In-Situ TROLL 9500 Operators Manual User Manual

Page 87

80

TROLL 9500 Operator’s Manual

0095110 rev. 007 01/09

4. Thread the membrane module to the D.O. sensor.

Be sure the membrane does not leak. You should not see

any drops on the surface. There should be no visible air

bubbles.

5. Install and condition the sensor as described below. Then you’re

ready to calibrate.

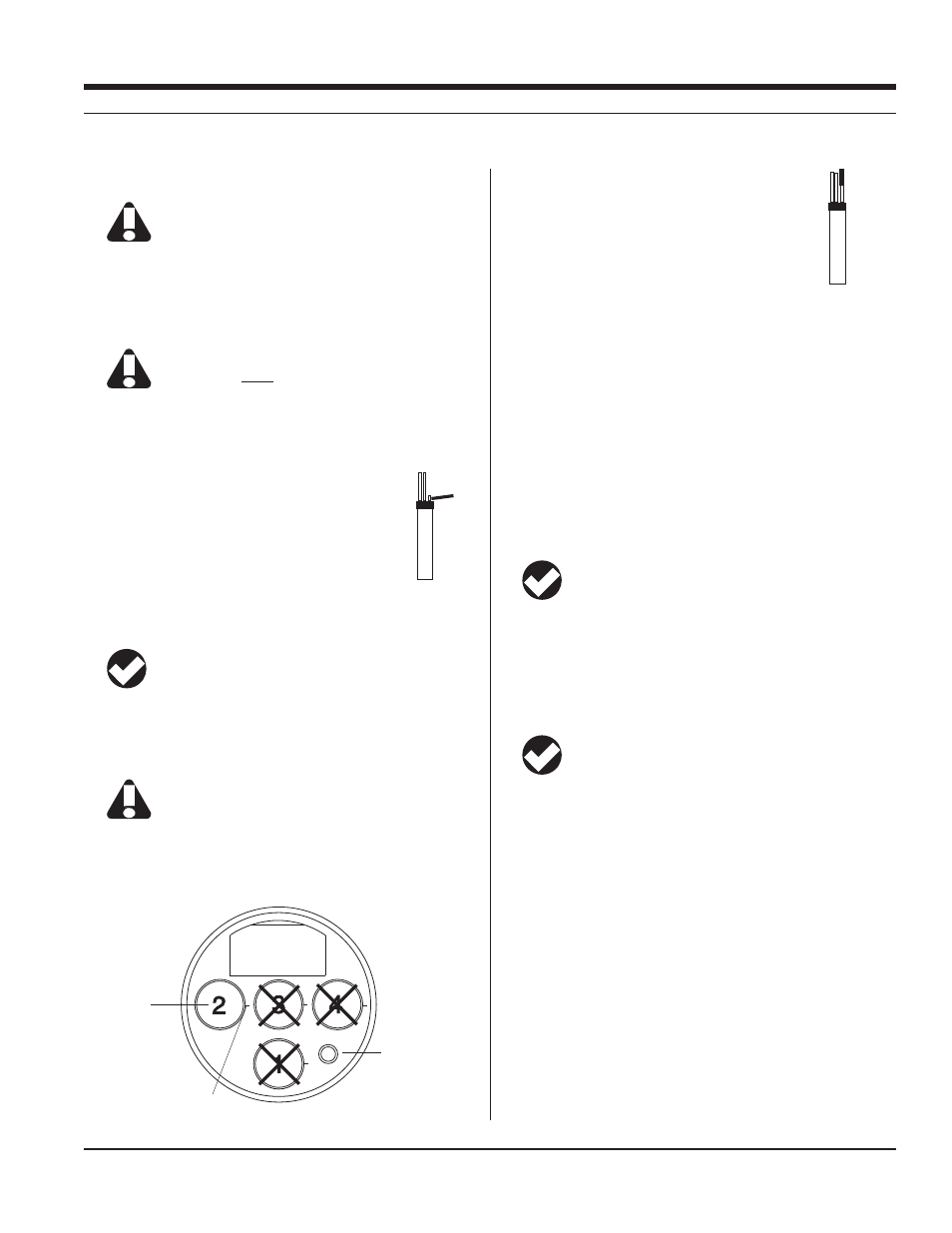

INSTALL THE SENSOR IN THE MP TROLL 9500

The polarographic D.O. sensor will function properly only

when installed in port 2.

1. Remove the restrictor or Cal Cup from the front end of the MP

TROLL 9500. This allows access to the sensor block shown in the

drawing below.

2. Remove any moisture or dirt from the area around

port 2, then use the sensor removal tool to remove

the plug or sensor from port 2. Retain the plug for

future use.

3. Remove any moisture or dirt from the port connector

with a clean swab or tissue.

4. Check lubrication of the sensor o-rings.

TIP: The sensor o-rings require generous lubrication before

installation. New sensors will be lubricated at the factory. If

the o-rings appear dry, apply a silicone lubricant before installation.

5. Handling the sensor by the sides, not the tip, align the mark on the

side of the sensor with the mark on the port.

Avoid touching the membrane at the tip of the sensor.

Contaminants on the membrane can change its properties

and affect measurements.

6. Use the sensor insertion tool to press the sensor into the port until

you feel it dock with the connector at the bottom. When properly

inserted a small gap (width of the sensor removal

tool) remains between the widest part of the sensor

and the instrument body, for ease of removal.

7. Turn the sensor “on” and condition it, as described

next.

CONDITION A NEWLY INSTALLED SENSOR

Condition a new sensor, or one with a new membrane, as follows:

1. Fill and install the sensor as described above.

2. Connect the MP TROLL 9500 to a PC and establish a connection

in Win-Situ 4 or Pocket-Situ 4.

3. Select the MP TROLL 9500 in the Navigation tree. All installed sen-

sors will be displayed.

Powering of the D.O. sensor begins as soon as the software rec-

ognizes the D.O. sensor and displays it in the Navigation tree. This

starts the conditioning process.

TIP: If you plan to calibrate 100% D.O. in air, condition the

sensor in a moist environment at ambient pressure—the

loosely attached Cal Cup with a small amount of clean water is ideal.

If you will be calibrating 100% D.O. in water, condition the sensor dry.

We recommend that you allow the sensor to condition for 2-10 hours

before calibrating. Testing has shown that 10 hours of conditioning

yields very stable long-term performance.

TIP: It is not necessary to maintain the computer connection;

conditioning continues as long as the sensor is installed.

CALIBRATION

OVERVIEW

Several options are available for calibrating a polarographic sensor.

s

D.O., conductivity) at the same time with one convenient solution.

This is a 1-point 100% D.O. calibration in air at ambient pressure.

s

either in air (saturated with water) at ambient pressure, or in water

(saturated with air—for example, using a bubbler). The water

method is generally more accurate, as it better represents actual

field D.O. measurement conditions.

s

either in air or in water. 0% D.O. is calibrated in an oxygen-

sensor

removal

tool

sensor

insertion

tool

SECTION 13: DISSOLVED OXYGEN—POLAROGRAPHIC

Install polaro-

graphic D.O.

sensor here

Pressure/Turbidity

(or plug)

Temperature

alignment mark