In-Situ TROLL 9500 Operators Manual User Manual

Page 110

105

TROLL 9500 Operator’s Manual

0095110 rev. 007 01/09

SENSOR INSTALLATION

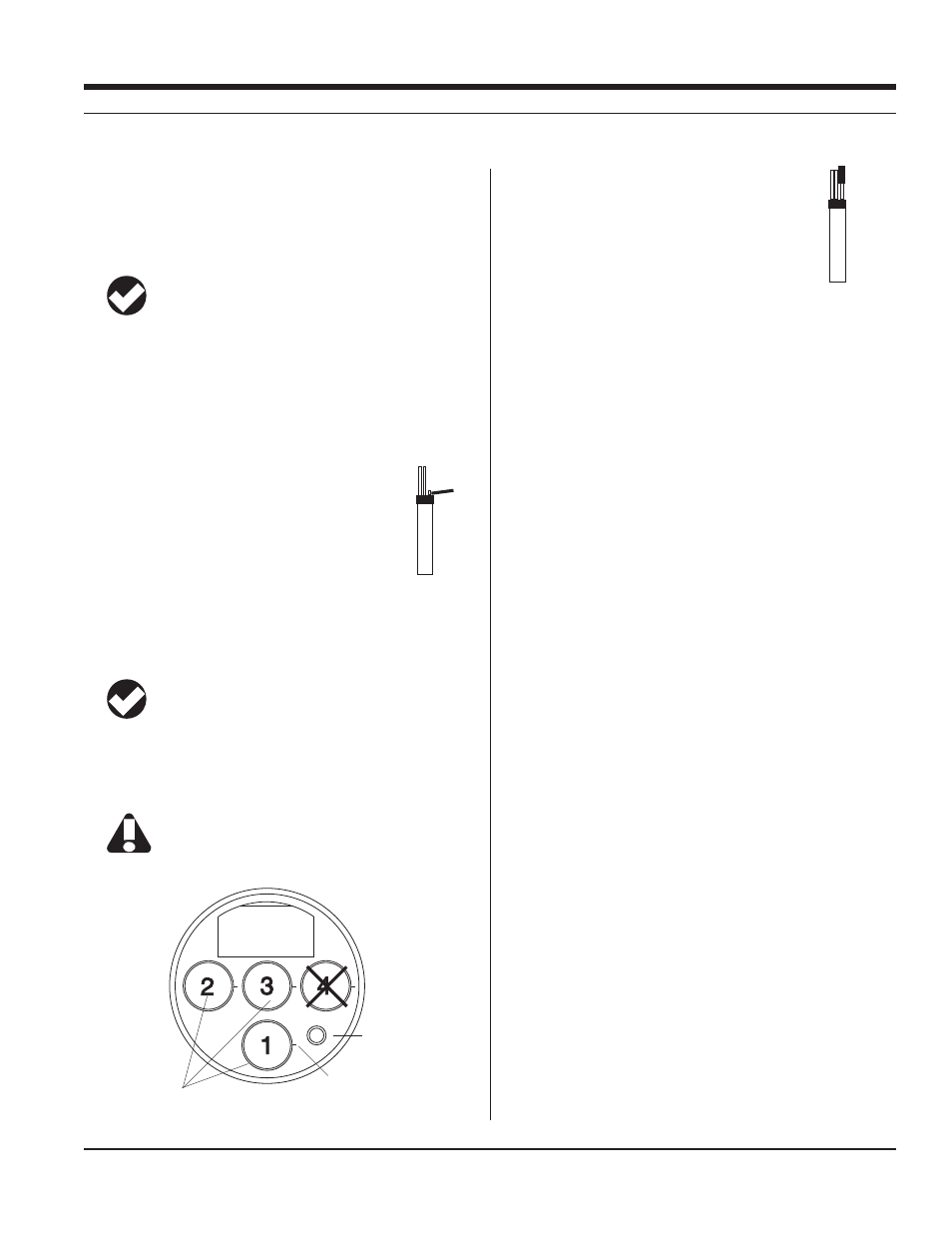

Unpack the ammonium sensor, hydrate it as above, and install in port

1, 2, or 3 in the sensor block at the front end of the MP TROLL 9500

as follows.

TIP: Remember that a polarographic D.O. sensor (if present)

will operate properly only in port 2 and a turbidity wiper

accessory only in port 3.

1. Remove the restrictor from the front end of the MP TROLL 9500.

This allows access to the sensor block depicted in the drawing

below.

2. Remove the sensor’s protective cap or storage bottle and set aside

for future storage of the sensor. If the connector end is covered

with a cap, remove it also.

3. Remove any moisture or dirt from the area around

the port where you will install the sensor, then use the

sensor removal tool to remove the plug from the port

where you will install the sensor.

4. Remove any moisture or dirt from the port connector with a clean

swab or tissue.

5. Check lubrication of the sensor o-rings.

TIP: The sensor o-rings require generous lubrication before

installation. New sensors will be lubricated at the factory. If

the o-rings appear dry, apply apply a silicone lubricant before

installation.

6. Handling the sensor by the sides, not the tip, align the mark on the

side of the sensor with the mark on the port.

Avoid touching the membrane at the tip of the sensor.

Contaminants on the membrane can change its properties

and affect measurements.

7. Use the sensor insertion tool to firmly press the

sensor into the port until you feel it dock with the

connector at the bottom. When properly inserted a

small gap (width of the sensor removal tool) remains

between the widest part of the sensor and the instru-

ment body, for ease of removal.

CALIBRATION

OVERVIEW

The software offers several options for ammonium calibration.

s

two calibration points are taken in solutions of different concentra-

tions at the same temperature. The third point uses one of these

SOLUTIONS

s

tions of two different concentrations. A two-point isothermal calibra-

tion calculates the sensor’s slope and offset but cannot compute

the isopotential point. For best results this type of calibration should

be carried out as close as possible to the temperature at which the

sensor will be used. Or, It may be performed after a previous three-

point bithermal calibration to recalculate the slope and offset of an

aging sensor while retaining the previously calculated isopotential

point.

s

bration has established the sensor slope, offset, and isopotential

point, a single-point calibration may be used with good results to

adjust the offset on a daily basis.

CALIBRATION SOLUTIONS

Ammonium chloride (NH

4

Cl) solutions certified to N.I.S.T. standards

are supplied in the In-Situ Ammonium Calibration Kits:

14.0 ppm as N

140 ppm as N

1400 ppm as N

sensor

removal

tool

sensor

insertion

tool

Pressure/Turbidity

(or plug)

Temperature

Ammonium sensor may be installed

in port 1, 2, or 3

alignment mark

SECTION 15: AMMONIUM