Warning, Verify sensor performance, Economizer operation during power failure – Carrier 48/50PD05 User Manual

Page 64: Evacuation, Refrigerant charge

64

C08570

Fig. 33 -- Condenser--Fan Adjustment

Verify Sensor Performance

Verify that thermistor, transducer, and switch inputs are reading

correctly. These values can be accessed through the Scrolling

Marquee display in the Temperatures, Pressures, and Inputs menus.

Some values will depend on configuration choices. Refer to the

Control Set Up Checklist completed for the specific unit

installation and to the configuration tables in Appendix A.

Economizer Operation During Power Failure

Dampers have a spring return. In event of power failure, dampers

will return to fully closed position until power is restored. Do not

manually operate damper motor.

Evacuation

Proper evacuation of the system will remove noncondensables and

ensure a tight, dry system before charging. Evacuate from both

high and low side ports. Never use the system compressor as a

vacuum pump. Refrigerant tubes and indoor coil should be

evacuated to 500 microns. Always break a vacuum with dry

nitrogen. The two possible methods are the deep vacuum method

and the triple evacuation method.

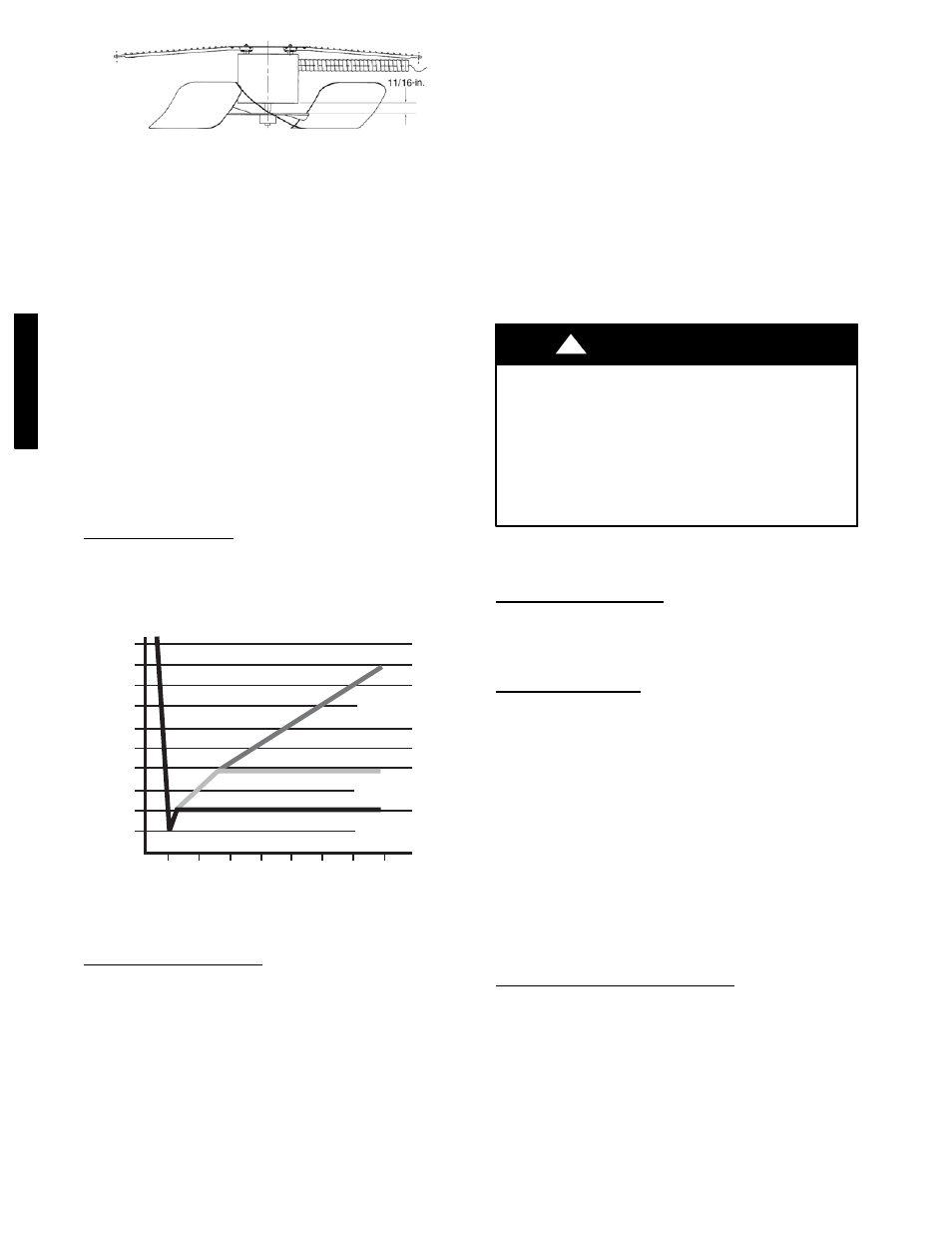

Deep Vacuum Method

The deep vacuum method requires a vacuum pump capable of

pulling a minimum vacuum of 500 microns and a vacuum gauge

capable of accurately measuring this vacuum depth. The deep

vacuum method is the most positive way of assuring a system is

free of air and liquid water. (See Fig. 34.)

LEAK IN

SYSTEM

VACUUM TIGHT

TOO WET

TIGHT

DRY SYSTEM

0

1

2

3

4

5

6

7

MINUTES

5000

4500

4000

3500

3000

2500

2000

1500

1000

500

MICRONS

C06264

Fig. 34 -- Deep Vacuum Graph

Triple Evacuation Method

The triple evacuation method should only be used when vacuum

pump is capable of pumping down to 28--in. of mercury and

system does not contain any liquid water. Proceed as follows:

1. Pump system down to 28--in. of mercury and allow pump

to continue operating for an additional 15 minutes.

2. Close service valves and shut off vacuum pump.

3. Connect a nitrogen cylinder and regulator to system and

open until system pressure is 2 psig.

4. Close service valve and allow system to stand for 1 hr.

During this time, dry nitrogen will be able to diffuse

throughout the system, absorbing moisture.

5. Repeat this procedure. System will then contain minimal

amounts of contaminants and water vapor.

Refrigerant Charge

Amount of refrigerant charge is listed on unit nameplate. Refer to

Carrier GTAC II; Module 5; Charging, Recovery, Recycling, and

Reclamation section for charging methods and procedures. Unit

panels must be in place when unit is operating during charging

procedure.

Puron® (R-410A) refrigerant systems should be charged with

liquid refrigerant. Use a commercial type metering device in the

manifold hose.

UNIT OPERATION AND SAFETY HAZARD

Failure to follow this warning could cause personal

injury, death and/or equipment damage.

Puron (R--410A) refrigerant systems operate at higher

pressures than standard R--22 systems. Do not use R--22

service equipment or components on Puron refrigerant

equipment. Gauge set, hoses, and recovery system must

be designed to handle Puron refrigerant. If unsure

about equipment, consult the equipment manufacturer.

!

WARNING

IMPORTANT: Do not use recycled refrigerant as it may contain

contaminants.

No Charge in the System

Use standard evacuating techniques. After evacuating system,

weigh in the specified amount of refrigerant (refer to unit

nameplate). Verify charge using the charging chart via “Charge in

the System.”

Charge in the System

IMPORTANT: The circuit must be running in normal cooling

mode with the compressor capacity at 100%. The VFD must be

running at max fan speed and indoor airflow must be within

specified air quantity limits for cooling (See Appendix D). All

outdoor fans must be on and running at high speed. Use the

Cooling Service Test Outdoor Fan Override function to start all

outdoor fans.

An accurate pressure gauge and temperature--sensing device is

required. Charging is accomplished by ensuring the proper amount

of liquid subcooling. Connect pressure gauge to the compressor

discharge service valve. Connect temperature sensing device to the

liquid line between the condenser and the TXV (thermostatic

expansion valve), and insulate it so that ambient temperature does

not affect reading. Use the cooling charging chart (Fig. 35--36) to

determine if additional charge is needed or if some charge needs to

be removed from the system.

To Use the Cooling Charging Chart

Use the temperature and pressure readings, and find the

intersection point on the cooling charging chart. If intersection

point on chart is above line, add refrigerant. If intersection point on

chart is below line, carefully recover some of the charge. Recheck

suction pressure as charge is adjusted.

48/

50P

D