Using i/o mapping techniques – Rockwell Automation 1785-Lx0C15 ControlNet PLC-5 Programmable Controllers User Manual User Manual

Page 59

1785-UM022C-EN-P - February 2008

Planning to Use Your ControlNet PLC-5 Processor

2-21

Other ControlNet Processors

ControlNet scheduled peer-to-peer communications between

ControlNet processors require one map-table entry per message.

You can set up ControlNet peer-to-peer communications between any

two processors on a ControlNet network. The ControlNet transfer

mechanism makes it possible to map the scheduled peer-to-peer

messages listed in the following table.

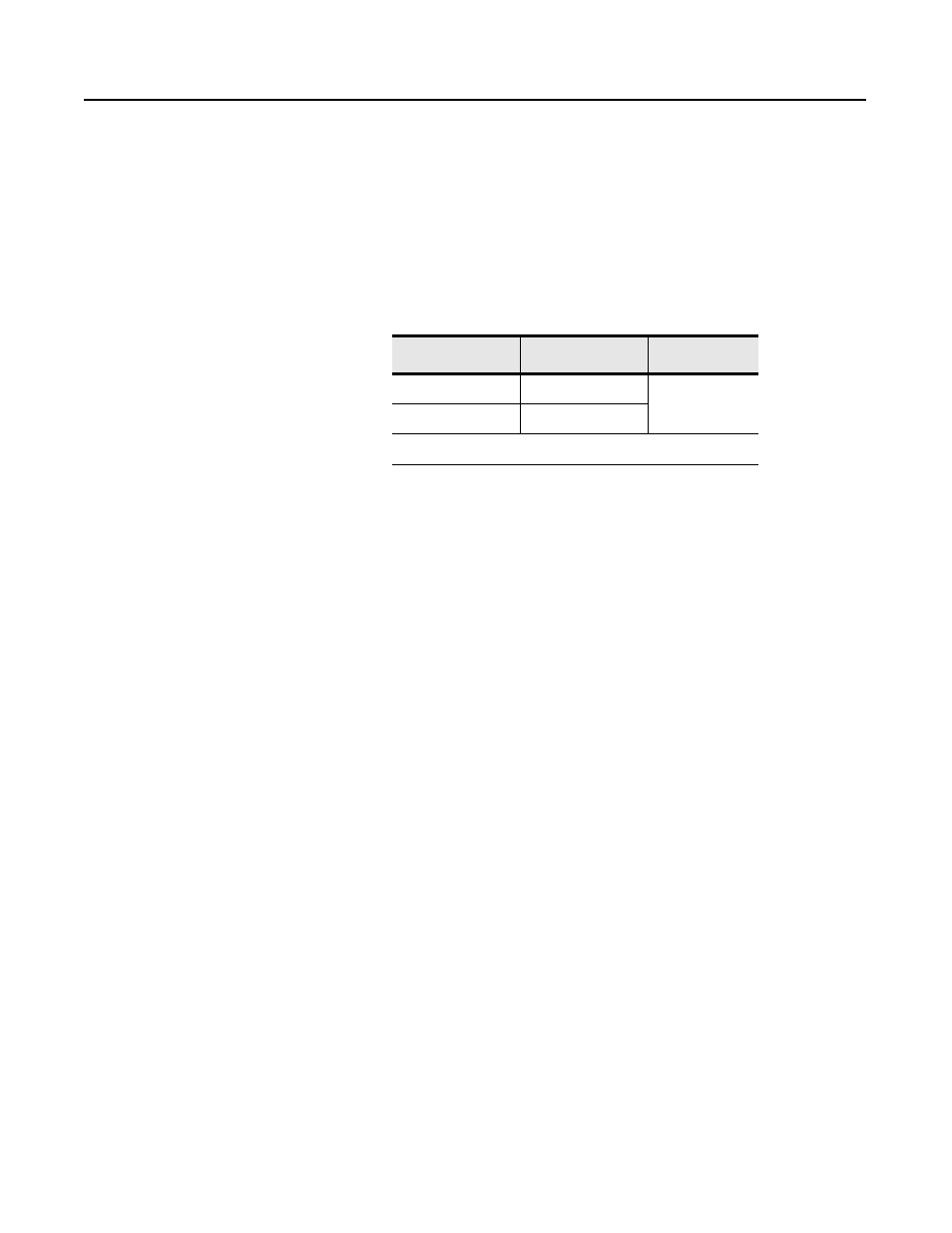

Table 2.F Peer-to-Peer Communications Mapping

To communicate between any ControlNet PLC-5 processors on the

ControlNet network, you can include MSG instructions in your

ladder-logic program. See Chapter 4 and Appendix C for more

information.

Using I/O Mapping Techniques

Discrete I/O interfaced to a PLC-5 processor is typically mapped to

the I/O image table. You can map discrete I/O to the DIF and DOF,

but you lose the ability to force the I/O if the DIF or DOF is used.

Each version of the PLC-5 processor has a specific amount of I/O

image table available, and therefore, a limit on the amount of I/O that

can be mapped to the I/O image table. Traditionally, each slot in an

I/O chassis is assigned a location in the input image table and the

output image table. While this provides very easy mapping of I/O to

the image table, it is not the most efficient way to use it. For example,

if a slot contains an input module, the corresponding location in the

output image table goes unused. With the introduction of the

ControlNet network to the PLC-5 processor family, new techniques

are available to map discrete I/O into the I/O image table in a more

efficient manner.

Input and output data can be mapped to offsets within the I/O image

tables and need not be the same size.

Message Type

Description

1

Valid Sizes

Receive Data From

Scheduled Message

1-240 words

Send Data

Scheduled Message

1

RPI Default = 4 x NUT