Third party control, Controls operation, Cooling test – Carrier 48/50PD05 User Manual

Page 11: Heating test, Remote occupancy, Fire shutdown, Alarm output, Economizer monitoring, Economizer damper control, Display configuration

11

Cooling Test

The cooling (COOL) submenu is used to change output status for

testing the cooling function. The fans (FANS) and heating (HEAT)

service test outputs are reset to OFF for the cooling service test.

The digital scroll controller power test (CTLR) turns on and off the

compressor controller. The compressor capacity test (CPAC) is

used to run the compressor at a desired capacity of 15% to 100%.

If a capacity is chosen between 1 and 14, the capacity will be set to

15%. The outdoor fan will turn on to high speed when the

compressor capacity is 15% or greater. The indoor fan speed will

default to supply fan maximum speed (FS.MX) when the

compressor capacity test is first activated. The cool test fan speed

(F.SPD) is used to change the fan speed while the compressor is

running. All normal cooling alarms and alerts are functional.

IMPORTANT: When charging the unit, both the compressor

capacity test and the cool test fan speed should be set to 100%.

Heating Test

The heating (HEAT) submenu is used to change output status for

the individual heat stages, gas or electric. The fans (FANS) and

cooling (COOL) service test outputs are reset to OFF for the

heating service test. Indoor and outdoor fans are controlled

normally to maintain proper unit operation. The indoor fan speed

will run at the configured max speed FS.MX. All normal heating

alarms and alerts are functional.

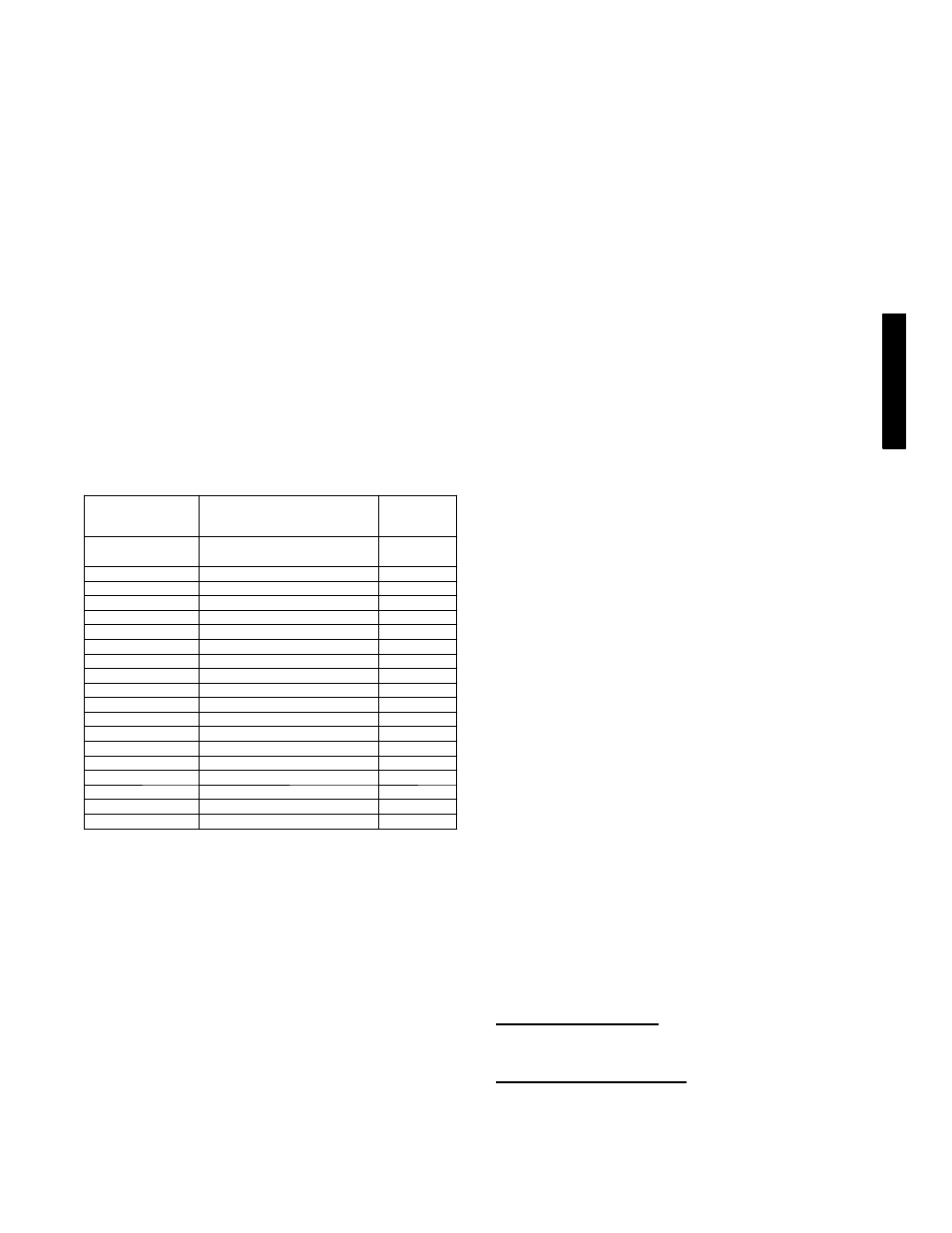

Table 5 — Service Test Modes and Submodes Directory

DISPLAY MENU/

SUB--MENU/

NAME

EXPANDED NAME

VALUES

SERVICE TEST

Field Service Test Mode

On/Off

TEST

INDP

Test Independent Outputs

ECON

Economizer Position Test

0 to 100%

E.CAL

Calibrate Economizer

On/Off

PE.1

Power Exhaust 1 Test

On/Off

PE.2

Power Exhaust 2 Test

On/Off

ALRM

Alarm Relay Test

On/Off

CCH

Crankcase Heat Test

On/Off

FANS SUPPLY

Test Fans

IDF

VFD Power Test

On/Off

F.SPD

Indoor Fan Speed Test

0 to 100%

OFC.1

Outdoor Fan Relay Test

On/Off

COOL

Test Cooling

CTLR

Dig Scroll Ctrl Pwr Test

On/Off

CAPC

Compressor Capacity Test

0 to 100%

F.SPD

Cool Test Fan Speed

0 to 100%

HEAT

Test Heating

HT.1

Heat Stage 1 Test

On/Off

HT.2

Heat Stage 2 Test

On/Off

THIRD PARTY CONTROL

Third party controls may interface with the unit ComfortLinkt

controls through the connections described below. See other

sections of these instructions for more information on the related

unit control and configurations.

Remote Occupancy

The remote occupancy input is provided on the field connection

terminal board (TB1). The Remote Occupancy Switch

configuration, Configuration→UNIT→RM.SW, identifies the

normally open or normally closed status of this input when

unoccupied.

S

5 = 24 VAC signal input

S

6 = 24 VAC source for dry contact

Fire Shutdown

The fire shutdown input is provided for unit shutdown in response

to a fire alarm or smoke detector. The Fire Shutdown Switch

configuration, Configuration→UNIT→FS.SW, identifies the

normally open or normally closed status of this input when there is

no fire alarm.

Input at field connection terminal board (TB1)

S

Fire Shutdown 1 = 24 VAC source for dry contact

S

Fire Shutdown 2 = 24 VAC signal input

Alarm Output

The alarm output is provided on the field connection terminal

board (TB1) to indicate a current alarm status. The output will be

24VAC if a current alarm exists.

S

C = 24 VAC common

S

X = 24 VAC signal output

Economizer Monitoring

On field terminal board (TB1), terminals 8, 9, and 10 can be used

to monitor economizer position from a third party control system.

See economizer operation section for additional information.

In digital mode (E.CTL = 1 or 2), the economizer commanded

position can be read as a 2--10v or 4--20mA signal. TB1--8 and

TB1--9 are used as follows:

S

To read a 2--10v signal, disconnect the violet wire on

TB1--J10--8 and place volt meter device across TB1--8 and

TB1--9.

S

To read a 4--20mA signal, disconnect the violet wire on

TB1--J10--8 and the 500Ω resister at TB1--J10--6. Place amp

meter device between TB1--8 and TB1--9.

In analog mode (E.CTL = 3), the economizer position can be read

as a 2--10v feedback signal across TB1--10 and TB1--9 at any time.

IMPORTANT:

The violet wire and 500Ω resister must be

connected at the J10 connector as originally wired to operate the

economizer in analog mode.

Economizer Damper Control

For units with the economizer option or accessory and the ECB

control board, the damper position can be directly controlled

through the IAQ sensor input provided on the field connection

terminal board. The

IAQ Analog

Input configuration,

Configuration→AIR.Q→IA.CF will have to set to 3 (Control

Minimum Position). When IA.CF = 3, an external 4 to 20 mA

source is used to move the damper 0% to 100% directly.

Terminal 2 = 4--20mA + signal

Terminal 3 = 4--20mA -- common

IMPORTANT:

In this mode preset minimum positions

configurations are not valid. The damper position may exceed the

input position to provide economizer cooling and CO

2

sensor input

can not be used for DCV control. Refer to the Indoor Air Quality

operation section for more information.

CONTROLS OPERATION

Display Configuration

The Configuration→DISP submenu is used to configure the local

display settings.

Metric Display (METR)

This variable is used to change the display from English units to

Metric units.

Language Selection (LANG)

This variable is used to change the language of the ComfortLink

display. At this time, only English is available.

48/

50P

D