Summary – Rockwell Automation 1785-Lx0C15 ControlNet PLC-5 Programmable Controllers User Manual User Manual

Page 67

1785-UM022C-EN-P - February 2008

Planning to Use Your ControlNet PLC-5 Processor

2-29

Summary

There are two methods to optimize the use of I/O image table in a

ControlNet PLC-5 processor. There are tradeoffs in using each

method which are summarized in the following table.

The best solution in most cases is to combine the two methods.

Examine the module requirements at any given chassis or location

and see which method fits best. You may find in some areas you have

an equal number of input and output modules, and slot

complementary optimizing works well. However, you may find in

other areas there are space limitations which require the use of the

smallest possible chassis, and therefore, you cannot waste slots using

slot complementary.

A final point to be aware of is that each system is unique and you

must apply these techniques accordingly. For example, you may have

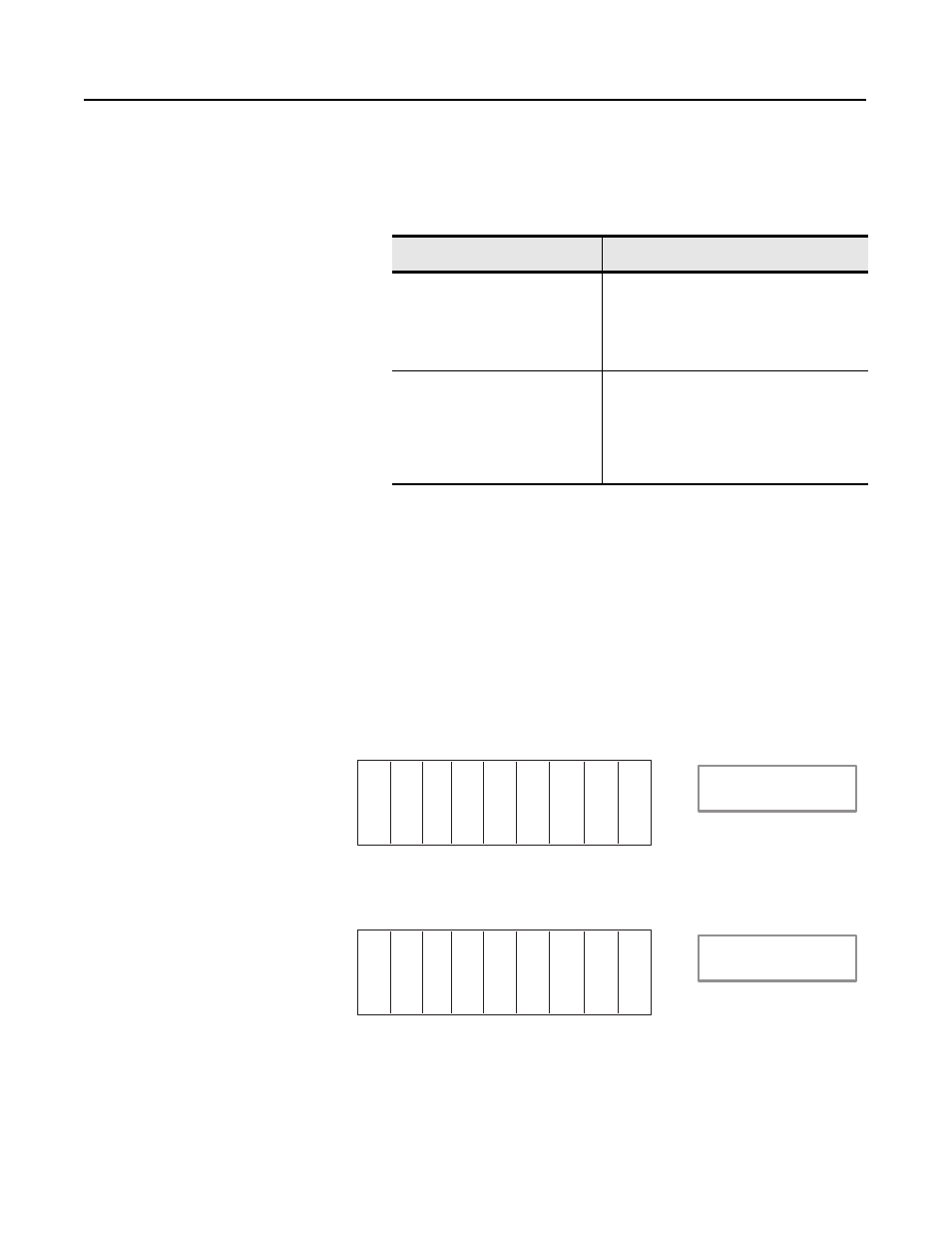

the following chassis:

Using strict rules of optimization you might immediately arrange the

chassis like this:

Method:

Tradeoffs:

optimize without slot

complementary

• allows optimization of I/O image table, but

not to the extent if using slot complementary

• does not waste chassis slots

• can put any module anywhere (provided I/O

table exists for that slot)

optimize with slot complementary

• allows complete optimization of the I/O

image table

• can waste chassis slots and require

additional chassis

• can only put modules in odd or even slots,

depending on the module type

I

I

O

I

I

I

I = Discrete Input Module

O = Discrete Output Module

ACN = ControlNet adapter

O

I

ACN

2-slot addressing

16-point modules

O

O

I

I

I

I

I = Discrete Input Module

O = Discrete Output Module

ACN = ControlNet adapter

I

I

ACN

2-slot addressing

16-point modules