Rockwell Automation 7000 PowerFlex Medium Voltage (B Frame) Commissioning - ForGe (PanelView 550) User Manual

Page 59

Rockwell Automation Publication 7000-IN006B-EN-P - May 2013

55

Commissioning the Drive Chapter 5

1. Lock out and isolate the drive from medium voltage. Verify with a hot stick

that there is no medium voltage present.

2. Determine that the key interlock is correctly aligned by securely bolting

the medium voltage doors of the cabinet closed and removing the key from

the lock. The key should turn easily; if any force is required to turn the key,

the deadbolt alignment requires adjustment.

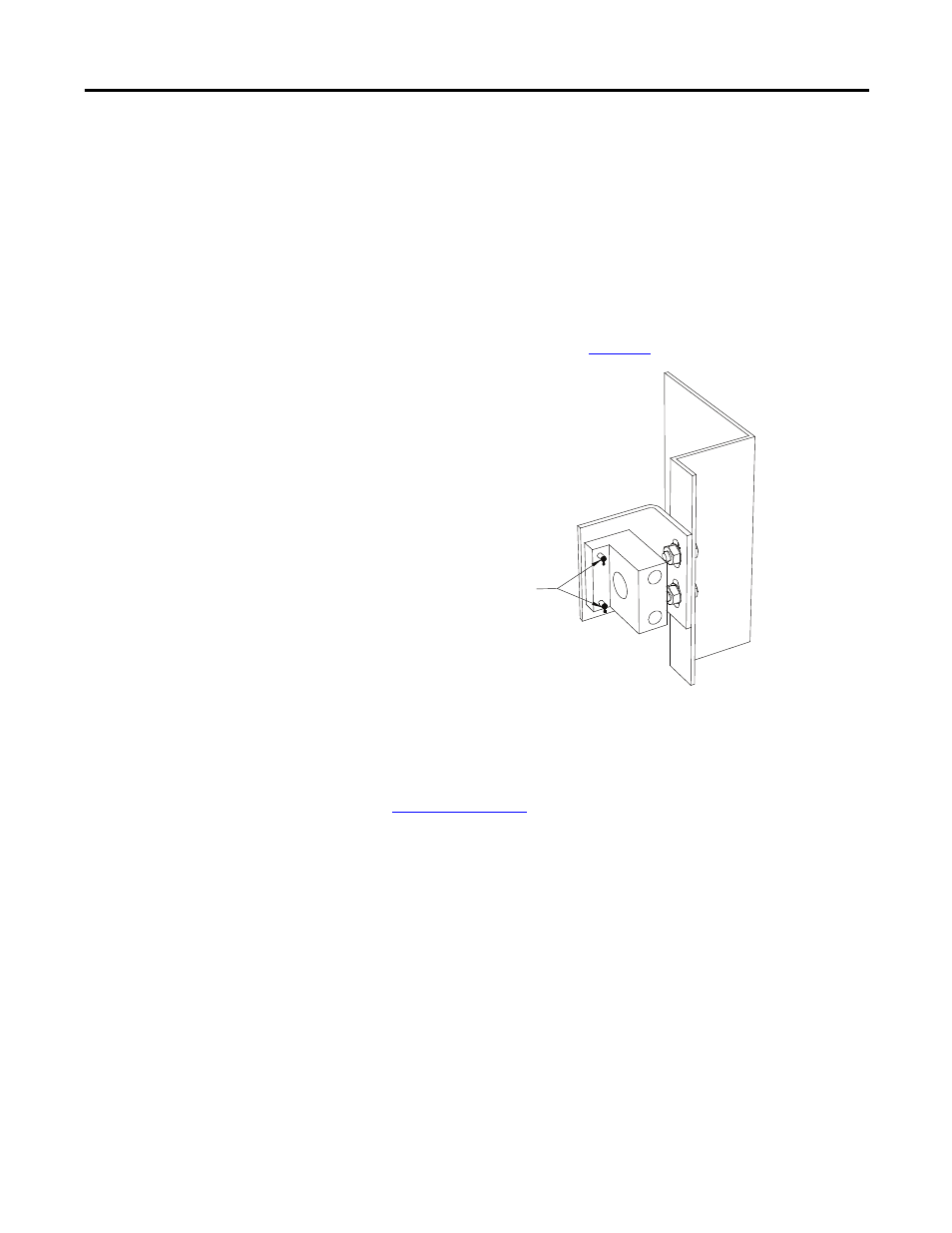

3. Open the doors of the cabinet and inspect the key assembly. Place high

visibility grease on the pins of the deadbolt counterpart. The factory

recommends using yellow torque sealant, however if it is unavailable

almost any grease will do. (See

Figure 31 - Deadbolt counterpart mounted to cabinet

4. Bolt the cabinet door closed so the pins on the dead bolt counterpart make

contact with the deadbolt assembly. Doing so should leave two marks of

torque sealant or grease on the assembly where the pins made contact (see

).

5. Slightly loosen the adjustment bolts on the counterpart and make the

necessary movements on the counterpart to ensure that the pins align with

the landing plates on the deadbolt assembly. As the amount of counterpart

movement required is an estimate, it may take a couple attempts to

properly align the assembly.

6. Clean the torque seal/grease from the key interlock once finished aligning

the counterpart.

Once properly aligned, the key should turn freely when the cabinet door is fully

bolted shut. If the key does not function when the door is tightly bolted closed,

adjustments will have to be made to the depth of the counterpart. This can be

done by adding shims on the landing plate where the counterpart is mounted.

Place grease on

deadbolt pins here.