In-Situ TROLL 9500 Operators Manual User Manual

Page 58

51

TROLL 9500 Operator’s Manual

0095110 rev. 007 01/09

INSTALLATION FOR PRESSURE/LEVEL MEASURE-

MENT

Position the instrument below the lowest anticipated water level, but

not so low that its range might be exceeded at the highest anticipated

level. Lower the MP TROLL 9500 gently to the desired depth.

If real-time readings are not required, remove the TROLL Com from

the cable after programming. Protect the “uphole” end of the cable

with the dust cap or optional desiccant. If cable will not be used, at-

tach a Twist-Lock Hanger to the TROLL 9500.

SECURING THE CABLE

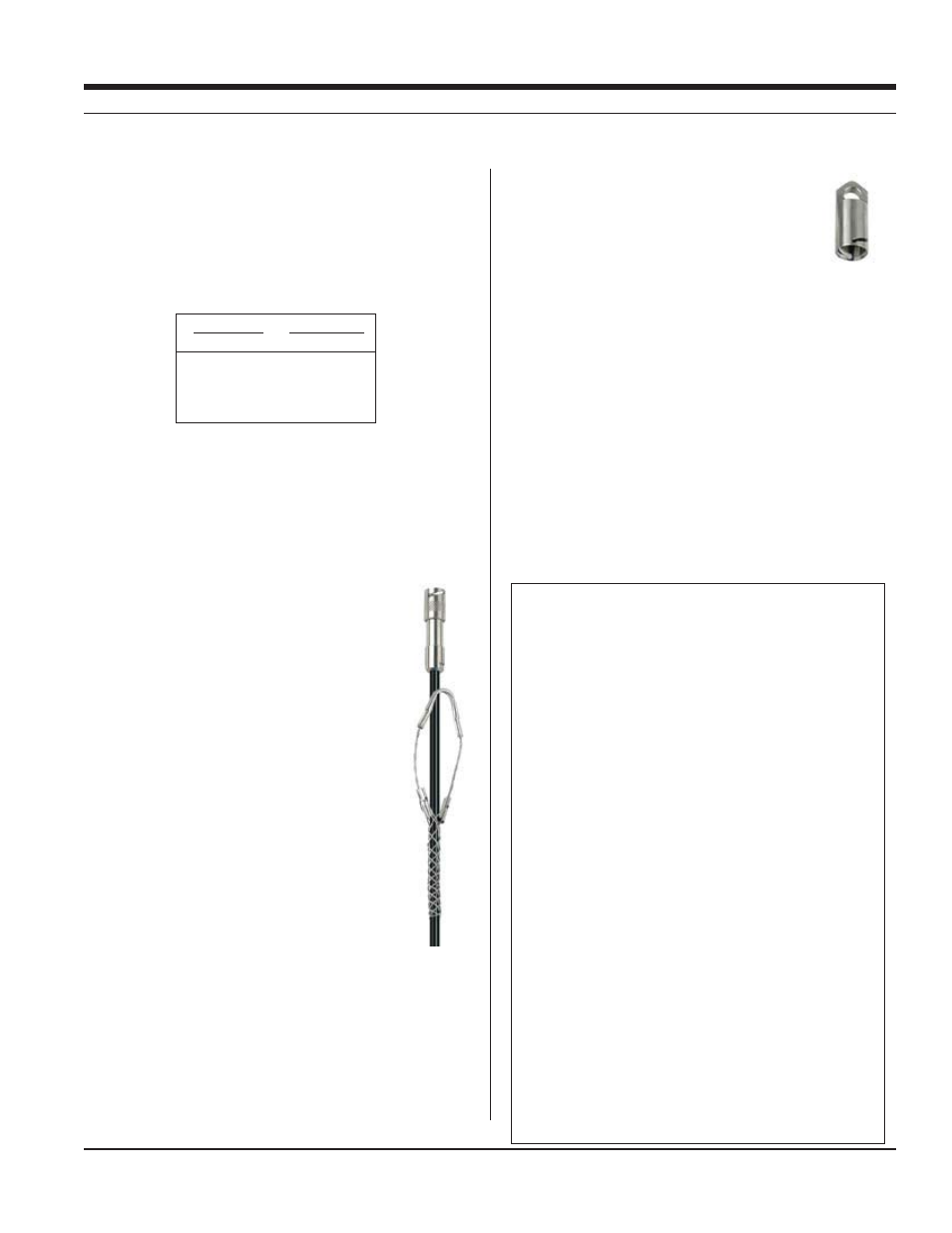

The RuggedCable has a handy device called a Kellems® grip near

the surface end. You can slide it along the cable to

the desired position by compressing it. When you

pull on it, it tightens and stops sliding. You may need

to pull on both ends of the Kellems grip to properly

tighten it and keep it from slipping.

Use the loop of the Kellems grip to anchor the cable

to a convenient stationary object. It works well with

In-Situ’s “well dock” installation ring. Simply insert

the loop into the locking clip on the well dock, and

position the assembly on the top of a well. Insure the

cable is secured to prevent the instrument moving

while data is being logged.

STABILIZATION TIME

Allow the instrument to stabilize to the water condi-

tions for about an hour before starting a test. A gen-

erous stabilization time is always desirable. Even

though the cable is shielded, temperature stabiliza-

tion, stretching, and unkinking can cause apparent

changes in the probe reading. If you expect to

monitor water levels to the accuracy of the probe, it’s worth allowing

the extra time for the probe to stabilize to the test environment.

TWIST-LOCK HANGER INSTALLATIONS

The non-vented Twist-Lock hanger accessory can be

used to suspend a pre-programmed MP TROLL 9500

in a well or other site while taking data where baromet-

ric pressure changes are not crucial.

The Twist-Lock hanger allows use of inexpensive

hanging cable, and requires no direct communication and no cable

venting. This setup is ideal for use where barometric compensation of

pressure measurements is not required—in vacuum testing, uncon-

fined aquifers, or very deep applications where barometric pressure

effects are minimal.

s

ties, you must program the MP TROLL 9500 before installation

s

metric pressure. However, post-processing tools may be used

to eliminate the effects of barometric pressure changes from the

data, if required. See “Correcting Absolute Pressure Readings for

Barometric Pressure” below for more information.

SECTION 7: MONITORING PRESSURE (WATER LEVEL)

Range

Usable

Depth

kPa PSI

Meters Feet

103.4

15

11

35

206.8

30

21

69

689.5 100

70 231

2068 300

210 692

Pressure Sensor Pressure Ratings

Kellems grip

Installation Tips for Level/Depth/Pressure Monitoring

s

wave when it hits the water surface can damage the pres-

sure sensor strain gauge (the “waterhammer” effect), as well

as other sensors.

s

probe, then move it and read again to be sure that the probe

is giving a reasonable reading and showing change. It might

not be located where you think it is — for example, it could

be wedged against the casing with a loop of cable hanging

below it. A probe in such a position might become dislodged

and move during the test, giving a false change in level. A

secure placement is critical to accurate level measurements.

s

the cable (and its internal vent tube) to kink or bend. If the

vent tube is obstructed, water level measurements can be

adversely affected. The vent tube can become kinked and

damage the internal components without any visible harm to

the outside of the cable. The recommended minimum bend

radius is 63.4 mm (about 2½ in) or more.

s

in a pumping well. The pressure transients generated by

the pump will cause false level readings. Large pumps can

swallow the probe and cause permanent damage to both

the MP TROLL 9500 and the pump.