Carrier 48/50PD05 User Manual

Page 32

32

measured a temperature above 268 F (131 C) or the thermistor has

short circuited (jumpered out).

The DSC will de--energize the compressor contactor and unloader

solenoid, and the alarm relay contacts will close causing a T051

alert on the ComfortLink Control.

The compressor will be

allowed to restart after 30 minute delay and after the DTT reads

below 250 F (120 C). The flash code and alarm relay contacts will

be reset after the compressor has run for 60 minutes without any

other ALERTs.

If five discharge temperature ALERTs have

occurred within four hours, the DSC will lock out the compressor.

The lockout can only be reset by cycling the 24VAC power off and

on.

Flash Code 3 ⎯ Compressor Protector Trip

This occurs when the demand signal from the system controller is

greater than 1.44VDC and there is no compressor current detected.

This could be due to the compressor’s internal overload protector

being open, fuse or breaker open, power disconnected to

compressor contactor, compressor power wiring not run through

DSC current transformer port or a compressor contactor failure.

The DSC will de--energize the compressor contactor and unloader

solenoid and the alarm relay contacts will close causing a T051

alert on the ComfortLink Control. The DSC will wait for the two

minute anti--short cycle timer to time out and if the system

controller demand signal is still greater than 1.44VDC, energize the

compressor contactor again. If compressor current is detected on

the restart, the ALERT code and alarm relay output will reset. The

DSC will attempt to restart compressor as long as the system

controller demand is above 1.44VDC. There is no lockout feature

for this ALERT.

Flash Code 4 ⎯ Locked Rotor

A locked rotor condition in the compressor is sensed by the DSC

on four consecutive start ups. The DSC will de--energize the

compressor contactor and unloader solenoid and the alarm relay

contacts will close causing a T051 alert on the ComfortLink

Control. This code results in a lockout and can only be reset by

cycling the 24VAC power off and on.

Flash Code 5 ⎯ Demand Signal Loss

This occurs when the demand signal input has dropped below

0.5VDC. The demand input signal wire may be disconnected or

the system controller providing the signal may not be powered.

The DSC will de--energize the compressor contactor and unloader

solenoid and the alarm relay contacts will close causing a T051

alert on the ComfortLink Control. Once the system controller

demand signal input has risen above 0.5VDC, the ALERT code

and alarm relay output will reset. If the demand signal is above

1.44VDC and the anti--short cycle timer has timed out, the

compressor will restart.

Flash Code 6 ⎯ Discharge Thermistor Fault

This occurs when the DSC is not receiving a signal from the

discharge temperature thermistor (DTT). The thermistor may be

missing, disconnected or a wire broken. The alarm relay contacts

will close and the DSC will not increase the capacity of the

compressor beyond 50% loading. This ALERT code and alarm

relay output are reset by reconnecting the DTT.

Flash Code 7 ⎯Reserved for future use

Flash Code 8 ⎯ Compressor Contactor Fault

This occurs when the compressor current is detected when the

system controller demand signal is below 1.44VDC. The

compressor contactor may have welded contacts or the contacts

may be mechanically jammed. The compressor will continue to run

in this condition since the DSC cannot open the compressor

contactor. The DSC will energize the compressor contactor and the

alarm relay contacts will close causing a T051 alert on the

ComfortLink Control. The unloader solenoid will remain

energized causing the compressor to run unloaded as long as the

system controller demand signal is less than 1.44VDC. If the

system controller demand is greater than 1.44VDC, the unloader

solenoid will de--energize causing the compressor to run loaded.

The ALERT code and alarm relay output are reset when current is

no longer detected while system controller demand signal is below

1.44VDC.

Flash Code 9 ⎯ Low 24VAC Supply

This occurs when the supply voltage to the DSC has dropped

below 18.5VDC.

The DSC will de--energize the compressor

contactor and unloader solenoid. The alarm relay contacts may

close if the voltage is high enough for the alarm relay to pull in.

The ALERT code and alarm relay output are reset when the supply

voltage to the DSC rises above 19.5VAC.

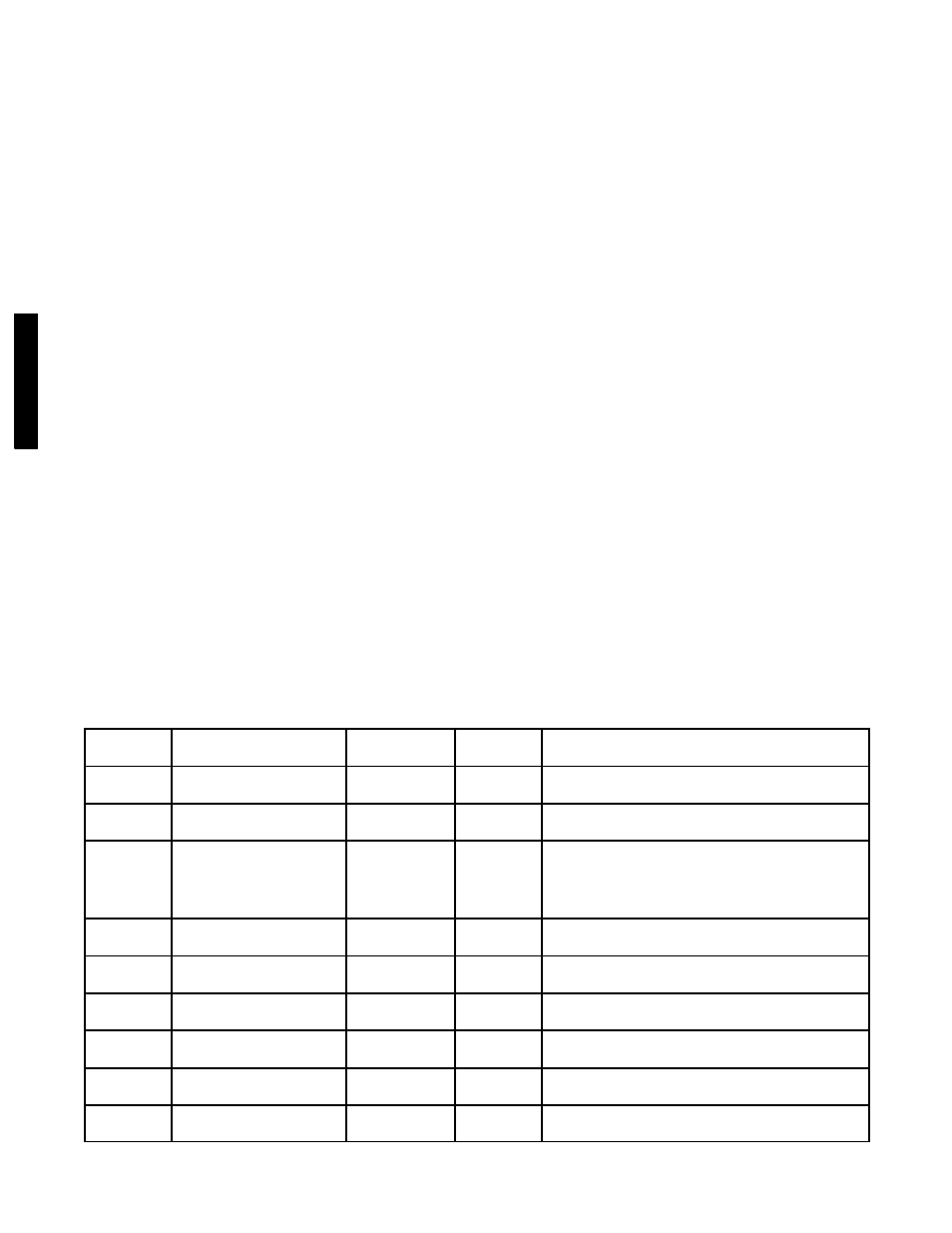

Table 10 — DSC Red LED Flash Codes

LED Flash

Code

Description

Action Taken

by Control

Reset

Method

Probable Cause

1

Flash

Reserved for Future Use

N/A

N/A

N/A

2

Flash

High Discharge Temperature

Compressor

shutdown

Automatic

Compressor discharge temperature is greater then 268

degrees F or the DTT is shorted.

3

Flash

Compressor Protector Trip

Compressor

shutdown

Automatic

Compressor’s internal overload protector being open,

fuse or breaker open, power disconnected to compres-

sor contactor, compressor power wiring not run through

DSC current transformer port or a compressor contactor

failure.

4

Flash

Locked Rotor

Compressor

lockout

Manual

Four consecutive start ups with locked rotor.

5

Flash

Demand Signal Loss

Compressor

shutdown

Automatic

Signal wire may be disconnected or the system control-

ler providing the signal may not be powered

6

Flash

Discharge Thermistor Fault

Capacity Limited

Automatic

DTT may be missing, disconnected or a wire broken

7

Flash

Reserved for Future Use

N/A

N/A

N/A

8

Flash

Compressor Contactor Fault

Keep capacity

at 15%

Automatic

Compressor contactor may have welded contacts or the

contacts may be mechanically jammed

9

Flash

Low 24VAC Supply

Compressor

shutdown

Automatic

Bad connection or transformer.

48/

50P

D