Gas valve adjustment, Puron r refrigerant, In. pipe plug and screw cap – Carrier 48/50PD05 User Manual

Page 65

65

The TXV is set to maintain between 10 and 15 degrees of

superheat at the compressors. The valves are factory set and cannot

be adjusted. Do not use A TXV designed for use with R--22.

R4

R410A RE

REFRI

RIGERANT

RANT

OUTDOOR F

R FAN M

N M UST BE OPERATING ON H

N HIGH S

H SPEED

20

20

40

40

60

60

80

80

10

100

12

120

14

140

16

160

150

150

200

200

25

250

300

00

350

350

400

400

450

450

500

500

550

550

600

600

Co mp re ss

ssor Disc

isc h a rg e P re ss

ssu re , [p sig

sig]

Add

dd Cha

harge if Abov

bove the

the Cur

urve

Rem ove

ve Ch

Char

arge if

if Belo

low the Cu

Curve

ve

OutdoorO

u

td

o

o

r

CoilC

o

il

L

eavine

a

vi

n

g

Te

m

p

Te

m

p

eratue

ra

tu

re,re

,

[Deg[D

e

g

reesre

e

s

F]F

]

C07040

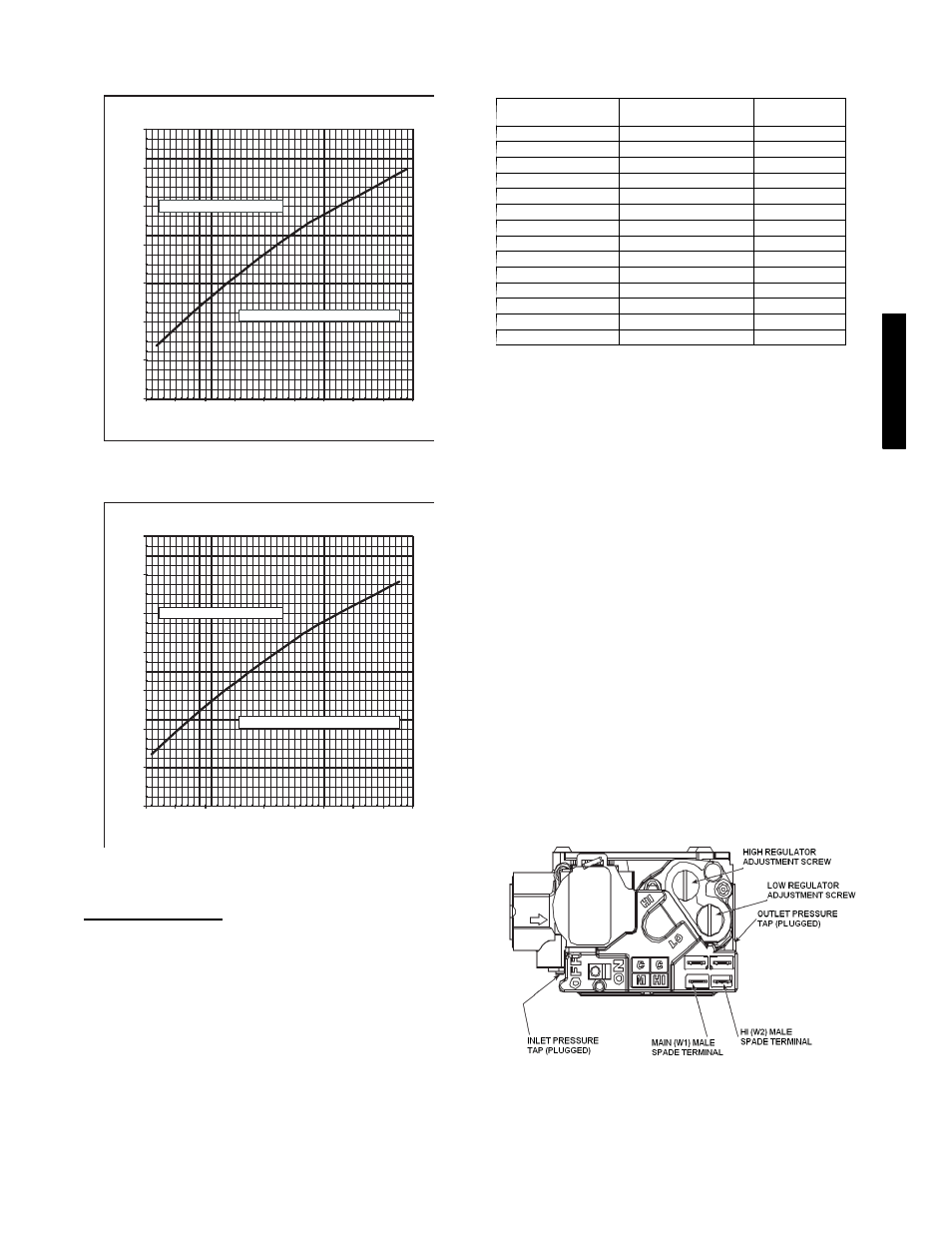

Fig. 35 -- Charging Chart ⎯ 48/50PD05

R4

R410A RE

REFRI

RIGERANT

RANT

OUTDOOR F

R FAN M

N M UST BE OPERATING ON H

N HIGH S

H SPEED

20

20

40

40

60

60

80

80

10

100

12

120

14

140

16

160

150

150

200

200

25

250

300

00

350

350

400

400

450

450

500

500

550

550

600

600

Co mp re ss

ssor Disc

isc h a rg e P re ss

ssu re , [p sig

sig]

Add

dd Cha

harge if Abov

bove the

the Cur

urve

Rem ove

ve Ch

Char

arge if

if Belo

low the Cu

Curve

ve

OutdoorO

u

td

o

o

r

CoilC

o

il

L

eavine

a

vi

n

g

Te

m

p

Te

m

p

eratue

ra

tu

re,re

,

[Deg[D

e

g

reesre

e

s

F]F

]

C07041

Fig. 36 -- Charging Chart ⎯ 48/50PD06

PuronR Refrigerant

Puron refrigerant operates at 50 to 70 percent higher pressures than

R-22. Be sure that servicing equipment and replacement

components are designed to operate with Puron refrigerant. Do not

mix with components that have been used with other refrigerants.

Puron refrigerant, as with other HFCs, is only compatible with

POE oils.

Recovery cylinder service pressure rating must be 400 psig. Puron

systems should be charged with liquid refrigerant. Use a

commercial-type metering device in the manifold hose. Manifold

sets should be 750 psig high-side and 200 psig low-side with 520

psig low-side retard. Use hoses with 750 psig service pressure

rating. Leak detectors should be designed to detect HFC

refrigerant.

Table 26 — Altitude Compensation*

48PG03--07

ELEVATION

(ft)

NATURAL GAS

ORIFICE†

PROPANE

ORIFICE†

0-1,999

45

52

2,000

47

52

3,000

47

53

4,000

47

53

5,000

48

53

6,000

48

53

7,000

48

53

8,000

49

54

9,000

49

54

10,000

50

54

11,000

51

54

12,000

51

55

13,000

52

55

14,000

52

56

*As the height above sea level increases, there is less oxygen per cubic foot of air.

Therefore, heat input rate should be reduced at higher altitudes. Includes a 4% input

reduction per each 1000 ft.

† Orifices available through your Carrier dealer.

Gas Valve Adjustment

The gas valve opens and closes in response to the thermostat or

limit control.

When power is supplied to valve terminals W2 (High Fire) and C1,

the main valve opens to its preset position.

The regular factory setting is stamped on the valve body.

To adjust regulator:

1. Set unit at setting for no call for heat.

2. Turn main gas valve to OFF position.

3. Remove

1

/

8

-in. pipe plug from manifold pressure tap

connection. Install a suitable pressure-measuring device.

4. Set main gas valve to ON position.

5. Set thermostat at setting to call for heat.

6. Remove screw cap covering regulator adjustment screw.

(See Fig. 37.)

7. Turn adjustment screw clockwise to increase pressure

or

counterclockwise to decrease pressure. The setting is 3.50

in. wg on sizes 03-14 and 3.00 on size 16--28.

8. Once desired pressure is established, set unit setting for no

call for heat, turn off main gas valve, remove

pressure-measuring device, and replace

1

/

8

-in. pipe plug and

screw cap.

C08663

Fig. 37 -- 48PD Gas Valve

48/

50P

D