Appendix d -- additional start--up data – Carrier 48/50PD05 User Manual

Page 100

100

APPENDIX D -- ADDITIONAL START--UP DATA

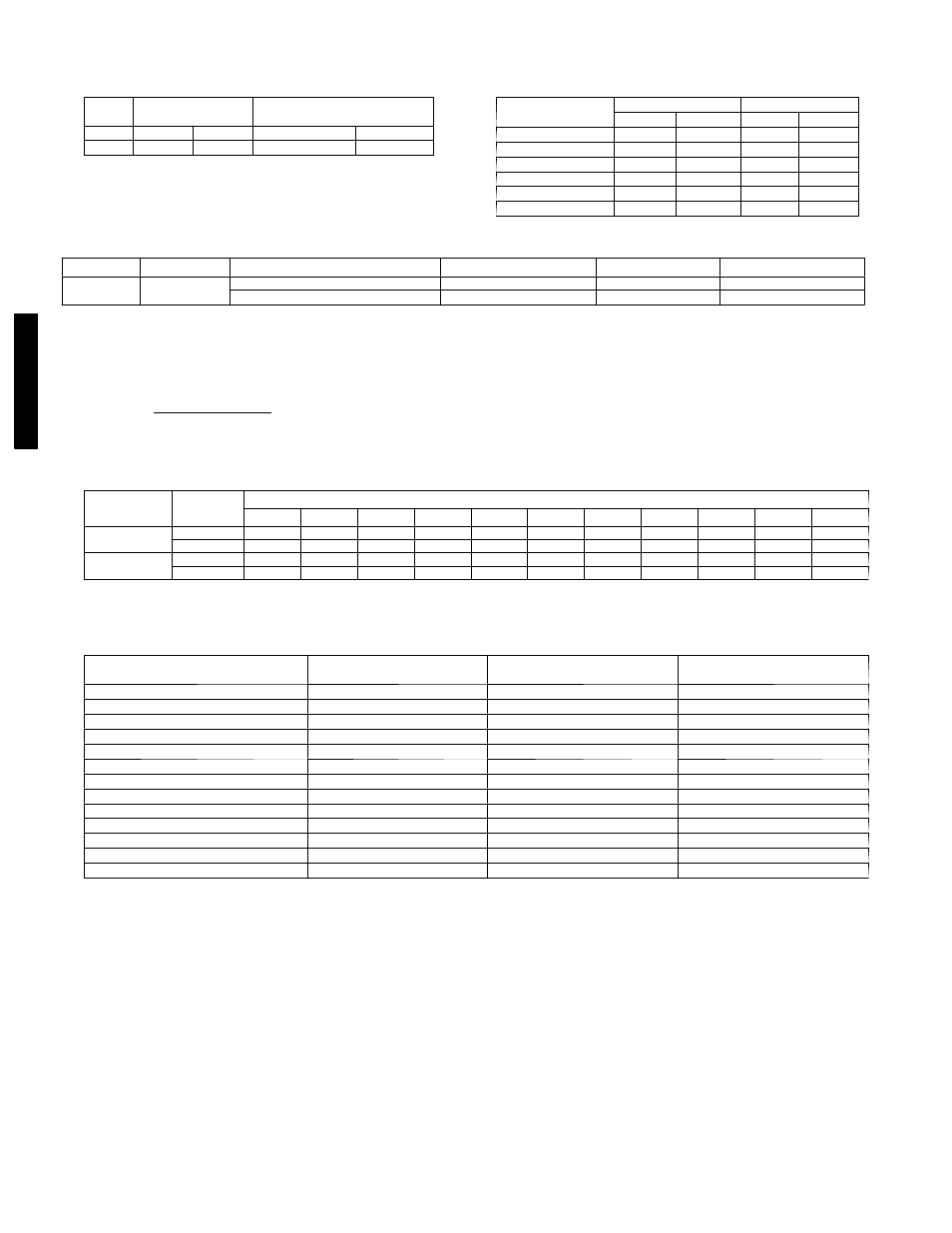

Table 60 — Air Quantity Limits (50PD Units)

UNIT

50PD

COOLING (cfm)

HEATING (cfm)

OPTIONAL ELECTRIC HEAT

05

1200

2000

1200

2000

06

1500

2500

1500

2500

Table 61 — Air Quantity Limits (48PD Units)

UNIT

48PD

COOLING (cfm)

HEATING (cfm)

Min

Max

Min

Max

05 (Low Heat)

1200

2000

600

1680

05 (Med Heat)

1200

2000

940

2810

05 (High Heat)

1200

2000

1130

2820

06 (Low Heat)

1500

2500

940

2810

06 (Med Heat)

1500

2500

1130

2820

06 (High Heat)

1500

2500

1510

2520

Table 62 — Evaporator Fan Motor Specifications - 48/50PD

48/50PD

DRIVE

VOLTAGE/PHASE

EFFICIENCY

MAX BHP

MAX AMPS

05 & 06

Low & High

208/230---3ph

0.80

2.0

6.4

460---3ph

0.80

2.0

3.2

NOTES:

1. Extensive motor and electrical testing ensures that the motors can be utilized

with confidence up to the maximum applied bhp, watts, and amps. Using the fan

motor up to the maximum ratings shown will not result in nuisance tripping or

premature motor failure. Unit warranty will not be affected.

2. Convert bhp to watts using the following formula:

watts =

bhp (746)

motor efficiency

3. The EPACT (Energy Policy Act of 1992) regulates energy requirements for

specific types of indoor-fan motors. Motors regulated by EPACT include any

general purpose, T-frame (three-digit, 143 and larger),

single-speed, foot

mounted, polyphase, squirrel cage induction motors of NEMA (National Electrical

Manufacturers Association) design A and B, manufactured for use in the United

States. Ranging from 1 to 200 Hp, these continuous-duty motors operate on 230

and 460 volt, 60 Hz power. If a motor does not fit into these specifications, the

motor does not have to be replaced by an EPACT-compliant energy-efficient motor.

Variable-speed motors are exempt from EPACT compliance requirements.

Therefore, the indoor-fan motors for Carrier 48/50PG03--14 units are exempt from

these requirements.

Table 63 — Fan Rpm at Motor Pulley Settings* - 48/50PD

UNIT

48/50PD

DRIVE

MOTOR PULLEY TURNS OPEN

0

1

/

2

1

1

1

/

2

2

2

1

/

2

3

3

1

/

2

4

4

1

/

2

5

05

Low

910

878

847

815

784

753

721

690

659

627

596

High

1173

1139

1104

1070

1035

1001

966

932

897

863

828

06

Low

978

949

920

891

863

834

805

776

748

719

690

High

1261

1227

1194

1161

1128

1095

1062

1028

995

962

929

*Approximate fan rpm shown, based on 1725 rpm motor.

NOTE: Factory speed setting is at 5 turns open.

Table 64 — Accessory/FIOP Pressure Drop (in. wg) - 48/50PD

AIRFLOW

(CFM)

ELECTRIC

HEAT

ECONOMIZER

(Vertical)

ECONOMIZER

(Horizontal)

600

0.01

0.01

0.03

800

0.01

0.01

0.05

1000

0.02

0.02

0.07

1200

0.02

0.03

0.10

1400

0.03

0.04

0.14

1600

0.04

0.06

0.17

1800

0.05

0.07

0.22

2000

0.07

0.09

0.26

2200

0.08

0.11

0.31

2400

0.10

0.13

0.37

2600

0.11

0.15

0.43

2800

0.13

0.18

0.49

3000

0.15

0.21

0.56

48/

50P

D