Relief devices, Compressor sound shield, Control circuit, 24--v – Carrier 48/50PD05 User Manual

Page 67: Replacement parts, Diagnostic leds

67

Evaporator Fan Motor Protection

Indoor-fan motors less than 5 hp are equipped with internal

overcurrent and overtemperature protection. Protection devices

reset automatically. Disconnect and lock out power when servicing

motor. Indoor-fan motors 5 hp and larger are equipped with a

manual reset, calibrated trip, magnetic circuit breaker and

overcurrent protection. Do not bypass connections or increase the

size of the breaker to correct trouble. Determine the cause and

correct it before resetting the breaker.

Condenser--Fan Motor Protection

Each condenser-fan motor is internally protected against

overtemperature.

Fuses are located in the control box and feed power to the

condenser fan motors. Always replace blown fuses with the

correct size fuse as indicated on the unit fuse label.

Saturated Suction Pressure (SSP)

If the SSP for a particular circuit is reading below the alarm set

point for an extended period of time, that circuit will be shut down.

After 15 minutes, the alarm will automatically reset. If this alarm

occurs 3 times consecutively, the circuit will remain locked out

until an alarm reset is initiated via CCN or manually via the

Scrolling Marquee display (see Alarms and Alerts section for more

details).

Relief Devices

All units have relief devices to protect against damage from

excessive pressures (i.e., fire). These devices protect the high and

low side and are located at the suction line service port. Protect

joint during brazing operations near joint.

Compressor Sound Shield

The 48/50PD units are equipped with a compressor sound shield.

The sound shield has two parts, the compressor jacket encloses the

shell of the compressor and the base shield is installed between the

bottom of the compressor and the unit base pan. The sound shield

reduces the difference in noise levels as the compressor loads and

unloads in the frequency ranges of 200 to 2000 Hz. Since the

human speech occurs in the 200 to 2000 Hz frequency ranges the

sound shield reduces the speech annoyance caused by the loading

and unloading of the compressor.

The compressor jacket is held closed around the compressor by

Velcro tape. To remove the compressor jacket, separate the Velcro

along the side and top of the compressor. Slide the jacket toward

the back of the compressor to remove the jacket. Make sure the

jacket is reinstalled after servicing or replacing the compressor.

The compressor base shield is accessible when the compressor is

removed.

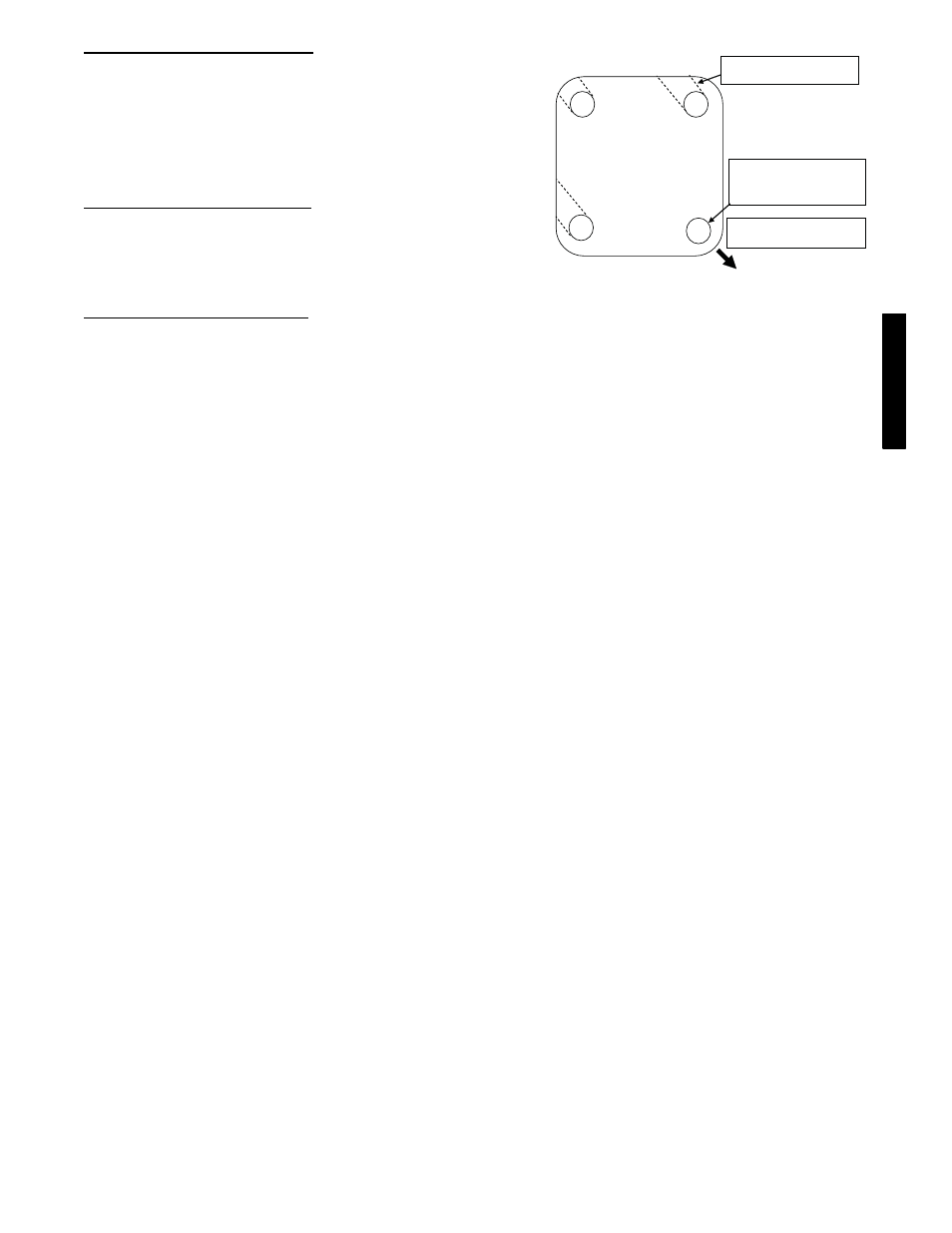

To remove the base shield without removing the

compressor, remove one front compressor mounting bolt and

grommet. At the three remaining compressor mounting grommets,

cut the sound shield so that the base shield can be slid in the

direction of the compressor mounting bolt and grommet that was

removed. (See Fig. 39.) Cut replacement base shield along dotted

lines as shown in Fig. 39 and reinstall in reverse direction. When

installing the base shield, place the soft side facing upward.

Reinstall compressor mounting grommet and bolt.

Remove this compressor

mounting bolt and grommet

at this location.

Slide Compressor Base Sound

Shield in this direction.

Cut Compressor Base Sound

Shield along dotted lines

COMPRESSOR BASE

SHIELD

C08664

Fig. 39 -- Base Sound Shield

Control Circuit, 24--V

Each control circuit is protected against overcurrent by a 3.2 amp

circuit breaker. Breaker can be reset. If it trips, determine cause of

trouble before resetting.

Replacement Parts

A complete list of replacement parts may be obtained from any

Carrier distributor upon request.

Diagnostic LEDs

The MBB, ECB, AUX1, IGC and DSC control boards have LED

lights for diagnostic purposes. The meanings and error codes can

be found in the the troubleshooting section of this manual.

48/

50P

D