High altitude, Main burners, Filter drier – Carrier 48/50PD05 User Manual

Page 66: Protective devices, Main burner removal, Cleaning and adjustment, Compressor rotation

66

High Altitude

For high altitude applications greater than 2,000 ft the heat input

rate should be reduced. The higher the altitude is above sea level,

the less oxygen is in the air. See Table 8 for orifice sizing. A high

altitude kit is available to convert unit for altitudes up to 7,000 ft.

Main Burners

For all applications, main burners are factory set and should require

no adjustment.

Main Burner Removal

1. Shut off (field-supplied) manual main gas valve.

2. Shut off power to unit.

3. Open gas section access door.

4. Disconnect gas piping from gas valve inlet.

5. Remove wires from gas valve.

6. Remove wires from rollout switch.

7. Remove sensor wire and ignitor cable from IGC board.

8. Remove 2 screws that hold the burner assembly to vestibule

plate.

9. Rotate the burner/manifold assembly to the right, away

from the flue extension and lift burner/manifold assembly

out of unit.

Cleaning and Adjustment

1. Remove burner rack from unit as described in Main Burner

Removal section above.

2. Inspect burners, and if dirty, remove burners from rack. The

two outer burners have the flame crossover closed off in

order to prevent gas flow from exiting the sides of the

burner assembly. To prevent ignition problems, make sure

the outer burners are returned to their original position when

done servicing.

3. Using a soft brush, clean burners and crossover port as

required.

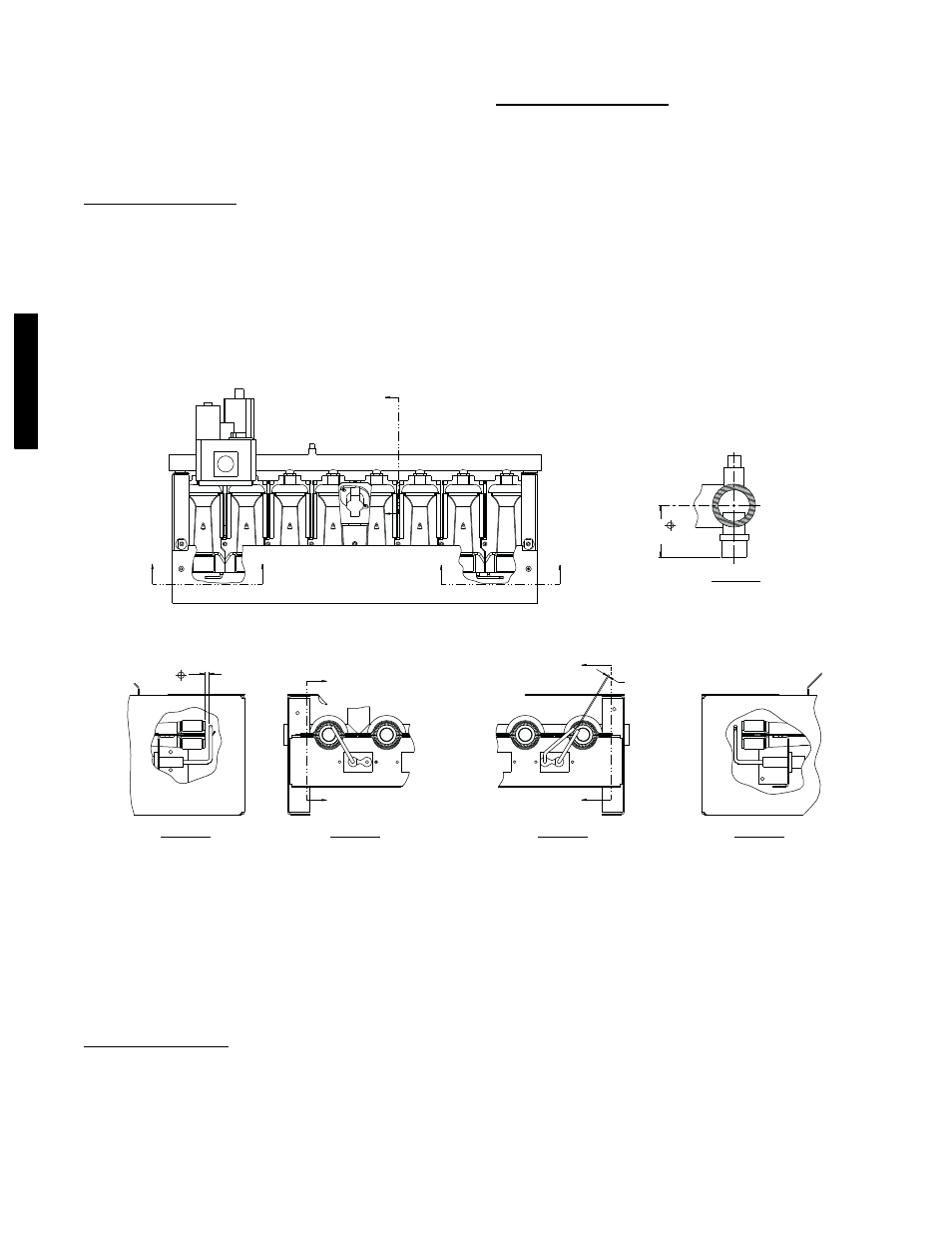

4. Adjust spark gap. (See Fig. 38.)

5. Reinstall burners on rack.

6. Reinstall burner rack as described above.

E

E

A

A

B

B

25.4

MAX. TYP.

SPARK GAP

0.120 TO 0.140”

[3.05 TO 3.56]

D

D

E-E

SECTION

SCALE 2:1

D-D

SECTION

B-B

SECTION

SCALE 1:1

A-A

SECTION

SCALE 1:1

C-C

SECTION

C

C

SPARK GAP

0.181”

[4.6]

C06269

Fig. 38 -- Spark Gap Adjustment

Filter Drier

Replace filter drier whenever refrigerant system is exposed to

atmosphere. Only use factory specified liquid-line filter driers with

working pressures no less than 650 psig. Do not install a

suction-line filter drier in liquid line. A liquid-line filter drier

designed for use with Puron® refrigerant is required on every unit.

Protective Devices

Compressor Rotation

Overcurrent

Each compressor has internal line break motor protection.

Overtemperature

Each compressor has an internal protector to protect it against

excessively high discharge gas temperatures.

High--Pressure Switch

If the high-pressure switch trips, the compressor will shut down

and the current sensor (3-phase units only) will not detect current.

See the Current Sensor section below for more information.

Current Sensor (CS) (3--Phase Units Only)

The purpose of the CS is to detect losses in compressor power.

After detecting a loss in compressor power, unit control locks out

the compressor for 15 minutes. After 15 minutes, the alarm will

automatically reset. If this alarm occurs 3 times consecutively, the

compressor will remain locked out until an alarm reset is initiated

via CCN or manually via the Scrolling Marquee display (see

Alarms and Alerts section for more details).

IMPORTANT: The current sensor is not currently used in the

48/50PD, but reserved for future implementation.

48/

50P

D