baffles.

When installing retaining clip, be sure the center leg of the clip

extends inward toward baffle. (See Fig. 29.)

CERAMIC

BAFFLE

CLIP

NOTE: One baffle and clip will be in each upper tube of the heat exchanger.

C07260

Fig. 29 -- Removing Heat Exchanger Ceramic

Baffles and Clips

Combustion--Air Blower (48PD)

Clean periodically to assure proper airflow and heating efficiency.

Inspect blower wheel every fall and periodically during heating

season. For the first heating season, inspect blower wheel

bi-monthly to determine proper cleaning frequency.

48/

50P

D